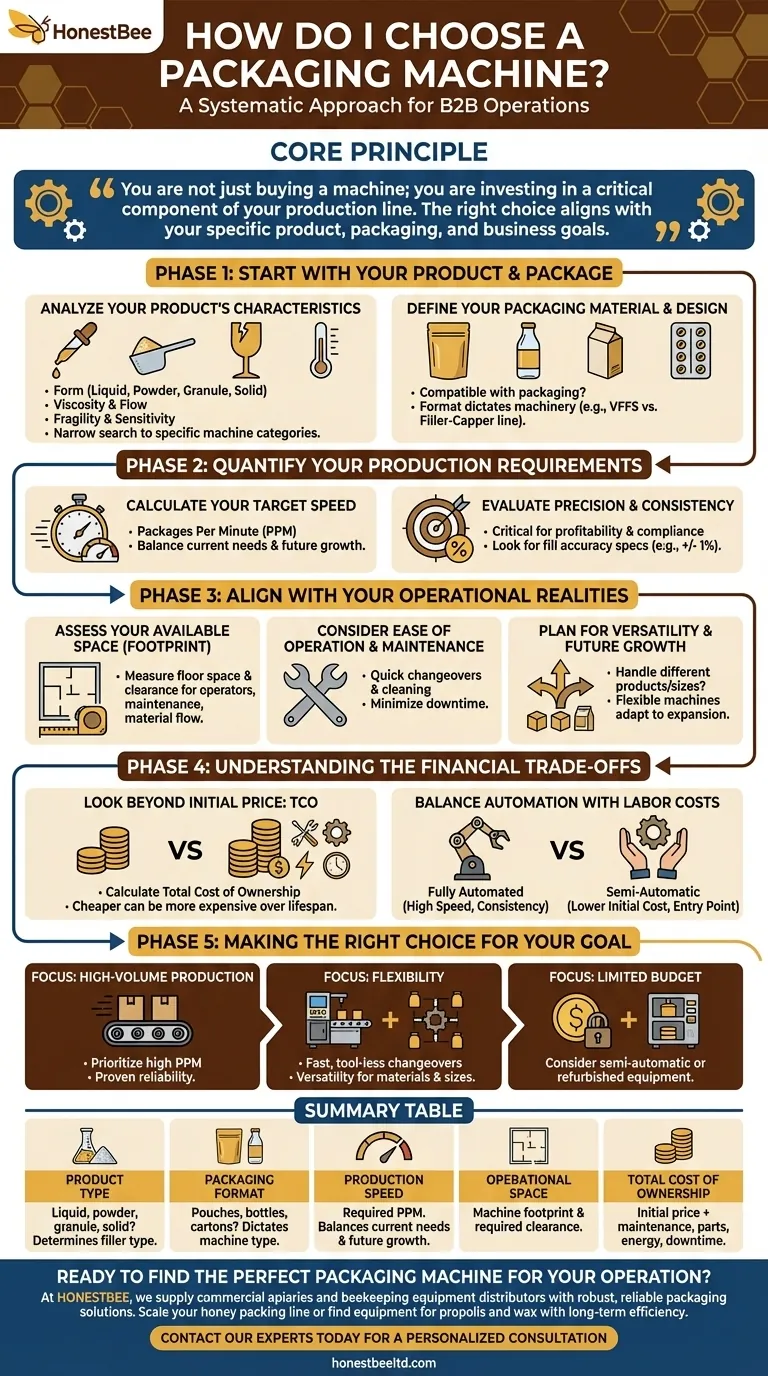

To choose the right packaging machine, you must move beyond a simple feature comparison and instead conduct a systematic evaluation of your product, production volume, and operational environment. The key factors to analyze are your product's characteristics (like viscosity or fragility), your required output speed, the type of packaging material you use, and the machine's long-term cost-effectiveness and ease of maintenance.

The core principle is this: You are not just buying a machine; you are investing in a critical component of your production line. The right choice is not the most advanced or cheapest machine, but the one that aligns most precisely with your specific product, packaging, and business goals.

Start with Your Product and Package, Not the Machine

The most common mistake is to shop for machinery first. The machine is a tool designed to handle a specific task. To choose the right tool, you must first have an absolute understanding of the task itself.

Analyze Your Product's Characteristics

Your product's physical properties are the single most important factor. A machine designed for dry powders will fail if used for viscous liquids.

Consider its form (liquid, solid, powder, granule), viscosity, fragility, and temperature sensitivity. This will immediately narrow your search to specific machine categories, such as auger fillers for powders or piston fillers for thick liquids.

Define Your Packaging Material and Design

The machine must be compatible with your chosen packaging. Are you using flexible pouches, rigid bottles, cartons, or blister packs?

The packaging format dictates the type of machinery required. For example, a stand-up pouch requires a Vertical Form Fill Seal (VFFS) machine or a pre-made pouch filler, while a glass bottle requires a completely different line with a filler, capper, and labeler.

