It's Not a Deadline, It's a Diagnostic

Every beekeeper asks it: "How long until my bees draw out the comb?"

Under perfect conditions, a powerful colony can draw and fill a single frame in a week. But "perfect conditions" are a statistical rarity. The truth is, the question itself is flawed.

The speed of comb construction isn't a schedule to be met. It is a direct, unfiltered readout of the hive's internal economy. Viewing it this way transforms you from a manager waiting on a deadline to a strategist reading the market.

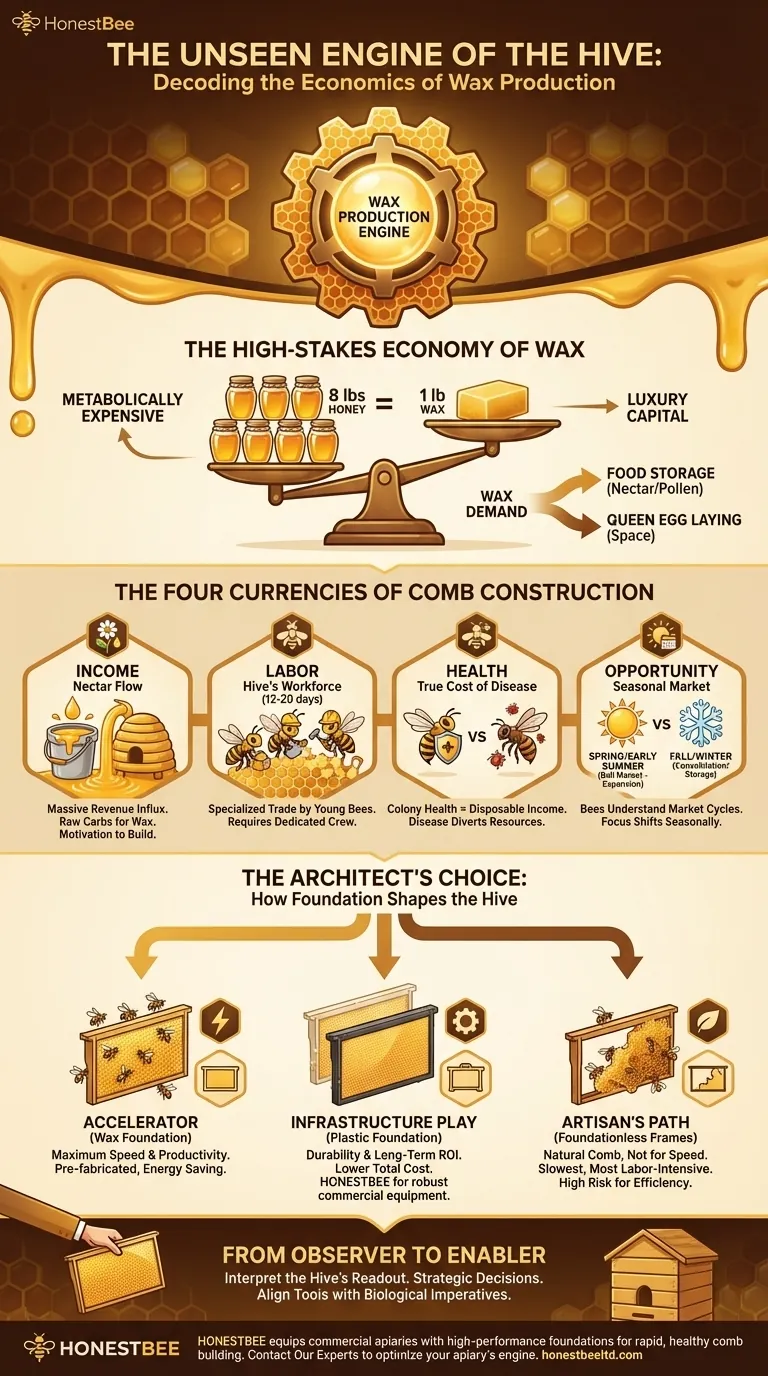

The High-Stakes Economy of Wax

Bees don't build wax for leisure. It is one of the most metabolically expensive tasks in the hive, a strategic decision driven by brutal necessity.

