The Beekeeper's Dilemma

After a successful honey harvest, a beekeeper is left with a mountain of wax cappings. This is not waste; it is a second harvest, a valuable substance holding the faint aroma of honey and the golden light of the sun.

But this value is locked in a solid state. The immediate human impulse is to apply force to get it out—in this case, heat. And our bias is nearly always to apply more heat to get the job done faster.

With beeswax, this intuition is not just wrong; it's destructive.

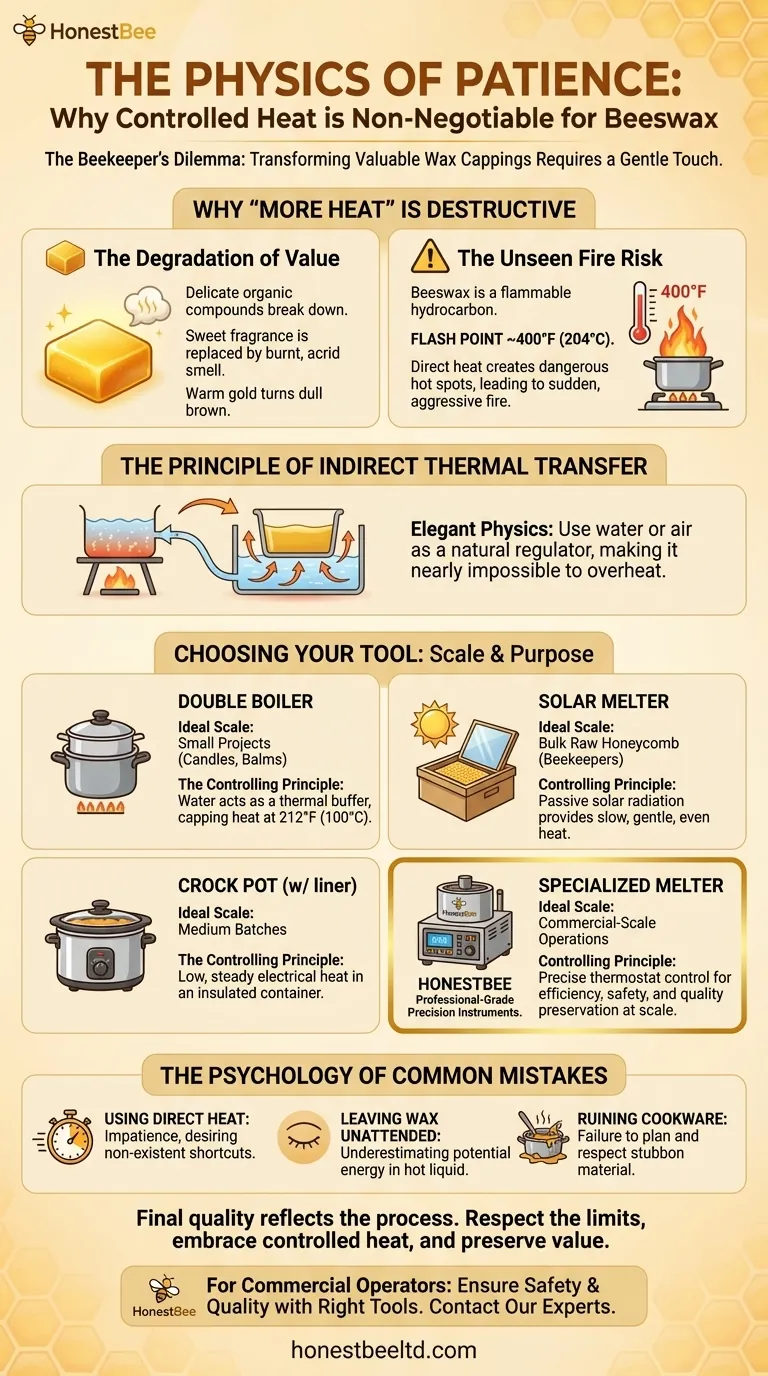

Why "More Heat" is the Wrong Answer

The process of melting beeswax is a test of patience. It’s a substance that rewards a gentle approach and punishes haste. Applying aggressive, direct heat is a fundamental misunderstanding of the material for two critical reasons.

