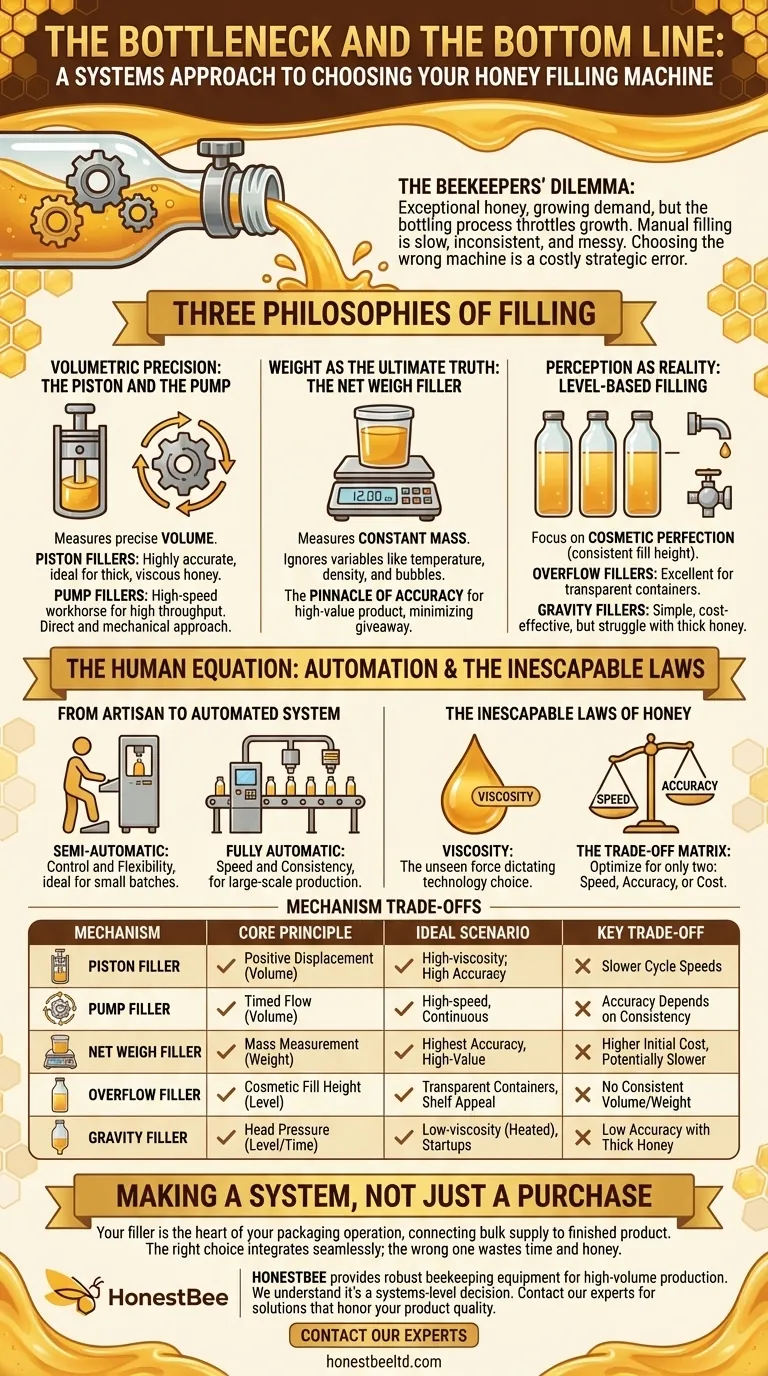

The Beekeepers' Dilemma

Every successful commercial beekeeper eventually faces the same, sticky problem. The honey is exceptional, the demand is growing, but the process of getting that liquid gold from a bulk tank into a jar is a bottleneck that throttles growth.

The romance of the harvest gives way to the tedious reality of bottling. Manual filling is slow, inconsistent, and messy. The decision to invest in a filling machine feels obvious, but the path forward is anything but. Choosing the wrong machine isn't just an equipment mistake; it's a strategic error that can cost thousands in wasted product and inefficiency.

Three Philosophies of Filling

At its heart, every filling machine subscribes to one of three core philosophies for measuring honey: filling by volume, by weight, or by level. Understanding which philosophy aligns with your operation is the first step toward clarity.

Volumetric Precision: The Piston and the Pump

This is the most common approach. A volumetric filler is engineered to dispense a precise, repeatable volume of honey every single time.

- Piston Fillers act like a large syringe. A piston pulls a set amount of honey into a cylinder and then pushes it into your container. It's a deliberate, mechanical, and highly accurate action, making it the industry standard for thick, viscous honey.