Quantify Your Production Requirements

Once the product and package are defined, you must quantify your performance needs. "Fast" is not a useful metric; you need specific targets.

Calculate Your Target Speed (Packages Per Minute)

Determine your required throughput in Packages Per Minute (PPM) or Bags Per Minute (BPM). This is the primary specification that separates entry-level equipment from high-output automated systems.

Be realistic about your current needs but also consider future growth. A machine that is too slow creates a bottleneck, while one that is too fast may be an unnecessary capital expense.

Evaluate Precision and Consistency Needs

Precision is critical for profitability and compliance. A machine with poor fill accuracy gives away product with every package, eroding margins over time.

Look for specifications on fill accuracy (e.g., +/- 1%). Consistent, repeatable performance ensures product quality and brand integrity.

Align with Your Operational Realities

A machine does not operate in a vacuum. It must fit within your facility, your team's skillset, and your long-term business strategy.

Assess Your Available Space (Footprint)

Measure your available floor space precisely. Remember to account not only for the machine's footprint but also for the necessary clearance for operators, maintenance access, and material staging (both inbound and outbound).

Consider Ease of Operation and Maintenance

Complex machinery can lead to significant downtime if it requires specialized technicians for simple changeovers or cleaning.

Evaluate how quickly and easily the machine can be cleaned and changed over to a different product or package size. This directly impacts your operational efficiency.

Plan for Versatility and Future Growth

Ask yourself if you will need to handle different products or package sizes in the future.

Some machines are highly specialized for one task, while others offer versatility and adaptability. Investing in a more flexible machine can be a wise decision if you anticipate expanding your product line.

Understanding the Financial Trade-offs

The sticker price of a machine is only one part of its true cost. A thorough financial analysis prevents surprises and ensures a positive return on investment.

Look Beyond the Initial Purchase Price

You must calculate the Total Cost of Ownership (TCO). This includes the initial purchase price plus the ongoing costs of maintenance, spare parts, energy consumption, and potential downtime.

A cheaper machine with high maintenance needs can easily become more expensive over its lifespan than a higher-quality, more reliable alternative.

Balance Automation with Labor Costs

Evaluate the level of automation that is appropriate for your operation. A fully automated line reduces labor costs and can run with higher speed and consistency.

However, semi-automatic machines have a lower initial cost and can be a perfect entry point for smaller businesses, providing a significant upgrade over manual processes.

Making the Right Choice for Your Goal

Ultimately, your decision should be guided by your primary business objective.

- If your primary focus is high-volume production: Prioritize machines with a high Packages Per Minute (PPM) rating and proven reliability to minimize downtime.

- If your primary focus is flexibility for multiple products: Seek out machines with fast, tool-less changeovers and the versatility to handle different materials and sizes.

- If your primary focus is a limited budget: Consider semi-automatic machines or refurbished equipment from reputable dealers that can deliver consistency without the high capital cost of full automation.

Choosing the right packaging machine is a methodical process of aligning your specific needs with the right technical solution.

Summary Table:

| Key Factor | What to Consider |

|---|---|

| Product Type | Liquid, powder, granule, solid? Determines filler type (e.g., piston, auger). |

| Packaging Format | Pouches, bottles, cartons? Dictates machine type (e.g., VFFS, filler-capper). |

| Production Speed | Required Packages Per Minute (PPM). Balances current needs and future growth. |

| Operational Space | Machine footprint and required clearance for access and material flow. |

| Total Cost of Ownership | Initial price plus maintenance, parts, energy, and potential downtime costs. |

Ready to find the perfect packaging machine for your operation?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, reliable packaging solutions designed for high-volume and versatile needs. Whether you're scaling your honey packing line or need equipment for propolis and wax, we help you invest wisely for long-term efficiency and profitability.

Contact our experts today for a personalized consultation to match your specific product and production goals with the ideal machinery.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Dual Sided In Line Labeling Machine

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

- Professional Durable Customizable Blister Packing Machine

- Automatic In-Line Flat Surface Labeling Machine

People Also Ask

- What role do industrial honey-filling machines play in food safety? Elevate Standards with HONESTBEE Automation

- What are the basic components of a honey stick machine and their functions? Expert Guide to Key Parts

- Why are industrial automated filling and packaging machines critical for bee pollen? Protect Potency and Scale Output

- How do industrial-grade automatic honey filling machines enhance commercial value? Scale Your Apiary Efficiency

- What is the importance of versatility and adaptability in a honey packaging machine? Future-Proof Your Production

- What advantages does specialized honey filling machinery offer? Scale Your Production with Automated Precision

- What is the significance of automatic honey-filling machines? Scaling Your Forest Honey Production

- What core processing challenges are addressed by automated honey-filling machines? Boost Your Honey Production Now