It’s a familiar scene in the lab: you’ve spent the afternoon hunched over your equipment, carefully selecting your best drones and meticulously performing each step of the instrumental insemination process. Yet, at the end of the day, you have only a handful of successfully inseminated queens to show for it. The rest are a frustrating write-off, representing hours of lost labor and a major setback for your breeding program. You're left wondering, "What am I doing wrong?"

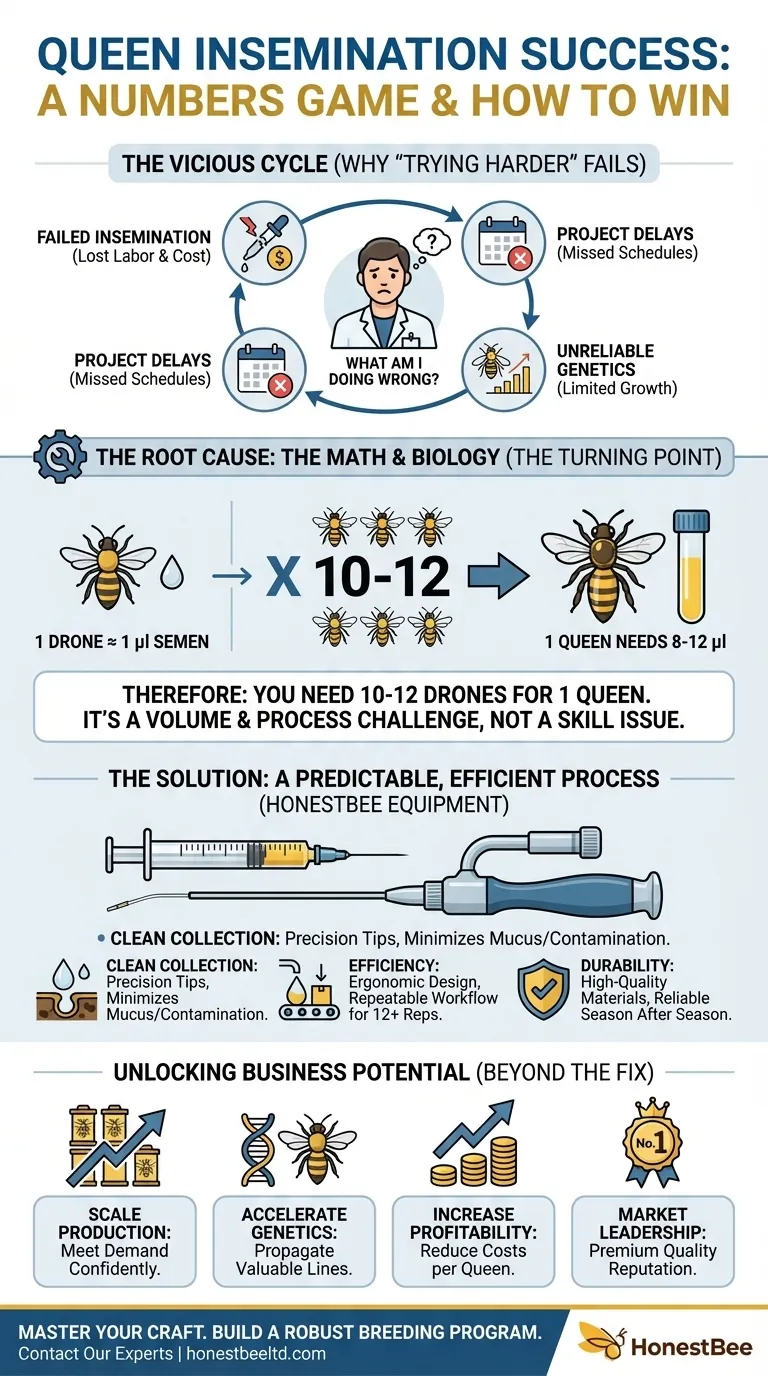

The Vicious Cycle: Why "Trying Harder" Doesn't Work

If this scenario feels personal, you're not alone. For commercial apiaries and breeders, inconsistent results from instrumental insemination are a chronic and costly problem. When faced with low success rates, the common reaction is to focus on refining one's personal technique.

Maybe you try to be more steady-handed. Perhaps you blame a "bad batch" of drones and hope the next group is better. You might even invest in a different style of insemination tip, hoping a small change will bring a breakthrough.

While these efforts are understandable, they rarely solve the underlying issue. The frustrating cycle continues, leading to significant business consequences:

- Project Delays: Your queen rearing schedule falls behind, creating a domino effect that impacts when your nucs and production colonies are ready.

- Cost Overruns: Every failed insemination is wasted labor. A process that should be a predictable part of your operation becomes a major cost center.

- Unreliable Genetics: You can't reliably scale the production of your most valuable genetic lines, limiting your ability to improve stock and grow your business.

