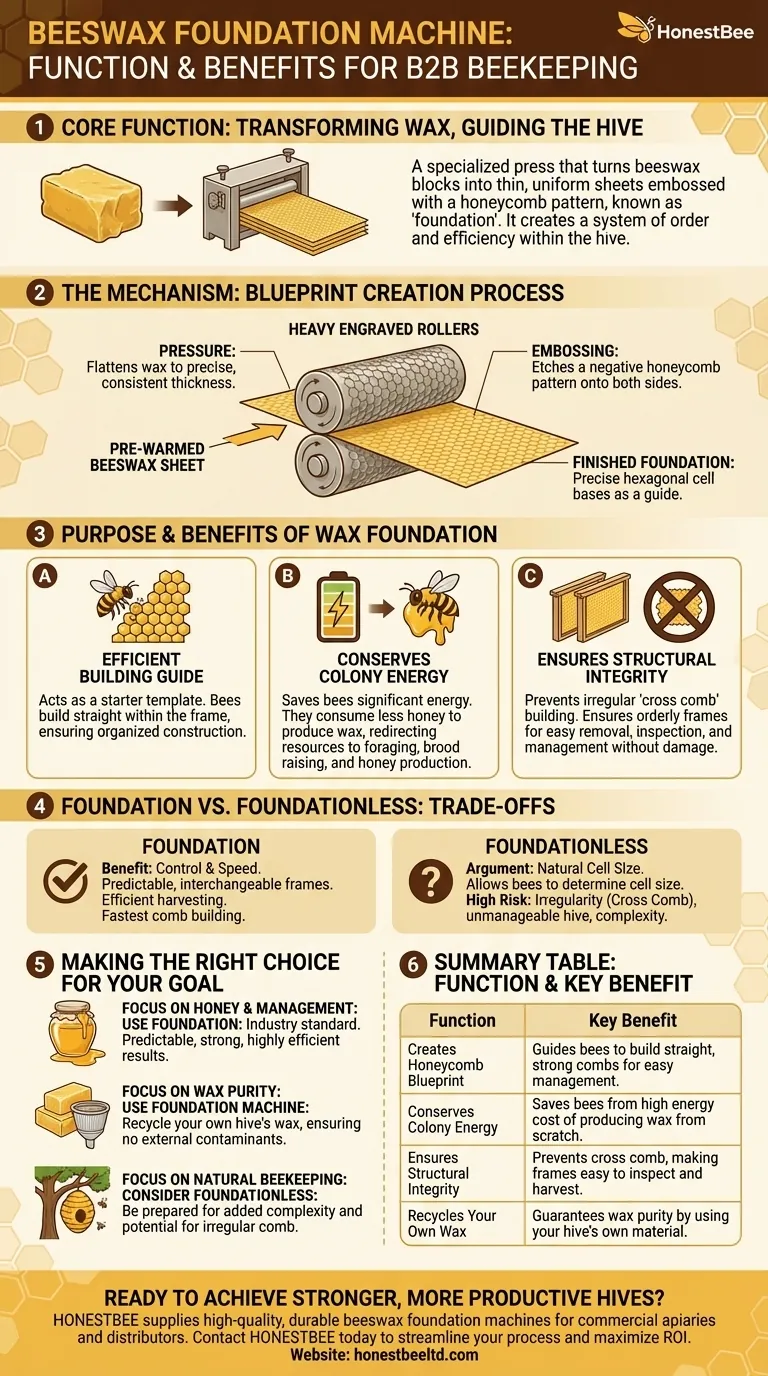

At its core, a beeswax foundation machine is a specialized press designed to transform blocks of pure beeswax into thin, uniform sheets embossed with a perfect honeycomb pattern. These sheets, known as "foundation," are then installed into beehive frames to provide the colony with a precise blueprint, guiding them on where and how to build their wax comb.

The true function of this machine is not merely to shape wax, but to create a system of order and efficiency within the hive. By providing a structured guide, it directs the bees' natural construction instincts, resulting in stronger, more uniform combs that are significantly easier for the beekeeper to manage and harvest.

How the Machine Creates the Blueprint

A foundation machine works through a simple but highly effective mechanical process. It translates raw beeswax into a functional guide for the entire colony.

