Beekeeping success hinges on mastering small but critical tools—none more vital than your hive tool. This guide demystifies selection, maintenance, and strategic use to boost efficiency and hive health. Whether you're managing two hives or two hundred, the right techniques can save hours of labor and prevent costly damage.

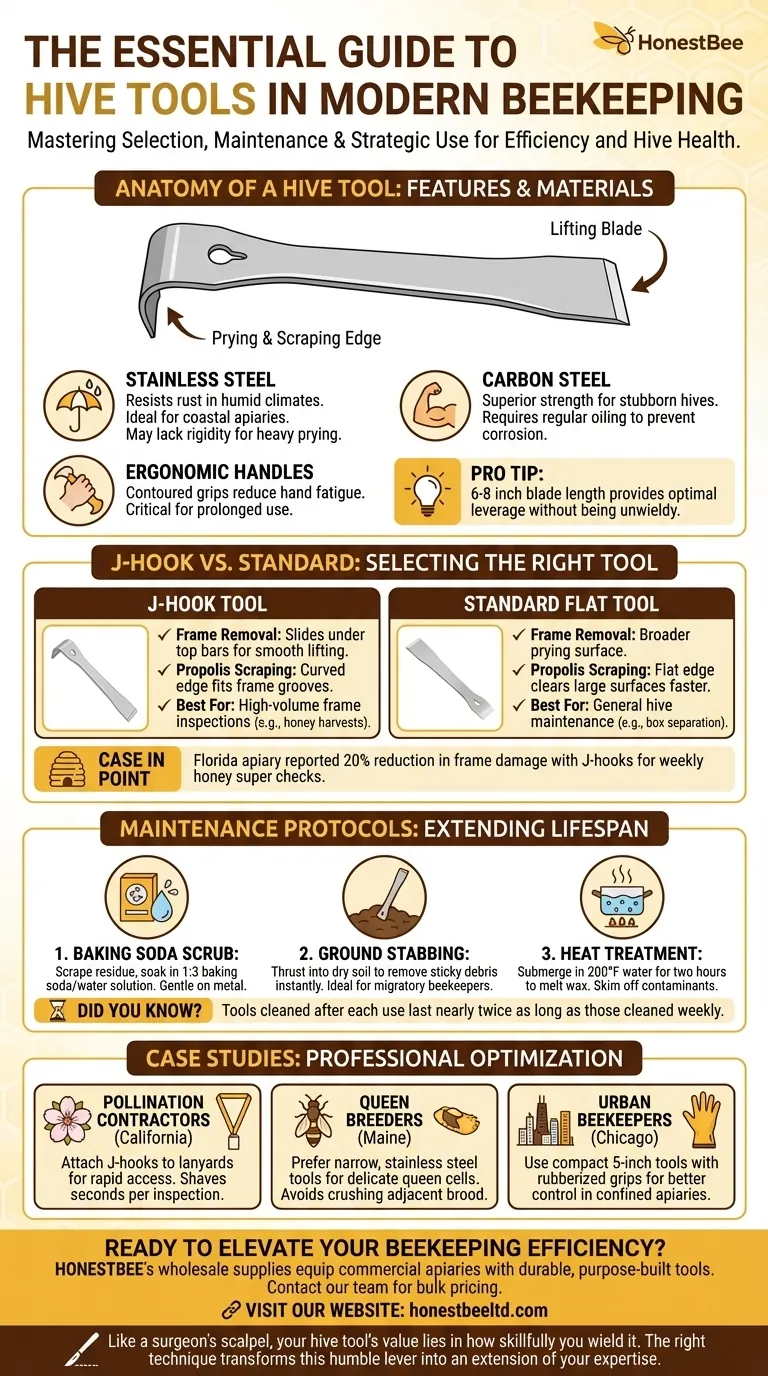

Anatomy of a Hive Tool: Key Features and Material Choices

Every hive tool serves three core functions: prying apart stuck hive components, scraping off propolis/wax buildup, and lifting frames. But material and design drastically impact performance:

-

Stainless Steel vs. Carbon Steel:

- Stainless resists rust in humid climates (ideal for coastal apiaries) but may lack the rigidity of carbon steel for heavy prying.