This isn't just a technical challenge; it's a direct threat to your profitability and reputation.

The Root of the Problem: It’s Not Your Skill, It’s the Math

Here is the turning point. The struggle with instrumental insemination isn't primarily a failure of skill; it's a misunderstanding of the fundamental biology at play.

The core, unchangeable fact is this: a single, mature honey bee drone provides only about 1 microliter (µl) of semen.

A queen, however, requires 8 to 12 µl of semen for a successful insemination that fills her spermatheca and ensures a long, productive life.

The math is simple and unforgiving: you must successfully collect clean, viable semen from 10 to 12 individual drones to inseminate just one queen.

This single insight changes everything. It reveals why focusing on "perfecting" the collection from one drone is a losing strategy. The real challenge isn't performing a single, perfect action. It's executing a good, clean action a dozen times in a row, efficiently and without error, for every single queen you produce.

The common "solutions" fail because they ignore this reality:

- Trying to get more from one drone is biologically impossible.

- Hoping for a "better batch" of drones misses the point that you need a consistently large supply of mature drones to play the numbers game effectively.

- Focusing only on hand-steadiness is useless if your equipment is prone to clogging with mucus or is cumbersome to use, slowing you down and ruining samples.

The true bottleneck is the process. Success hinges on having a system that makes this high-volume, repetitive task as predictable and error-proof as possible.

The Solution: Turning a Numbers Game into a Predictable Process

To master this numbers game, you don't need magic hands. You need a system and tools designed for the reality of the task—tools that enable efficiency, minimize contamination, and maximize success across dozens of repetitions.

This is precisely why HONESTBEE provides professional-grade instrumental insemination equipment to commercial apiaries and distributors. Our systems are not designed for a single, flawless operation in a vacuum. They are engineered with the deep understanding that you need to perform this delicate task repeatedly, quickly, and cleanly to run a profitable business.

Here’s how our equipment directly addresses the root cause of failure:

- Engineered for Clean Collection: Our insemination tips and syringes are designed for maximum precision, helping you easily separate the valuable semen from the mucus that can clog tips and ruin inseminations. This drastically reduces sample contamination, one of the most common failure points.

- Designed for Efficiency: From ergonomic drone holders to smoothly operating manipulators, every component is built to reduce handling time and fatigue. This allows a skilled technician to move from one drone to the next with a consistent, repeatable workflow, turning a dozen individual collections into one fluid process.

- Built for Durability: In a commercial setting, equipment must withstand constant use. Our wholesale supplies are made from high-quality materials, ensuring your investment remains reliable season after season, eliminating equipment failure as a variable in your success.

Our tools are not a magic bullet. They are the logical answer to the biological equation—the right equipment to make the math work in your favor.

Beyond the Fix: What Reliable Insemination Unlocks for Your Business

When you solve the insemination bottleneck, you do more than just fix a technical problem. You transform the strategic potential of your entire operation. With a predictable and scalable queen insemination process, you can now:

- Confidently Scale Queen Production: Meet seasonal demand on time, every time, and expand your business by producing more high-quality queens.

- Accelerate Genetic Improvement: Systematically propagate your most valuable lines—those with high honey production, mite resistance, or gentle temperaments—with a high degree of confidence.

- Increase Profitability: Drastically reduce labor costs per queen and eliminate the financial drag of failed attempts.

- Become a Market Leader: Offer your customers exceptionally well-inseminated, reliably-mated queens, building a reputation for quality that commands a premium price.

You can finally shift your focus from the frustrating question of "Will this work?" to the strategic question of "Which genetic lines will drive my business forward?"

Solving this fundamental challenge isn't just about making more queens; it's about building a more resilient, predictable, and profitable beekeeping enterprise. If you're ready to move past the frustration and equip your operation for scalable success, our team is here to help. We specialize in supplying commercial apiaries and distributors with the tools they need to master their craft. Contact Our Experts to discuss the specific challenges in your apiary and build a more robust breeding program.

Visual Guide

Related Products

- Nicot Queen Rearing Kit for Beekeeping and Grafting in Nicot System

- Jenter Queen Rearing Kit Complete Set for Bee Breeding

- No Grafting Queen Rearing Kit: System for Royal Jelly Production and Queen Rearing

- Retractable Chinese Queen Rearing Grafting Tools Equipment

- Brown Nicot Queen Cell Cups for Breeding Queen Bees Beekeeping

Related Articles

- How to Rear Mite-Resistant Queen Bees: A Beekeeper’s Step-by-Step Guide

- Bee Space: The Unseen Law Governing a Productive Hive

- How Beekeepers Can Maximize Queen-Rearing Success with the JZBZ System

- Beyond the Bee Box: Why Your First Apiary Investment Determines Your Success

- The Comprehensive Benefits of Beekeeping