- Pump Fillers use the controlled rotation of a gear or lobe to move honey. The volume is determined by how long the pump runs or how many rotations it completes. This method is built for speed and is a workhorse in high-throughput production lines.

The psychological appeal of volumetric filling is its directness. You are selling a pint of honey, so you dispense a pint of honey.

Weight as the Ultimate Truth: The Net Weigh Filler

A net weigh filler operates on a more fundamental principle: mass is constant. It places a container on a scale, tares the weight to zero, and fills until a target weight is reached.

This method is the pinnacle of accuracy. It completely ignores variables that can fool volumetric systems, such as:

- Temperature changes that alter honey's density.

- Micro-bubbles that take up space but have negligible weight.

- Variations in density between different honey varietals.

For operations where product cost is high and giveaway is a critical metric, filling by weight is the only way to guarantee that a 12-ounce jar contains exactly 12 ounces of product.

Perception as Reality: Level-Based Filling

Some machines don't care about the exact volume or weight. Their only job is to make every container look the same on the shelf.

- Overflow Fillers are designed for cosmetic perfection. They fill bottles to a specific height, allowing excess product to "overflow" back into a tank. This is essential for transparent containers, where a customer's eye is immediately drawn to any inconsistency in fill levels.

- Gravity Fillers are the simplest of all. A tank sits above the nozzles, and a valve opens to let gravity do the work. While cost-effective, they struggle with thick honey and depend on consistent product viscosity—often requiring you to heat your honey, which adds a step and can impact its delicate profile.

The Human Equation: From Artisan to Automated System

Beyond the mechanism, the next critical choice is the level of automation. This isn't just about speed; it's about the role you want people to play in your process.

Semi-Automatic: Control and Flexibility

A semi-automatic machine requires an operator to place each container and activate the fill cycle, usually with a footswitch. It's a partnership between human and machine. This is the ideal starting point for artisanal producers and growing businesses that need to balance a smaller capital investment with the flexibility to handle diverse jar sizes and small batches.

Fully Automatic: Speed and Consistency

A fully automatic system is a true production line. Conveyors move containers through filling, capping, and labeling stations without human intervention. The initial cost is higher, but it delivers unmatched speed and repeatability for large-scale commercial apiaries. The focus shifts from an operator doing the work to an operator managing the system.

The Inescapable Laws of Honey

Choosing a machine means making trade-offs. Your decision must be guided by the unchangeable properties of your product and the realities of your business.

Viscosity: The Unseen Force

Honey's thickness is the single most important factor. It dictates everything. A thick, unheated honey will defeat a simple gravity filler, but it's exactly what robust piston and pump fillers are designed to handle. Fighting your honey's natural viscosity is a losing battle; the goal is to choose a technology that works in harmony with it.

The Trade-Off Matrix: Speed vs. Accuracy

Every beekeeper wants a machine that is fast, accurate, and cheap, but you can only ever optimize for two. A net weigh filler provides perfect accuracy but may fill slower than a rotary pump filler designed for sheer throughput. You must decide what costs more: a few extra seconds per jar, or a few extra grams of honey in every jar.

| Mechanism | Core Principle | Ideal Scenario | Key Trade-Off |

|---|---|---|---|

| Piston Filler | Positive Displacement (Volume) | High-viscosity honey; high accuracy | Slower cycle speeds on some models |

| Pump Filler | Timed Flow (Volume) | High-speed, continuous production | Accuracy can depend on pump consistency |

| Net Weigh Filler | Mass Measurement (Weight) | Highest accuracy needed; high-value product | Higher initial cost; potentially slower |

| Overflow Filler | Cosmetic Fill Height (Level) | Transparent containers; retail shelf appeal | Does not guarantee consistent volume/weight |

| Gravity Filler | Head Pressure (Level/Time) | Low-viscosity (heated) honey; startups | Low accuracy with thick or unheated honey |

Making a System, Not Just a Purchase

Your honey filling machine is not an isolated piece of equipment. It is the heart of your packaging operation, connecting your bulk supply to your finished product. The right choice integrates seamlessly, eliminating bottlenecks and protecting your bottom line. The wrong choice creates new problems and wastes your most valuable assets: your time and your honey.

As a wholesale-focused supplier to commercial apiaries, HONESTBEE provides robust beekeeping equipment designed for the rigors of high-volume production. We understand that choosing a filler is a systems-level decision. Whether you need a flexible semi-automatic piston filler for your premium batches or a fully integrated automatic line to meet distributor demand, we provide solutions that honor the quality of your product.

Understanding these principles is the first step; implementing the right system is the next. Contact Our Experts

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity