Yes, you can absolutely make candles using 100% pure beeswax. In fact, pure beeswax candles are one of the oldest and most revered types of candles in history. They burn brighter, cleaner, and longer than many other waxes, but their success hinges on understanding the unique properties of beeswax, particularly its high melting point and the absolute need for it to be clean.

The key to success with pure beeswax candles is not in the possibility, but in the execution. You must use impeccably clean wax to prevent wick clogging and carefully manage its higher burn temperature to ensure safety and performance, especially when using glass containers.

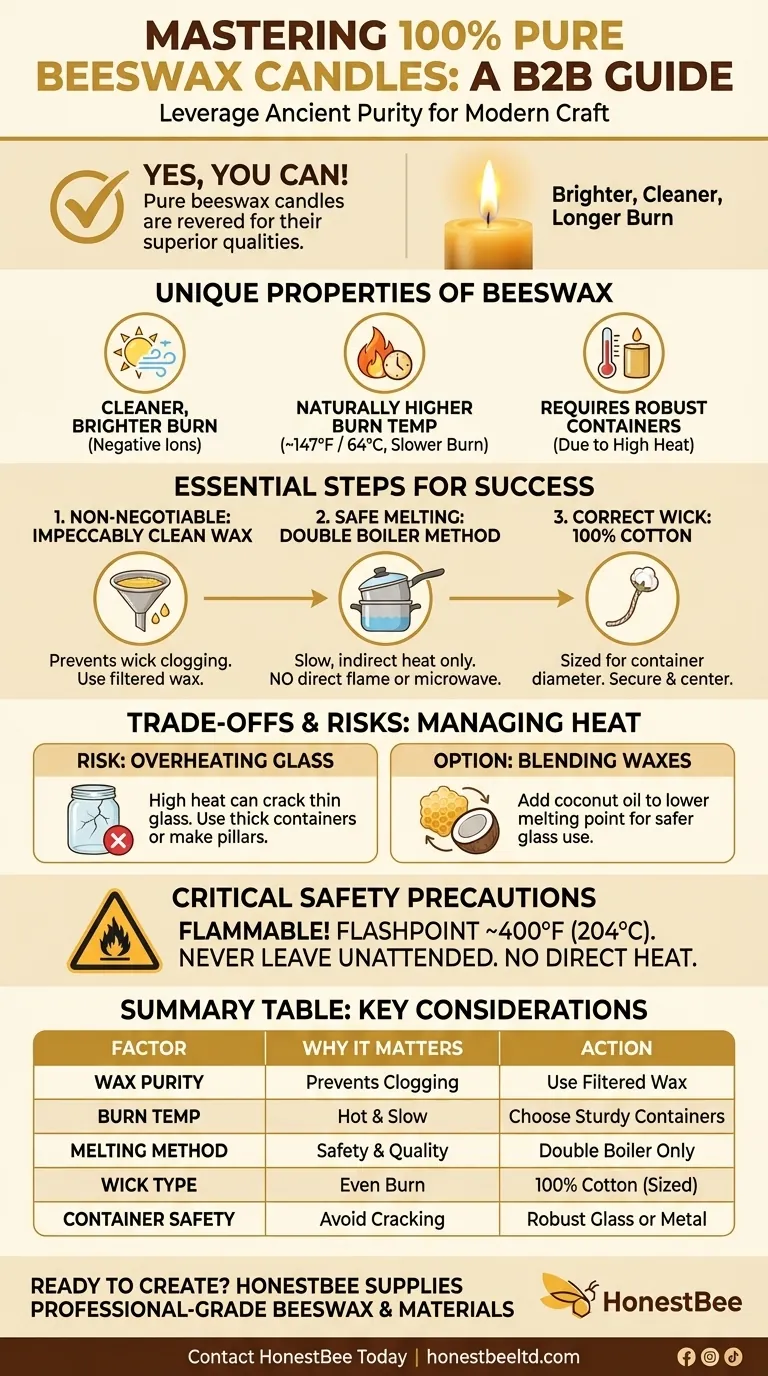

The Unique Properties of Beeswax

To work with pure beeswax, you must first appreciate what makes it different from other waxes like soy or paraffin.

A Cleaner, Brighter Burn

Beeswax is prized for its clean, smoke-free burn. It produces a vibrant, warm-toned light that is often described as being similar to sunlight.

Many people also believe that burning pure beeswax can help purify the air by releasing negative ions, which can neutralize airborne pollutants. This makes them an excellent choice for individuals with allergies or asthma.

A Naturally Higher Burn Temperature

Beeswax has a higher melting point (around 147°F or 64°C) than many other candle waxes.

