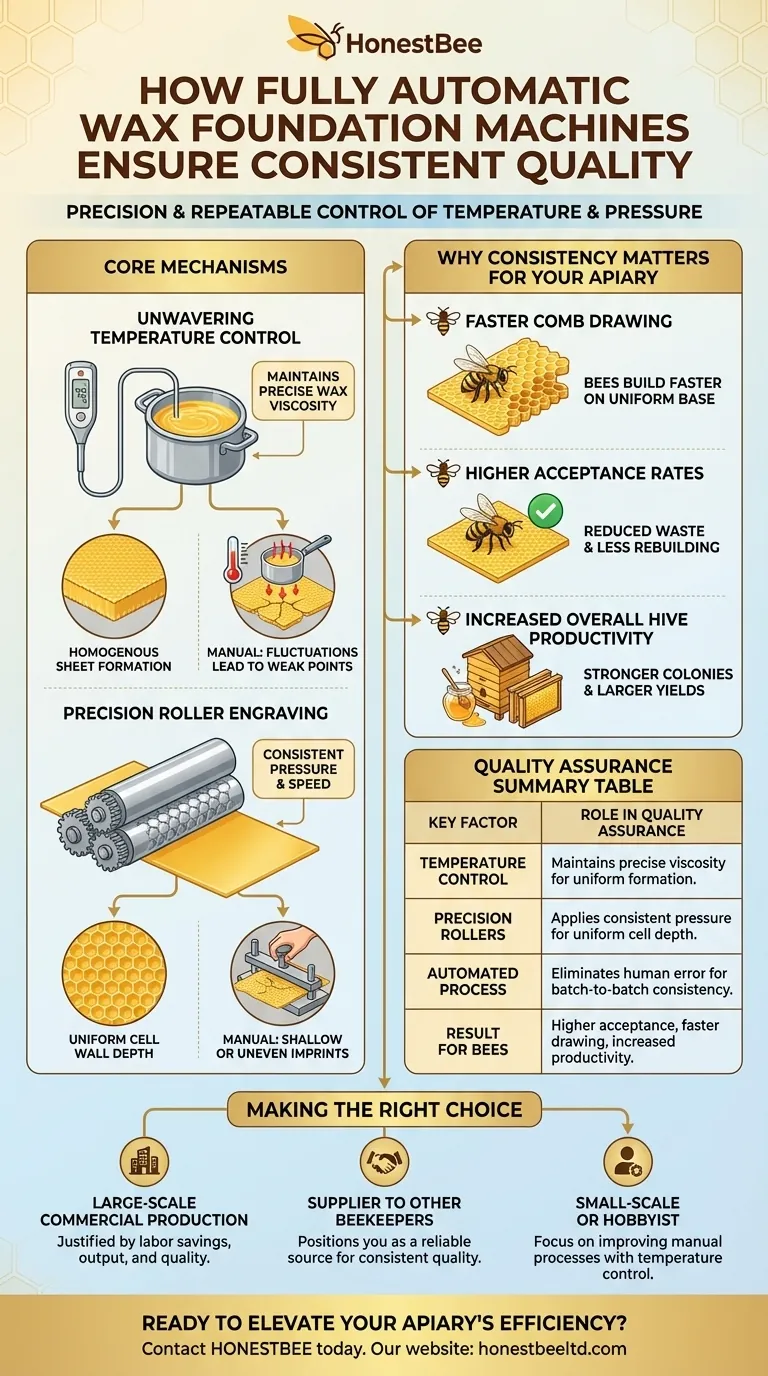

At its core, a fully automatic wax foundation machine ensures consistent quality through the precise and repeatable control of two critical variables: temperature and pressure. By removing human inconsistency from the process, these machines create a perfectly uniform product batch after batch, from the melting of the wax to the final imprinted sheet.

The fundamental advantage of full automation is the elimination of human variability. By mechanizing the sensitive processes of wax heating, sheet forming, and pattern imprinting, these machines produce a foundation that is more uniform and more readily accepted by bees than any manual method can consistently achieve.

The Core Mechanisms of Consistency

A fully automatic machine functions as an integrated system where each stage is optimized to produce a predictable outcome. This system is built on a few key engineering principles.

Unwavering Temperature Control

The temperature of the beeswax is the single most important factor in foundation quality. Automation maintains this with precision.

An integrated heating system keeps the liquid wax at an exact, constant temperature. This ensures the wax has the perfect viscosity to flow evenly and form a homogenous sheet without weak points.

