The All-Too-Common Bottleneck

Every successful apiary eventually faces the same, sticky problem. The harvest is good, the honey is exceptional, and demand is growing. Yet, the fulfillment room has become a bottleneck. Hand-bottling, once a point of artisanal pride, is now a source of inconsistency, wasted product, and mounting frustration.

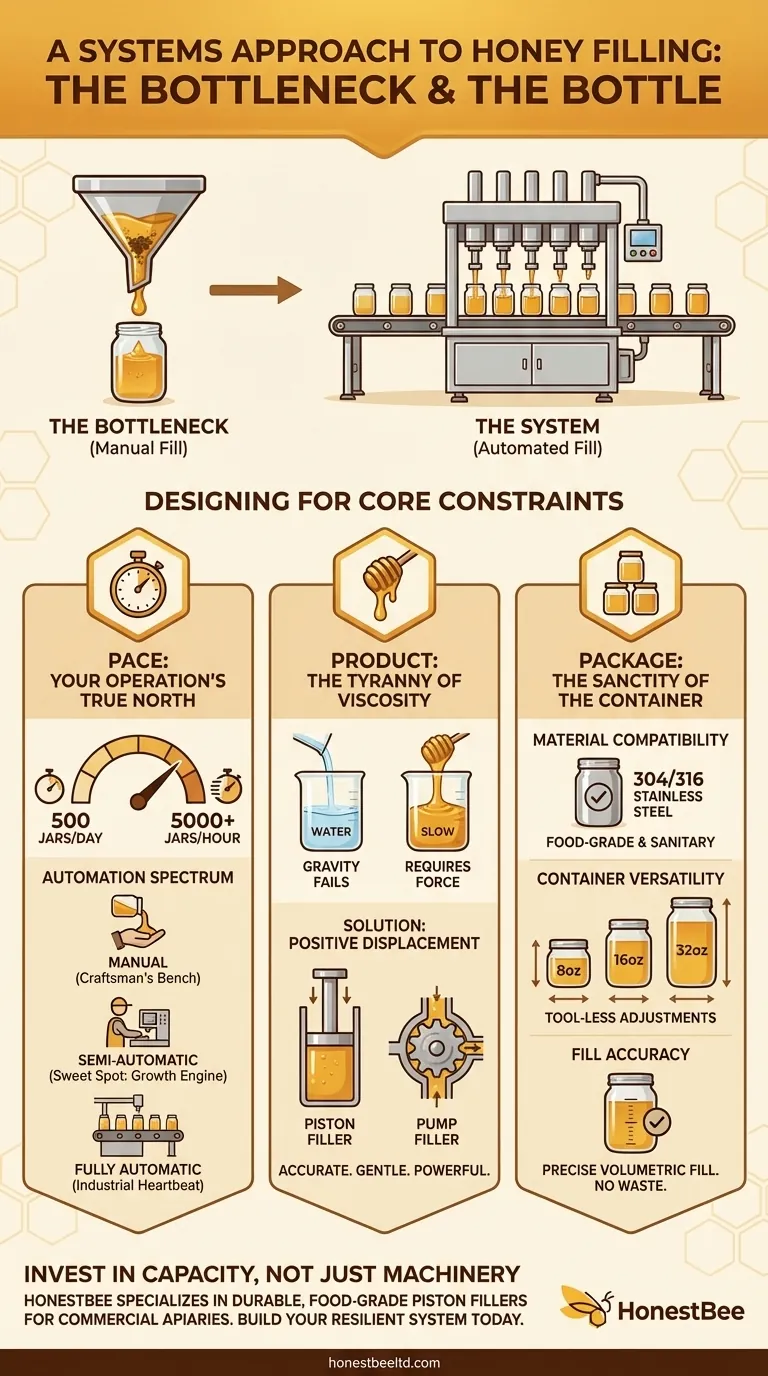

The instinct is to search for a "machine." But this is a psychological trap. We are drawn to lists of features, impressive speeds, and complex machinery, believing that more technology is the solution. The reality is that buying equipment is not the goal. The goal is to design a better production system.

