The Allure of the Makeshift Tool

In the quiet hum of an apiary, with a hundred hives to inspect before dusk, you realize your hive tool is missing. It’s back in the truck, or perhaps left at the last yard. The temptation is immediate and powerful: a large flathead screwdriver is right there in your pocket. It can pry things open. It will work.

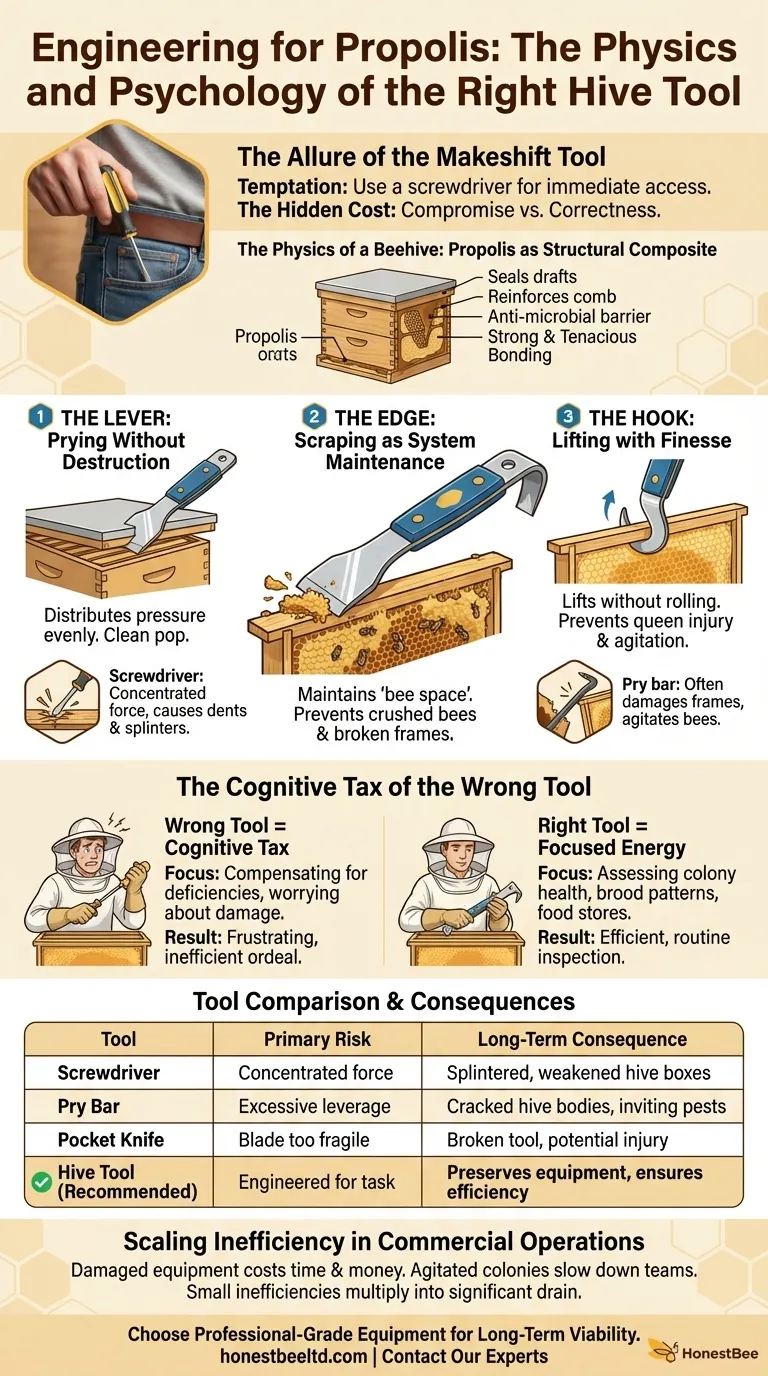

This is a familiar moment of compromise. We often favor the immediate solution over the correct one, underestimating the hidden costs of a decision that feels "good enough" in the moment. But in beekeeping, the gap between what works and what is right can determine the health of a colony and the longevity of your entire operation.

The Physics of a Beehive

To understand the tool, you must first respect the material it was designed to defeat: propolis.

Bees use this resinous mixture not as simple glue, but as a structural composite. They seal every draft, reinforce comb, and create an anti-microbial barrier. It is an engineering marvel of their own making. This substance is incredibly strong and tenacious, bonding wooden hive components into a single, solid unit.

