A Single Warped Cell

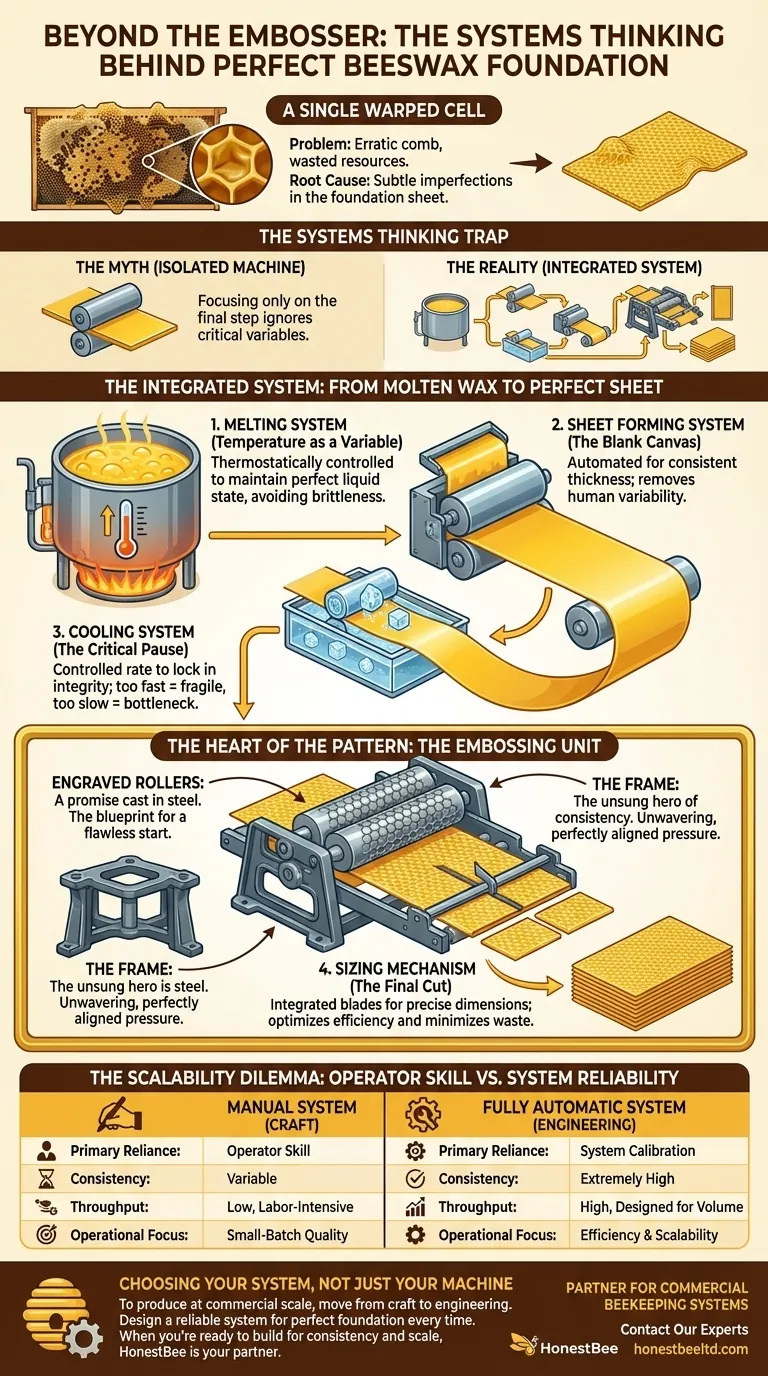

Imagine a commercial apiary manager pulling a frame from a hive. The colony isn't building it out as expected. The bees are constructing erratic burr comb, wasting energy and resources. The problem traces back to a subtle imperfection: a foundation sheet that was slightly too thin in one spot, slightly warped from inconsistent cooling.

This isn't a failure of the bees. It's a failure of the system that produced their guide.

We tend to think of a beeswax foundation machine as the single, satisfying moment where rollers press a hexagonal pattern into a sheet of wax. But this is a psychological trap. The machine isn't a machine; it's a process. And focusing only on the final step ignores the cascade of variables that determine success or failure.

True quality at a commercial scale comes from seeing it not as a tool, but as an integrated system.