The Degradation of Value

Beeswax is delicate. High temperatures scorch it, breaking down its complex organic compounds. The first thing to go is the subtle, sweet fragrance, replaced by a burnt, acrid smell.

Next, the color darkens from a warm gold to a dull, lifeless brown. The value of the wax—both aesthetic and monetary—is literally burned away. What was once a premium natural product becomes a damaged material.

The Unseen Fire Risk

The second reason is far more dangerous. Beeswax is a hydrocarbon; it is flammable. It has a flash point of around 400°F (204°C).

This isn't just a high number on a data sheet. It's a physical threshold. When you place a pot of wax directly on a stovetop, you create intense hot spots at the bottom, making it frighteningly easy to cross that threshold without warning. The result can be a sudden, aggressive fire.

The Principle of Indirect Thermal Transfer

The solution is not a complicated piece of technology but an elegant principle of physics: indirect heat.

Instead of applying energy directly to the wax, you use an intermediary—typically water or air—to transfer the heat gently and evenly. This intermediary acts as a natural regulator, making it almost impossible to overheat the wax.

The Gold Standard: The Double Boiler

This is the classic implementation of indirect heat. A pot of wax sits inside a larger pot of simmering water. The water cannot get hotter than its boiling point (212°F / 100°C), creating a perfect temperature ceiling. The heat is transferred gently, melting the wax without a hint of scorching.

Harnessing the Sun: The Solar Melter

For beekeepers processing raw honeycomb, the solar melter is a beautiful, passive system. It uses the sun's energy—a distant, perfectly regulated fusion reactor—to slowly melt wax away from impurities. It is the epitome of patience, relying on a warm day and time to do its work flawlessly.

Choosing Your Tool: A Matter of Scale and Purpose

The right method is dictated entirely by your objective. The constant is the principle of controlled heat; the variable is the scale of your operation.

| Method | Ideal Scale & Use Case | The Controlling Principle |

|---|---|---|

| Double Boiler | Small Projects (Candles, Balms) | Water acts as a thermal buffer, capping heat at 212°F. |

| Solar Melter | Bulk Raw Honeycomb (Beekeepers) | Slow, passive solar radiation provides gentle, even heat. |

| Crock Pot (with liner) | Medium Batches | Low, steady electrical heat in an insulated container. |

| Specialized Melter | Commercial-Scale Operations | Precise thermostat control for efficiency and safety. |

For artisans and hobbyists, a dedicated double boiler offers unparalleled safety and quality control. For apiaries clarifying mountains of raw cappings, a solar melter is a timelessly efficient tool.

But for commercial operations that need to process large volumes of rendered wax quickly and consistently, purpose-built equipment is the only logical choice. Professional-grade melters from HONESTBEE are not simply "heaters." They are precision instruments, engineered with thermostats that hold wax at the perfect temperature for hours, ensuring both efficiency and the preservation of quality at scale.

The Psychology of Common Mistakes

Most errors in handling beeswax are not failures of equipment, but failures of psychology.

- Using Direct Heat: Stems from impatience and a desire for a shortcut that doesn't exist.

- Leaving Wax Unattended: A lapse in focus, underestimating the potential energy stored in hot liquid wax.

- Ruining Cookware: A failure to plan, not respecting that wax is a stubborn material that demands its own dedicated tools.

The final quality of your beeswax is a direct reflection of the process used to render it. It is a physical record of your patience and your understanding of the material. By respecting its limits and embracing the elegant principle of controlled heat, you preserve its inherent value.

For commercial operators who understand that the right process requires the right tools, ensuring safety and quality is paramount. Contact Our Experts

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

Related Articles

- How to Melt Beeswax Safely: Science-Backed Protocols to Prevent Overheating and Fires

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- The Beekeeper's Paradox: Why Slow Heat Unlocks the True Value of Beeswax

- How Beekeepers Turn Wax Cappings From Waste to Profit

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks