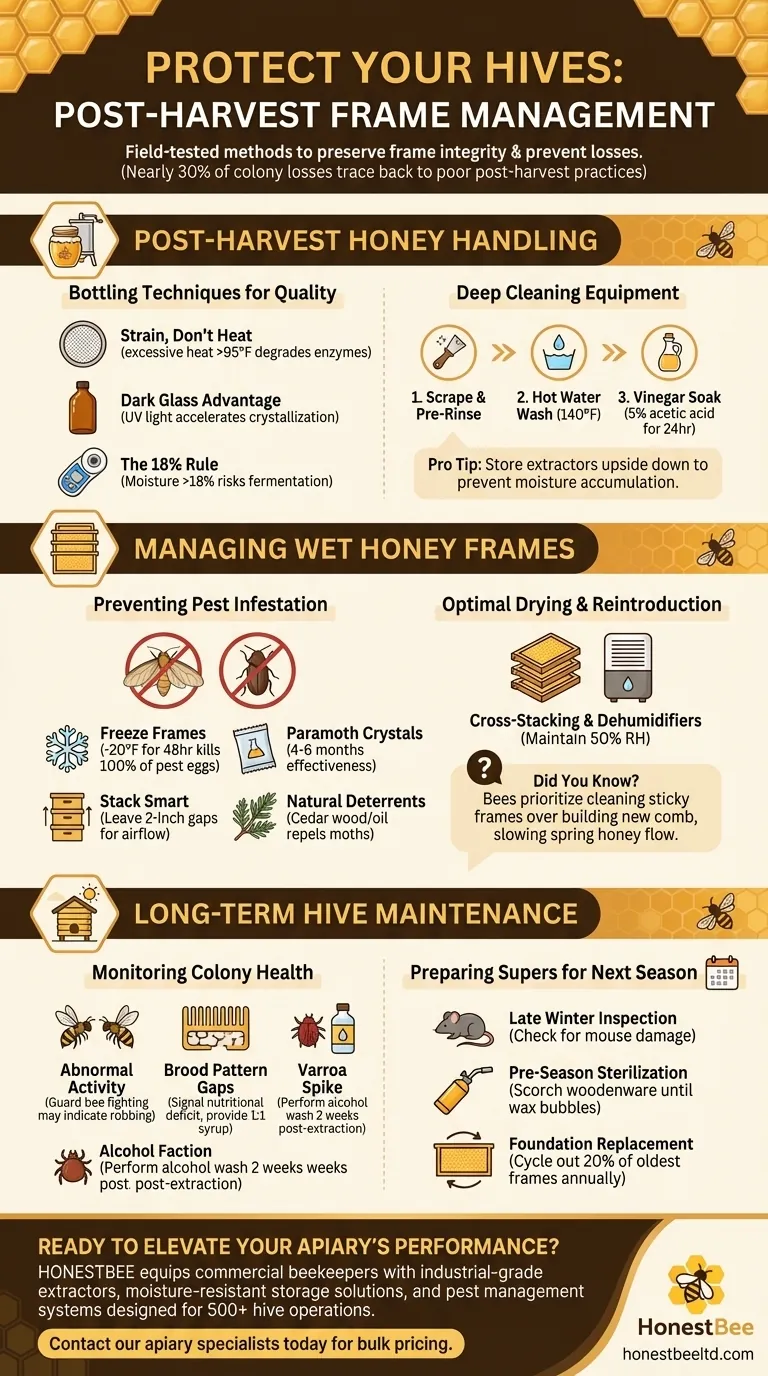

Every honey harvest marks a critical transition point for beekeepers—what happens next determines next season’s productivity. Research shows that nearly 30% of colony losses trace back to poor post-harvest practices, particularly pest infestations in stored equipment. This guide reveals field-tested methods to preserve frame integrity, prevent wax moth and small hive beetle damage, and set up hives for robust spring buildup.

Post-Harvest Honey Handling

Bottling Techniques to Preserve Quality

Honey’s shelf life depends on moisture control and contamination prevention. Use these steps to maintain flavor and texture:

- Strain, Don’t Heat: Excessive heat (above 95°F) degrades enzymes. Opt for 200-micron filters during extraction to remove debris while preserving pollen content.