This property means it burns more slowly and for a longer duration. However, it also means it burns hotter, which has important implications for your container choice.

Essential Steps for Pure Beeswax Candles

The process is straightforward, but success is found in the details. Overlooking these fundamentals is the most common source of problems.

Why Clean Wax is Non-Negotiable

Your beeswax must be exceptionally clean. Any residual honey, pollen, or other debris will be drawn up into the wick as the candle burns.

This debris will clog the cotton wick, preventing it from drawing fuel (melted wax) and causing the flame to sputter, shrink, or extinguish itself. Commercially prepared beeswax is typically filtered and ready to use.

The Double Boiler Method

The only safe way to melt beeswax is with slow, indirect heat. A double boiler provides this gentle, steady heating.

You can easily create one by placing your wax in a heat-resistant bowl or pouring pot and setting it over a saucepan filled with a few inches of simmering water.

Choosing the Right Wick

For pure beeswax, a 100% cotton wick is essential. The size of the wick must be appropriate for the diameter of your candle to ensure an even melt pool.

Once your wax is melted and you're ready to pour, you can secure the wick to the bottom of your container with a bit of hot glue or a wick sticker. A pencil or clothespin laid across the container's opening is perfect for keeping the wick centered and taut while the wax cools.

Understanding the Trade-offs and Risks

Working with pure beeswax requires an awareness of its powerful heat output and flammability.

The Risk of Overheating Containers

Because beeswax burns hotter, it can cause small or thin-walled glass containers to overheat and potentially crack. This is a significant safety hazard.

If you intend to make a 100% pure beeswax candle, it is safer to use a wider, more robust glass container, a metal tin, or to make freestanding pillar candles that don't require a container at all.

The Option of Blending Waxes

To mitigate the high heat, many candle makers blend beeswax with a softer oil, such as coconut oil.

Adding a small amount of coconut oil lowers the overall melting point of the wax. This creates a slightly softer candle that burns a little less intensely, making it safer for use in a wider variety of glass jars.

Critical Safety Precautions

Beeswax is flammable and will catch fire if it reaches its flashpoint of around 400°F (204°C). Never melt beeswax in a microwave or over direct heat.

Always supervise the melting process and never leave a burning candle unattended. If you spill any melted wax, clean it up immediately to prevent accidents.

Making the Right Choice for Your Goal

Your final approach depends on what you want to achieve with your candle.

- If your primary focus is a 100% pure beeswax candle: Choose a thick, sturdy container designed for candles or make a pillar candle to avoid the risk of overheating glass.

- If your primary focus is using decorative glass jars: Blend your beeswax with a small amount of coconut oil to lower the burn temperature and ensure the container's safety.

- If your primary focus is safety and a successful first attempt: Always use the double boiler method, ensure your wax is perfectly clean, and never walk away from melting wax or a burning candle.

By understanding these core principles, you are fully equipped to create beautiful, natural candles that burn cleanly and safely.

Summary Table:

| Key Consideration | Why It Matters for Pure Beeswax Candles |

|---|---|

| Wax Purity | Must be impeccably clean to prevent wick clogging from debris. |

| Burn Temperature | Burns hotter and slower than other waxes; requires careful container selection. |

| Melting Method | Requires a double boiler for safe, indirect heating to prevent fire risk. |

| Wick Type | A 100% cotton wick of the correct size is essential for an even burn. |

| Container Safety | Thin glass can crack from the high heat; sturdy glass or metal is safer. |

Ready to create your own pure beeswax candles? HONESTBEE supplies beekeepers and commercial apiaries with high-quality, filtered beeswax and professional-grade candle-making supplies through our wholesale operations. Ensure your projects are a success with our pure materials. Contact HONESTBEE today to discuss your needs and discover how we can support your beekeeping or product creation goals.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What equipment is required for manufacturing beeswax candles? Professional Tools for High-Quality Production

- What is the significance of using beeswax casting molds? Transform Your Refined Wax into a Professional Commodity

- What is the first tip for pouring beeswax into a silicone mold? Ensure a Perfect Release

- How is cost optimization achieved during the professional refining process of beeswax candles? Expert Strategies Revealed

- What is the benefit of using a wax blend for beeswax candles? Achieve Safer, Smoother-Burning Container Candles

- What primary raw materials from the honey harvesting process are used for manufacturing beeswax candles?

- What are the essential tools and materials for beeswax candle manufacturing? Start Your Commercial Production Today

- What equipment and tools are needed for making beeswax candles? Master the Melt for Safe, Quality Results