The challenge isn't merely breaking a seal. It's doing so with controlled force, without sending a shockwave of agitation through the colony or inflicting irreparable damage on the hive itself.

A Study in Purpose-Built Design

A hive tool is not a brute-force instrument; it's a multi-tool engineered for a unique blend of power and finesse. Its design addresses the three distinct physical challenges a beekeeper faces in every single inspection.

The Lever: Prying Without Destruction

The wide, flat end of a hive tool acts as a lever, designed to distribute pressure evenly across the wood. When you break a propolis seal, the force is spread out, separating the hive bodies with a clean pop.

A screwdriver, by contrast, concentrates all that force onto a single, narrow point. The result is almost always a dent, a splinter, or a compression of the wood grain. Over time, these small damages accumulate, creating gaps that weaken the hive, expose it to weather, and offer entry points for pests like wax moths and hive beetles.

The Edge: Scraping as System Maintenance

Bees constantly build burr comb and deposit propolis where you don't want it. The sharpened, beveled edge of a hive tool is designed for scraping these surfaces clean.

This isn't just about tidiness; it's about maintaining the precise "bee space" that allows frames to be removed smoothly. Using a knife for this is ineffective, and a screwdriver is useless. Proper scraping ensures your equipment functions as intended, preventing crushed bees and broken frames during future inspections.

The Hook: Lifting with Finesse

The most elegant feature of many hive tools is the J-hook. Its purpose is singular and critical: to gently lift the first, tightly packed frame from a hive body.

By hooking it under the ear of the frame, you can lift straight up without rolling or jarring the comb. This single, graceful movement is nearly impossible with a makeshift tool. Attempting it with a pry bar or screwdriver often results in damaging the frame, killing the queen, and agitating thousands of guard bees.

The Cognitive Tax of the Wrong Tool

When you use the right tool, your mental energy is focused on the important task: assessing the colony's health. You're looking at brood patterns, checking for mites, and evaluating food stores.

When you use the wrong tool, your focus shifts. You are constantly compensating for the tool's deficiencies, worrying about splintering the wood, trying not to crush bees, and struggling to perform simple actions. This adds a significant cognitive tax to your work, turning a routine inspection into a frustrating and inefficient ordeal.

| Tool | Primary Risk | Long-Term Consequence |

|---|---|---|

| Screwdriver | Concentrated force | Splintered, weakened hive boxes |

| Pry Bar | Excessive, uncontrolled leverage | Cracked hive bodies, inviting pests |

| Pocket Knife | Blade is too fragile for prying | Broken tool, potential for injury |

| Hive Tool | Engineered for the task | Preserves equipment, ensures efficiency |

Scaling Inefficiency in Commercial Operations

For a hobbyist, a damaged hive box is an annoyance. For a commercial apiary, it's a cascading operational failure.

Damaged equipment must be repaired or replaced, costing time and money. Agitated colonies are less productive and more difficult to work with, slowing down your entire team. The small inefficiencies, when multiplied across hundreds or thousands of hives, become a significant drain on profitability and sustainability.

This is why professional-grade equipment isn't a luxury; it's a core component of a successful business. At HONESTBEE, we supply durable, intelligently designed beekeeping equipment specifically for commercial apiaries and distributors who understand that the right tool is an investment in protecting their assets—both the bees and the boxes they live in.

Choosing the right tool is about more than just opening a hive. It’s a reflection of your commitment to best practices and the long-term viability of your operation. To equip your teams for success, start with the fundamentals.

Visual Guide

Related Products

- Professional Stainless Steel Pry-Bar Hive Tool

- Professional Steel Pry-Bar Hive Tool with Painted Grip

- Multi-Function Hive Tool with Integrated Hammer for Beekeeping

- Professional Multi-Function Stainless Steel Hive Tool

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

Related Articles

- More Than Steel: How a Simple Hive Tool Dictates the Success of an Apiary

- The Essential Guide to Hive Tools in Modern Beekeeping

- The Physics of Propolis: Why Your Hive Tool Choice Defines Your Apiary's Workflow

- The Hive Tool as a Second Nature: Mastering the Micro-Movements of Beekeeping

- A Beekeeper's Oath: The Biosecurity and Ethics Engineered into a Bee Brush