In contrast, manual methods often lead to temperature fluctuations, resulting in sheets that are either too brittle (if cooled too quickly) or too soft (if poured too hot).

Precision Roller Engraving

The machine feeds the smooth wax sheet through a set of engraved rollers to imprint the honeycomb cell pattern.

These rollers apply perfectly consistent pressure and speed across the entire sheet. This creates uniform cell wall depth and thickness, giving the bees an ideal and predictable guide for comb construction.

Human-operated presses cannot replicate this level of uniformity, often resulting in shallow or uneven imprints that bees may ignore or have to rework.

Uniform Sheet Thickness

The combination of controlled temperature and regulated roller speed results in a foundation sheet with exact, uniform thickness.

This is crucial because it ensures bees expend a consistent amount of their own energy and resources to draw out the comb. Non-uniform sheets can slow down comb building and lead to wasted bee effort.

Why This Consistency Matters for Your Apiary

The output of the machine is not just a product; it's a tool for your bees. The quality of that tool directly impacts hive efficiency and productivity.

Faster and More Uniform Comb Drawing

Bees build faster on a perfect foundation. When the cell bases are uniform and well-defined, the colony can immediately begin drawing out the comb for brood rearing or honey storage.

This accelerates hive development and allows the colony to capitalize on nectar flows more quickly.

Higher Acceptance Rates

Bees can be selective. They may chew through, ignore, or rebuild sections of poor-quality foundation that have imperfections, inconsistent thickness, or shallow cell patterns.

The high uniformity of machine-made foundation leads to significantly higher acceptance rates, reducing waste and ensuring the frames are used as intended.

Increased Overall Hive Productivity

Faster comb drawing and less time spent fixing imperfections translate directly to a more productive hive. The colony can dedicate more of its workforce to foraging, honey production, and raising brood, leading to stronger colonies and larger honey yields.

Understanding the Trade-offs

While the benefits are clear, a fully automatic machine is a significant investment that requires careful consideration of its downsides.

Manual Production Inconsistency

The primary problem automation solves is human error. Manual methods, whether hand-dipping or using a small press, are subject to variations in temperature, timing, and pressure. This inevitably leads to a less consistent product.

The High Initial Investment

Fully automatic wax foundation machines represent a substantial capital expenditure. The cost is the single biggest barrier for small-scale beekeepers and hobbyists.

The return on this investment is typically only realized in large commercial operations where labor savings and output volume can justify the cost.

Maintenance and Operational Skill

These are not simple plug-and-play devices. They require proper calibration, regular cleaning, and periodic maintenance to continue functioning at peak performance.

Operating the machine effectively requires training and a degree of technical skill to manage the system and troubleshoot any issues that may arise.

Making the Right Choice for Your Operation

Deciding whether to invest in an automatic machine depends entirely on the scale and goals of your beekeeping enterprise.

- If your primary focus is large-scale commercial production: The investment is almost always justified by labor savings, increased output, and the superior quality of your final product.

- If your primary focus is supplying equipment or foundation to other beekeepers: An automatic machine positions you as a reliable source for high-quality, consistent foundation, building a strong reputation.

- If your primary focus is a small-scale or hobbyist apiary: The cost is likely prohibitive, but the principles of automation should guide you to improve your manual processes by focusing on temperature control and consistent technique.

Ultimately, embracing automation is an investment in the predictability and efficiency of your entire beekeeping enterprise.

Summary Table:

| Key Factor | Role in Quality Assurance |

|---|---|

| Temperature Control | Maintains precise wax viscosity for uniform sheet formation without weak points. |

| Precision Rollers | Applies consistent pressure and speed for uniform cell depth and pattern. |

| Automated Process | Eliminates human error, ensuring batch-to-batch consistency in thickness and imprint. |

| Result for Bees | Higher acceptance rates, faster comb drawing, and increased hive productivity. |

Ready to elevate your apiary's efficiency with professional-grade foundation?

As a trusted wholesale supplier to commercial apiaries and equipment distributors, HONESTBEE provides the durable, high-performance equipment needed for large-scale success. Our fully automatic wax foundation machines are engineered for maximum output and unwavering quality, helping you build stronger hives and increase honey yields.

Contact HONESTBEE today to discuss your operation's needs and discover how our beekeeping solutions can drive your growth.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What is the function of foundation sheet processing machinery? Boost Honey Yields and Bee Efficiency

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production