The Heart of the Pattern: The Embossing Unit

The embossing rollers are where the magic happens, but they can't perform that magic alone. They are the lead actors in a play that relies on a critically important stage.

The Engraved Rollers: A Promise in Steel

The embossing rollers are a promise cast in metal. Their precision-engraved surfaces hold the negative of a perfect honeycomb, a blueprint for the colony. As the smooth wax sheet passes between them, they impart this blueprint, offering the bees a mathematically perfect start. Their engineering defines the potential for a flawless foundation.

The Frame: The Unsung Hero of Consistency

But that potential is only realized through pressure—unwavering, perfectly aligned pressure. This is the job of the cast iron frame. It is the stoic, silent partner that holds the rollers in exact alignment, ensuring the pattern is pressed with uniform depth from the first sheet of the day to the thousandth. Without this rigidity, the promise of the rollers is broken.

The Supporting Cast: From Molten Wax to Perfect Sheet

The embossing unit is the star, but its performance is dictated entirely by the quality of the material it's given. The supporting systems are what transform raw beeswax into the perfect blank canvas.

Temperature as a Variable: The Melting System

Beeswax is temperamental. Too hot, it becomes brittle when it cools. Not hot enough, it flows poorly. A thermostatically controlled melting vat isn't a convenience; it's a control system for a critical variable. It ensures the wax is held in that perfect liquid state, ready to be formed without introducing flaws that will haunt the final product.

The Blank Canvas: The Sheet Forming System

This is the first moment of creation. In a manual setup, this is the art of using dipping boards to pull a sheet of just the right thickness from a vat. It’s a craft defined by human skill.

In an automated system, this art is replaced by science. Liquid wax flows onto rollers or belts to form a continuous, perfectly uniform ribbon. The goal is the same: create a flawless blank canvas. The difference is removing human variability from the equation.

The Critical Pause: The Cooling System

Before it can be embossed, the liquid wax sheet must solidify. This isn't a passive wait; it's a controlled process. A water bath or cooled rollers must remove heat at the right rate. Too fast, and the wax becomes fragile. Too slow, and the production line grinds to a halt. Cooling is the critical pause that locks in the sheet's integrity.

The Final Cut: The Sizing Mechanism

The final step is cutting the foundation to size. For a small operation, a pizza cutter and a steady hand suffice. For a commercial producer, integrated blades that automatically slice the embossed ribbon to precise dimensions are essential. This is the point where the system optimizes for efficiency and minimizes waste.

The Scalability Dilemma: Operator Skill vs. System Reliability

The choice between a manual and automatic system isn't just about cost; it’s a fundamental choice about where you place your trust. Do you build your business on the variable artistry of human skill, or on the consistent, repeatable precision of a machine?

| Factor | Manual System | Fully Automatic System |

|---|---|---|

| Primary Reliance | Operator Skill & Experience | System Calibration & Reliability |

| Consistency | Variable; depends on the person | Extremely High; uniform output |

| Throughput | Low; labor-intensive | High; designed for volume |

| Capital Outlay | Low | Significant |

| Operational Focus | Craft and small-batch quality | Efficiency and scalable production |

For the hobbyist, a manual system is a beautiful way to be self-sufficient. For a commercial apiary or a beekeeping equipment distributor, relying on operator skill becomes the single biggest bottleneck to growth and quality control.

Choosing Your System, Not Just Your Machine

To produce foundation at a commercial scale is to move from craft to engineering. It requires seeing beyond the individual components and designing a complete, reliable production system where every step is controlled.

This is the shift in thinking required to supply hundreds of hives or thousands of customers. It’s about building a process that delivers a perfect foundation every time, because you know that even a single warped cell, magnified across an entire operation, is a tax on productivity.

When you're ready to build a system that guarantees consistency and scale, you need a partner who understands the demands of high-volume production. HONESTBEE specializes in supplying robust, wholesale-focused equipment that forms the backbone of efficient beekeeping operations. We provide the systems that turn your raw beeswax into a reliable, profitable asset.

Let us help you design the right production system for your goals. Contact Our Experts

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

Related Articles

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- Why Your Milled Beeswax Foundations Warp—And How to Fix It for Good

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- How Beeswax Foundation Machines Transform Beekeeping Efficiency