The Core Mechanism: Rollers and Pressure

The most common design consists of two heavy, engraved rollers mounted horizontally in a sturdy frame. A sheet of smooth, pre-warmed beeswax is fed between these rollers.

The immense pressure flattens the wax to a precise, consistent thickness, which is critical for its acceptance and use by the bees.

Embossing the Hexagonal Pattern

The surface of each roller is etched with the negative imprint of a honeycomb base. As the wax sheet passes through, this pattern is permanently embossed onto both sides.

The result is a finished foundation sheet with the distinct hexagonal cell bases that bees recognize instinctively as a starting point for construction.

The Purpose of a Wax Foundation

Placing foundation in a hive is one of the most important inventions in modern beekeeping. It fundamentally improves the relationship between the beekeeper and the colony.

A Guide for Efficient Building

The foundation sheet is not a finished comb; it is a starter template. The bees use the embossed hexagonal bases as a guide to begin "drawing out" the comb, building up the cell walls to create the complete honeycomb structure.

This ensures the comb is built straight within the frame, which is essential for hive management.

Conserving the Colony's Energy

Producing beeswax is an incredibly energy-intensive process for honeybees. It's estimated they consume several pounds of honey to produce just one pound of wax.

By providing a foundation, the beekeeper gives the colony a massive head start, saving them significant energy and resources that can be redirected toward foraging, raising brood, and producing honey.

Ensuring Structural Integrity

Without a guide, bees may build "cross comb"—wax built irregularly across multiple frames. This makes it impossible for a beekeeper to remove a single frame for inspection without destroying the comb, killing brood, and potentially injuring the queen.

Foundation ensures orderly, parallel combs that are easily removed, inspected, and managed.

Understanding the Trade-offs: Foundation vs. Foundationless

While foundation is the standard, it's important to understand the alternative approach to appreciate its function fully.

The Benefit of Foundation: Control and Speed

Using foundation gives the beekeeper control over the hive's internal structure. It leads to predictable, interchangeable frames that are crucial for efficient honey harvesting and routine health inspections. It is the fastest way to get a colony to build usable comb.

The Argument for Foundationless: Natural Cell Size

Some beekeepers prefer foundationless beekeeping, allowing bees to build their comb entirely from scratch on a blank frame. The primary argument is that this allows bees to determine their own natural cell size, which some believe helps in managing pests like Varroa mites.

The Inherent Risk: Irregularity

The major drawback of going foundationless is the high risk of cross comb, especially for newer beekeepers. This can quickly lead to an unmanageable hive, negating the benefits of the modern removable-frame system.

Making the Right Choice for Your Goal

Understanding the function of a beeswax foundation machine helps you decide how to manage your apiary.

- If your primary focus is honey production and ease of management: Using a foundation is the industry standard. It delivers predictable, strong, and highly efficient results.

- If your primary focus is controlling the purity of your wax: A foundation machine is invaluable, as it allows you to recycle wax from your own hives, ensuring no external contaminants are introduced via commercial foundation.

- If your primary focus is a "hands-off" natural beekeeping philosophy: You might consider foundationless beekeeping, but you must be prepared for the added complexity and potential for irregular, unmanageable comb.

Ultimately, the beeswax foundation machine is a critical tool that bridges the gap between the bees' natural instincts and the beekeeper's need for a stable, productive hive.

Summary Table:

| Function | Key Benefit |

|---|---|

| Creates a Honeycomb Blueprint | Guides bees to build straight, strong combs for easy hive management. |

| Conserves Colony Energy | Saves bees from the high energy cost of producing wax from scratch. |

| Ensures Structural Integrity | Prevents cross comb, making frames easy to inspect and harvest. |

| Recycles Your Own Wax | Guarantees wax purity by using your hive's own material. |

Ready to achieve stronger, more productive hives?

For commercial apiaries and distributors, a reliable foundation machine is key to operational efficiency and honey yield. HONESTBEE supplies high-quality beekeeping equipment, including durable beeswax foundation machines, through our wholesale-focused operations.

Contact HONESTBEE today to discuss how our equipment can streamline your beekeeping process and maximize your return on investment.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Fully Automatic Beeswax Embossing Machine Foundation Mill

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- Why is the introduction of a beeswax foundation machine considered an important step in improving honey yields?

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- How do fully automatic wax foundation machines benefit beekeepers? Boost Efficiency & Scale Your Apiary