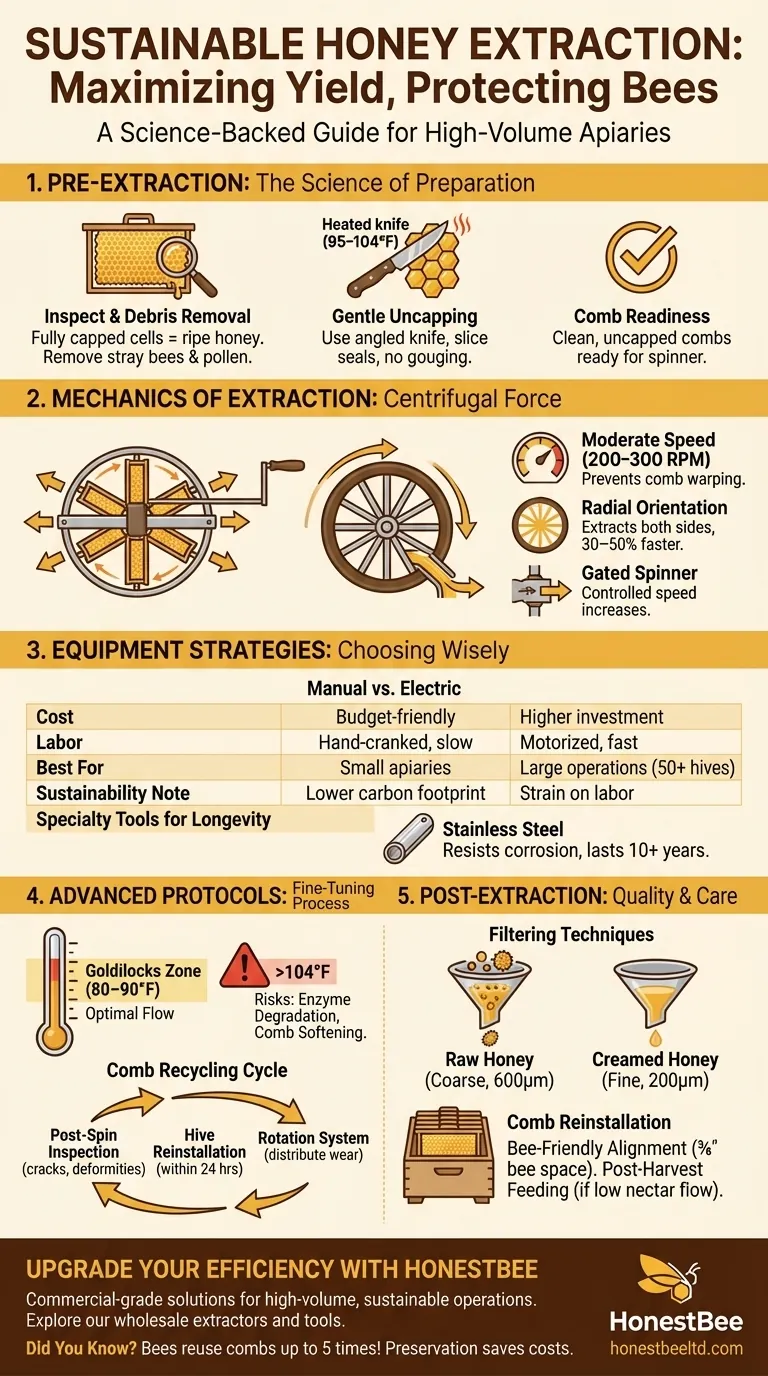

Modern beekeeping requires a delicate balance—harvesting honey efficiently while ensuring colonies remain healthy and combs stay intact. This guide reveals science-backed extraction techniques that protect your investment in bees and equipment.

The Science of Honey Extraction

Honey extraction isn’t just about removing liquid gold from combs; it’s a physics-driven process where precision determines yield and comb longevity.

Essential Pre-Extraction Comb Preparation

- Inspect Frame Cappings: Fully capped cells indicate ripe honey with low moisture content (ideal for extraction).

-

Gentle Uncapping: Use a heated knife (95–104°F) or scratcher to slice wax seals without gouging comb cells.

Pro Tip: Angled knives reduce drag, minimizing comb damage. - Debris Removal: Brush off stray bees or pollen to prevent contamination during spinning.

Centrifugal Force Mechanics Demystified

Centrifugal extractors work by creating outward force, pushing honey against frame walls until it drips out. Key factors:

- Speed: Moderate RPM (200–300) prevents comb warping.

- Frame Orientation: Radial designs (frames like wheel spokes) extract both sides simultaneously, saving 30–50% time vs. tangential models.

Equipment Selection Strategies

Choosing the right tools ensures efficiency and comb preservation—critical for commercial-scale beekeepers.

Manual vs. Electric Extractors Comparison

| Feature | Manual Extractors | Electric Extractors |

|---|---|---|

| Cost | Budget-friendly | Higher initial investment |

| Labor | Hand-cranked (slow) | Motorized (fast) |

| Best For | Small apiaries ( | Large operations (50+ hives) |

Sustainability Note: Manual models have a lower carbon footprint but may strain labor resources.

Specialty Tools for Comb Preservation

- Stainless Steel Extractors: Resist corrosion from honey’s acidity, lasting 10+ years.

- Gated Spinners: Allow controlled speed increases, reducing sudden force on combs.

Advanced Extraction Protocols

Fine-tuning your process preserves honey quality and comb reuse potential.

Temperature Control for Optimal Viscosity

Honey flows best at 80–90°F. Warmer temperatures (up to 104°F) thin honey for faster extraction but risk:

- Enzyme Degradation: Heating above 104°F breaks down beneficial enzymes like glucose oxidase.

- Comb Softening: Excessive heat weakens wax, leading to collapse during spinning.

Workaround: Warm extraction rooms gradually—never microwave combs.

Comb Recycling Best Practices

- Post-Spin Inspection: Check for cracks or deformities before reusing frames.

- Hive Reinstallation: Return combs within 24 hours so bees can repair minor damage.

- Rotation System: Alternate combs between hives to distribute wear evenly.

Post-Extraction Quality Assurance

Final steps determine marketability and hive health.

Filtering Techniques for Different Honey Types

- Raw Honey: Use coarse mesh (600 microns) to remove wax bits while retaining pollen.

- Creamed Honey: Fine filters (200 microns) ensure smooth texture.

Comb Reinstallation Standards

- Bee-Friendly Alignment: Rehang frames with bee space (⅜ inch) between combs to prevent crowding.

- Post-Harvest Feeding: Supplement with light syrup if nectar flow is low, aiding comb repair.

Ready to Upgrade Your Apiary’s Efficiency?

HONESTBEE’s commercial-grade extractors and uncapping tools help beekeepers like you harvest more honey sustainably—without compromising comb integrity. Explore our wholesale solutions designed for high-volume operations.

Did You Know? Bees reuse combs up to 5 times before rebuilding, making preservation a long-term cost saver.

By mastering these techniques, you’ll join a new wave of beekeepers proving that productivity and sustainability aren’t mutually exclusive—they’re the future of apiculture.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

Related Articles

- How to Choose the Right Honey Extractor Size: Balancing Capacity, Cost, and Efficiency

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- The Physics of a Perfect Harvest: Why the Honey Extractor Is a Marvel of Efficiency

- How Honey Extractors Revolutionize Sustainable Beekeeping