Whether you're a beekeeper, candle maker, or cosmetic formulator, melting beeswax without damaging its natural properties requires precision. This guide reveals equipment-flexible techniques to maintain wax integrity across urban kitchens, off-grid locations, and bulk processing scenarios—backed by thermal science and real-world testing.

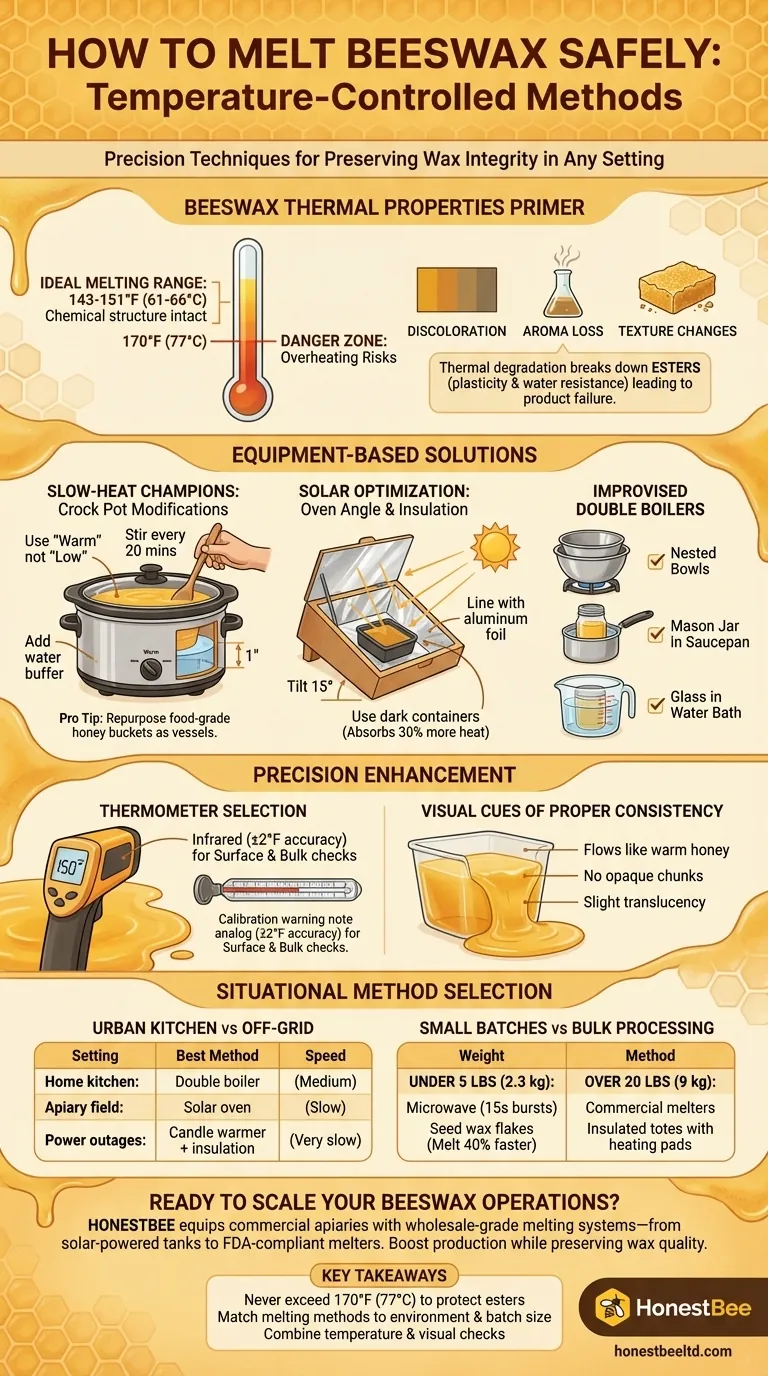

Beeswax Thermal Properties Primer

Flash Point vs Ideal Melting Range

Beeswax begins melting between 143-151°F (61-66°C), but its chemical structure stays intact below 170°F (77°C). Exceeding this threshold risks:

- Discoloration: Amber wax turning dull brown

- Aroma loss: Volatile compounds evaporate

- Texture changes: Brittle or grainy consistency

Risks of Thermal Degradation

Research shows overheating breaks down esters—the compounds giving beeswax its plasticity and water resistance. Have you noticed failed batches with poor adhesion in candles or uneven emulsification in balms? Thermal damage is often the culprit.

Equipment-Based Solutions

Slow-Heat Champions: Crock Pot Modifications

Low-temperature crock pots (or slow cookers) maintain ideal 150-160°F (65-71°C) ranges when:

- Using the "warm" setting instead of "low"

- Adding 1" water buffer beneath wax containers

- Stirring every 20 minutes to distribute heat

Pro Tip: HONESTBEE's beekeeping clients repurpose old honey buckets as food-grade melting vessels.

Solar Optimization: Oven Angle & Insulation Tips

For solar melting (ideal in apiaries):

- Tilt solar ovens 15° toward the sun

- Line with aluminum foil to reflect infrared rays

- Use dark-colored containers to absorb 30% more heat

Improvised Double Boilers: Alternative Containers

No dedicated double boiler? Try:

✔ Two nested stainless steel bowls

✔ A mason jar in a saucepan

✔ Glass measuring cups in water baths

Precision Enhancement

Thermometer Selection for Wax Crafting

Infrared thermometers (±2°F accuracy) work best for:

- Surface temperature checks

- Bulk wax monitoring

Analog candy thermometers suit small batches but require frequent calibration.

Visual Cues of Proper Consistency

Perfectly melted wax should:

- Flow like warm honey

- Leave no opaque chunks

- Show slight translucency

Situational Method Selection

Urban Kitchen vs Off-Grid Scenarios

| Setting | Best Method | Speed |

|---|---|---|

| Home kitchen | Double boiler | Medium |

| Apiary field | Solar oven | Slow |

| Power outages | Candle warmer + insulation | Very slow |

Small Batches vs Bulk Processing

For under 5 lbs (2.3 kg):

- Microwave in 15-second bursts (stirring between)

- Seed wax flakes melt 40% faster than blocks

For 20+ lbs (9 kg):

- Commercial-grade wax melters

- Insulated totes with heating pads

Ready to Scale Your Beeswax Operations?

HONESTBEE equips commercial apiaries and distributors with wholesale-grade melting systems—from solar-powered tanks to FDA-compliant melters. Discover how our beekeeping solutions preserve wax quality while boosting production efficiency.

Key Takeaways

- Never exceed 170°F (77°C) to protect wax esters

- Match melting methods to your environment and batch size

- Combine temperature monitoring with visual checks for reliability

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

Related Articles

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- The Physics of Patience: Why Controlled Heat is Non-Negotiable for Beeswax

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks

- How to Melt Beeswax Safely: Science-Backed Protocols to Prevent Overheating and Fires

- How to Transform Old Beeswax into Profitable and Sustainable Products