- Dark Glass Advantage: UV light accelerates crystallization. Amber or cobalt bottles slow this process by blocking 90% of light waves.

- The 18% Rule: Honey with moisture levels exceeding 18% risks fermentation. Digital refractometers provide precise readings before bottling.

Deep Cleaning Extracting Equipment

Residual honey attracts pests and promotes mold. A three-phase cleaning protocol works best:

- Scrape & Pre-Rinse: Remove visible wax and propolis with a hive tool before water contact.

- Hot Water Wash: 140°F water dissolves stubborn residues without harming metal parts.

- Vinegar Soak: A 24-hour soak in 5% acetic acid solution eliminates bacterial biofilms in plastic components.

Pro Tip: Store cleaned extractors upside down to prevent moisture accumulation in valves.

Managing Wet Honey Frames

Preventing Pest Infestation During Storage

Wax moths and hive beetles seek out damp combs. Studies show freezing frames at -20°F for 48 hours kills 100% of pest eggs. For apiaries without freezer capacity:

- Paramoth Crystals: Place dichlorobenzene packets (follow label instructions) between stacked supers—effective for 4-6 months.

- Stack Smart: Leave 2-inch gaps between boxes for air circulation. Moisture-trapping tight stacks invite mold.

- Natural Deterrents: Cedar wood emits vapors that repel moths. Line storage room walls with cedar planks or use cedar oil sprays.

Optimal Drying and Reintroduction to Hives

Bees will repair slightly damp frames, but soggy combs collapse. Speed drying with:

- Cross-Stacking: Alternate frame directions in a well-ventilated shed to create airflow channels.

- Dehumidifiers: Maintain 50% relative humidity in storage areas—higher levels risk fermentation.

- Test Before Returning: Press a frame’s midrib. If honey seeps out, it needs 3-5 more drying days.

Did You Know? Bees prioritize cleaning sticky frames over building new comb, slowing spring honey flow.

Long-Term Hive Maintenance

Monitoring Colony Health Post-Extraction

Harvest stress can trigger robbing behavior or queen failure. Watch for:

- Abnormal Bee Activity: Guard bees fighting at the entrance may indicate robbing attempts. Reduce entrance sizes temporarily.

- Brood Pattern Gaps: Spotty brood post-harvest often signals nutritional deficit. Provide 1:1 sugar syrup if natural forage is scarce.

- Varroa Spike: Honey removal disrupts the hive’s balance. Perform an alcohol wash test 2 weeks after extraction.

Preparing Supers for Next Season

Properly stored supers yield 30% more honey in subsequent flows. The HONESTBEE Beekeeper’s Calendar recommends:

- Late Winter Inspection: Check for mouse damage or webbing in stored equipment.

- Pre-Season Sterilization: Before spring buildup, scorch woodenware with a propane torch until surface wax bubbles (1-2 seconds per spot).

- Foundation Replacement: Cycle out 20% of oldest frames annually to prevent pesticide buildup in wax.

Ready to Elevate Your Apiary’s Performance?

HONESTBEE equips commercial beekeepers with industrial-grade extractors, moisture-resistant storage solutions, and pest management systems designed for 500+ hive operations. Our wholesale program helps distributors stock proven tools that protect pollination contracts and honey yields. Contact our apiary specialists today for bulk pricing on essential equipment.

By implementing these protocols, beekeepers can turn post-harvest downtime into a strategic advantage—transforming routine maintenance into the foundation of next season’s success.

Visual Guide

Related Products

- Stainless Steel 9 Frame Hive Spacer Durable Precise for Commercial Beekeeping

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Professional In-Hive Frame Bee Feeder by HONESTBEE

- Professional Wooden Requeening Frame for Beekeeping

Related Articles

- The Beekeeper's Dilemma: Choosing Between Wooden Frame Ideals and Plastic Frame Efficiency

- How to Harvest Honey from Foundationless Frames Without Damaging Wax Combs

- How Wooden Frames Deliver Better Long-Term Value for Commercial Beekeepers

- Beyond the Scraper: The Invisible War on a Beehive Frame

- Wooden vs. Plastic Bee Hive Frames: Balancing Sustainability and Practicality