To produce a single pound of wax, a colony must consume roughly eight pounds of honey. This staggering 8:1 ratio means wax is a luxury good, a capital investment that is never made without a clear and pressing return.

The demand is non-negotiable: bees need space to store food (nectar and pollen) and space for the queen to lay eggs. Without this infrastructure, the colony stagnates and dies. This is the engine driving production—not a timeline, but a desperate need for growth.

The Four Currencies of Comb Construction

A hive's ability to "spend" honey on wax production depends on its access to four essential forms of capital. A deficiency in any one of them halts the entire operation.

1. Income: The Nectar Flow

This is the single most critical factor. A strong nectar flow is a massive influx of revenue. It provides the raw carbohydrates for wax synthesis and the urgent motivation to build storage. Without incoming resources, bees shift into conservation mode. You wouldn't build an extension on your house after losing your job; a hive won't build wax during a nectar dearth.

2. Labor: The Hive's Workforce

Wax production is a specialized trade performed by young worker bees, typically between 12 and 20 days old. A hive with a booming population of young, healthy bees has the dedicated construction crew needed for rapid expansion. A small or aging colony simply lacks the specialized labor force, regardless of the nectar flow.

3. Health: The True Cost of Disease

Colony health is its disposable income. Diseases, especially a high Varroa mite load, act as a crippling tax on the hive's resources. Energy that should go toward foraging and building is diverted to fighting off parasites and raising replacement bees. A healthy hive invests its capital in growth; a sick hive spends it all on survival.

4. Opportunity: The Seasonal Market

Bees are master economists of time. They instinctively understand market cycles. Spring and early summer are a bull market—resources are abundant, and the mandate is aggressive expansion. As the season wanes into fall, the market shifts. The focus turns to consolidating existing assets and storing resources for the long winter. Building new wax in October is a poor investment, and the bees know it.

The Architect's Choice: How Foundation Shapes the Hive

As the beekeeper, your choice of equipment is a direct intervention in the hive's economy. You aren't just providing a box; you are providing an economic incentive and a strategic blueprint.

The Accelerator: Wax Foundation

- For Maximum Speed and Productivity

Providing frames with pure beeswax foundation is like giving your construction crew pre-fabricated walls. The bees readily accept it, saving enormous energy and time. This is the preferred method for commercial apiaries focused on maximizing honey production or executing rapid splits. It removes a major bottleneck in their production cycle.

The Infrastructure Play: Plastic Foundation

- For Durability and Long-Term ROI

Plastic foundation is a long-term capital investment. Its durability and reusability offer a lower total cost of ownership over many seasons—a critical metric for any large-scale operation. While some colonies may take slightly longer to accept it, a light coating of wax can dramatically increase adoption rates.

For commercial apiaries and distributors, sourcing high-quality, uniformly coated plastic foundation is key to ensuring consistent performance across hundreds or thousands of hives. This is where HONESTBEE excels, providing robust equipment designed for the rigors of commercial use.

The Artisan's Path: Foundationless Frames

- For Natural Comb, Not for Speed

Foundationless beekeeping allows bees to build comb to their own natural specifications. It is a valid approach for a specific style of beekeeping, but it is by far the slowest and most labor-intensive for the bees. It requires them to architect and build the entire structure from scratch, carrying higher risks of structural problems like cross comb. For an operation where efficiency is paramount, this is not a viable path.

From Observer to Enabler

Stop asking "how long" and start asking "what is the hive telling me?"

A slow build-out isn't a sign of lazy bees; it's a data point. It may indicate a poor nectar flow, an underlying health issue, or a demographic imbalance in your workforce.

By understanding the hive's internal economy, you can make strategic decisions. You can provide a simulated nectar flow with syrup to jumpstart a new colony, or you can supply them with the highest quality foundation to reduce their energy expenditure and accelerate their core mission. Your role is to provide the tools that align with their biological imperatives.

At HONESTBEE, we equip commercial apiaries and distributors with the high-performance foundations and durable frames needed to turn a hive’s potential into tangible results. Our wholesale-focused model ensures you have the right equipment to support rapid, healthy comb building at scale. To optimize your apiary's economic engine, Contact Our Experts.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Related Articles

- The Beekeeper's Paradox: Why Slow Heat Unlocks the True Value of Beeswax

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- How Beekeepers Turn Wax Cappings From Waste to Profit