- Carbon steel offers superior strength for stubborn hives but requires regular oiling to prevent corrosion.

-

Ergonomic Handles: Look for contoured grips that reduce hand fatigue during prolonged use—critical for commercial beekeepers inspecting dozens of hives daily.

Pro Tip: Research shows tools with a 6–8-inch blade length provide optimal leverage without being unwieldy in tight hive spaces.

J-Hook vs. Standard: Selecting the Right Tool for Your Apiary

The debate between J-hook and standard flat tools isn’t about superiority—it’s about matching design to your workflow:

| Feature | J-Hook Tool | Standard Flat Tool |

|---|---|---|

| Frame Removal | Slides under top bars for smooth lifting with minimal disturbance | Requires more manual wiggling but offers broader prying surface |

| Propolis Scraping | Curved edge fits frame grooves | Flat edge clears large surfaces faster |

| Best For | High-volume frame inspections (e.g., honey harvests) | General hive maintenance (e.g., box separation) |

Case in Point: A Florida apiary reported a 20% reduction in frame damage after switching to J-hooks for their weekly honey super checks.

Maintenance Protocols: Extending Your Hive Tool’s Lifespan

Propolis and wax accumulation aren’t just messy—they harbor pathogens. Three proven cleaning methods:

-

Baking Soda Scrub:

- Scrape off major residue, then soak in a 1:3 baking soda/water solution.

- Gentle on metal and prevents abrasive scratching.

-

Ground Stabbing:

- Thrusting the tool into dry soil removes sticky debris instantly (a favorite among migratory beekeepers).

-

Heat Treatment:

- Submerge in 200°F water for two hours to melt wax—floating contaminants can then be skimmed off.

Did You Know? Tools cleaned after each use last nearly twice as long as those cleaned weekly.

Case Studies: How Professional Beekeepers Optimize Hive Tool Use

Pollination Contractors: Speed Meets Precision

California almond pollinators attach J-hooks to lanyards for rapid access during hive checks. This shaves seconds off each inspection—adding up to hours saved across thousands of hives.

Queen Breeders: The Delicate Balance

Maine queen producers prefer narrow, stainless steel tools to gently separate delicate queen cells without crushing adjacent brood.

Urban Beekeepers: Space-Saving Solutions

Chicago rooftop keepers use compact 5-inch tools with rubberized grips for better control in confined apiaries.

Ready to Elevate Your Beekeeping Efficiency?

HONESTBEE’s wholesale beekeeping supplies equip commercial apiaries with durable, purpose-built tools. From rust-resistant J-hooks to heavy-duty scrapers, our inventory helps professionals work smarter—not harder. Contact our team today for bulk pricing on tools designed to outlast the season.

Final Thought: Like a surgeon’s scalpel, your hive tool’s value lies not in its price tag, but in how skillfully you wield it. Whether separating honey-laden supers or rescuing a stuck inner cover, the right technique transforms this humble lever into an extension of your expertise.

Visual Guide

Related Products

- HONESTBEE Premium Italian Style Hive Tool with Hardwood Handle

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Stainless Steel Pry-Bar Hive Tool

- Multi-Function Plier-Style Frame Grip Hive Tool

Related Articles

- How to Relocate Beehives Safely: A Science-Backed Guide for Beekeepers

- More Than Steel: The Hive Tool as a Vector for Apiary Health

- Why We Lose Hive Tools: A Systems Approach to a Simple Problem

- The Typhoid Mary of the Apiary: Why Your Hive Tool is a Double-Edged Sword

- More Than Steel: How a Simple Hive Tool Dictates the Success of an Apiary