The most robust systems are not defined by their complexity, but by their elegant alignment with a few core constraints. For filling honey, or any liquid, these are the only three variables that truly matter: your Product, your desired Pace, and your Package.

Pace: Your Operation's True North

Before you look at a single piece of stainless steel, you must have an honest conversation about speed. This number is the compass for your entire investment.

The Honest Question of Speed

How fast do you really need to fill? Your target fill rate—measured in bottles per minute (BPM)—is not a vanity metric. It's a declaration of your business's scale.

- 500 jars a day? Your needs are about consistency and reliability.

- 5,000 jars an hour? Your world is defined by uptime and throughput.

Be realistic about your current demand and, more importantly, your projected growth over the next two years. This single metric will immediately narrow your options from dozens to a select few.

The Automation Spectrum: A Strategic Choice

Your required pace dictates the right level of automation. This isn't just a technical decision; it's a choice about capital allocation and labor.

- Manual Fillers: The craftsman's bench. Excellent for developing new infusions or filling a handful of special orders. They are inexpensive but become a liability when consistency and volume are required.

- Semi-Automatic Fillers: The engine of growth for most commercial apiaries. An operator places the jars, but the machine delivers a precise, repeatable fill every time. This is the sweet spot, balancing capital investment with a massive leap in productivity and professionalism.

- Fully Automatic Fillers: The industrial heartbeat. These systems are essential for high-volume operations supplying regional or national distributors. They are incredibly efficient for a single jar type but demand significant capital and can be inflexible.

Product & Package: The Physical Laws of Your Liquid Gold

The nature of your honey and the jars you fill it into are non-negotiable physical realities. Your machine must obey these laws.

The Tyranny of Viscosity

Honey is not like water. Its viscosity—its resistance to flow—is its defining characteristic. It changes with temperature, floral source, and moisture content. A simple gravity filler, which works perfectly for thin liquids, will fail spectacularly with thick, viscous honey.

You need a machine that can apply force.

- Piston Fillers: The workhorse for viscous products like honey, sauces, and creams. A piston draws a precise volume of product into a cylinder and then positively displaces it into the container. This method is accurate, gentle, and powerful enough to handle even the thickest crystallized honey.

- Pump Fillers: Another excellent choice, offering flexibility for a range of viscosities. They use a pump (like a lobe or gear pump) to move the product.

Ignoring viscosity is the single most common technical mistake in choosing a filling machine. It's the difference between a smooth, efficient process and a daily cleaning disaster.

The Sanctity of the Container

Your jar is a promise to your customer. The machine you choose must honor that promise, from the first bottle to the last.

| Constraint | Why It Matters | The Right Solution |

|---|---|---|

| Material Compatibility | Honey is a food product. Any surface it touches must be inert and easy to sanitize to prevent contamination and preserve flavor. | Insist on food-grade 304 or 316 stainless steel for all contact parts. No exceptions. |

| Container Versatility | Your business may sell 8oz, 16oz, and 32oz jars. Your filler must adapt without hours of mechanical surgery. | Look for equipment with simple, tool-less adjustments for container height, diameter, and fill volume. |

| Fill Accuracy | Over-filling gives away product and profit. Under-filling damages customer trust. | A quality piston or pump system provides volumetric accuracy that manual pouring can never match. |

A Machine Is a Hypothesis About Your Future

Choosing a filling machine is an investment in your operational capacity. The wrong machine creates more problems than it solves. The right one doesn't just fill bottles; it removes a barrier to growth.

By focusing on the three core constraints—Product, Pace, and Package—you move from buying a piece of equipment to designing a resilient system. You replace a list of confusing features with a clear understanding of your operational reality.

HONESTBEE specializes in supplying durable, food-grade stainless steel filling equipment designed for the unique challenges of commercial apiaries. Our wholesale solutions, particularly our robust piston fillers, are engineered to handle the high viscosity of honey with precision and reliability. We understand that your success depends on a system that works, day in and day out. Let us help you build it right. Contact Our Experts

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity