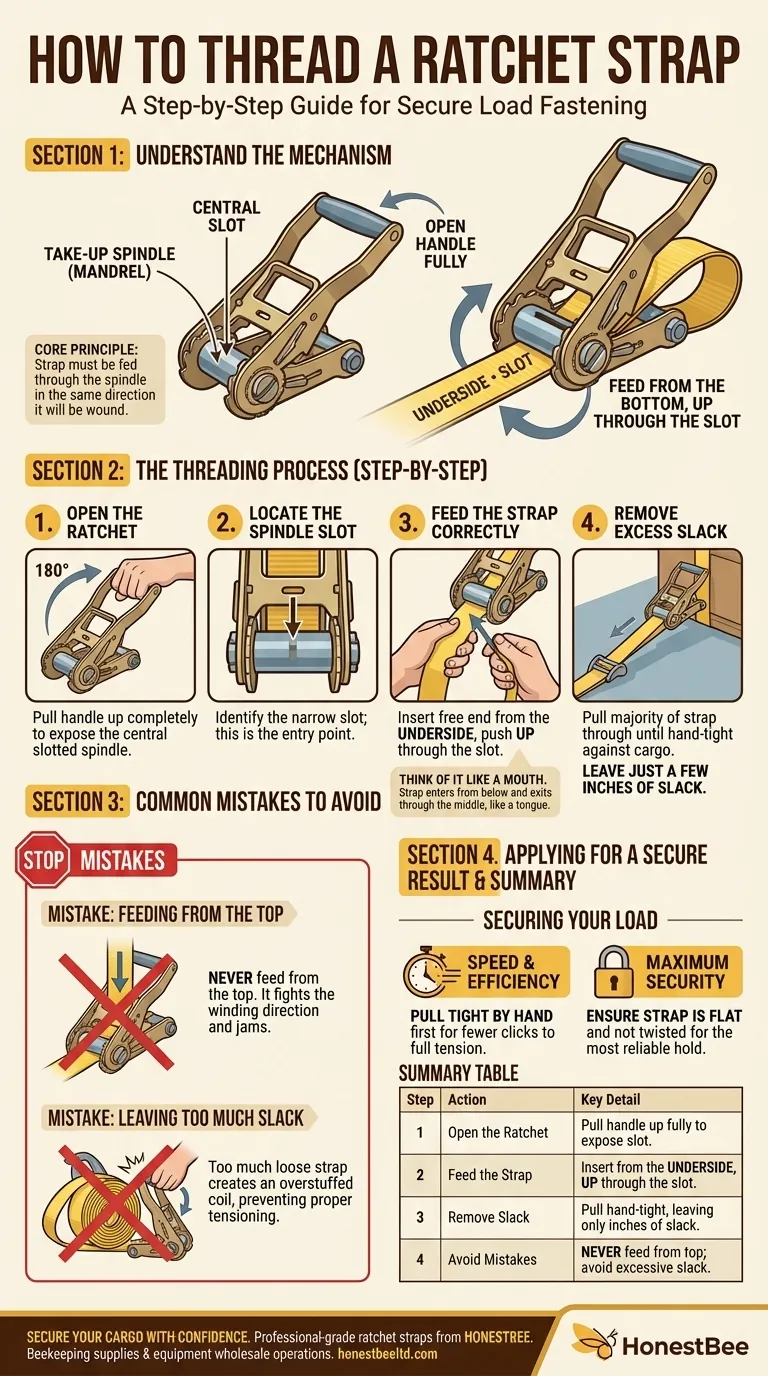

To thread a ratchet strap, you must first open the ratchet handle completely to expose the central, slotted spindle. You then feed the loose end of the strap from the bottom (or back) of the ratchet, up through the slot in this spindle. Pull the excess strap all the way through until it is taut, leaving just a few inches of slack to work with.

The core principle is simple: the strap must be fed through the spindle in the same direction it will be wound. Feeding it from the bottom ensures that as you crank the handle, the spindle neatly wraps the strap around itself, creating tension.

The Logic of the Ratchet Mechanism

To use a ratchet strap correctly and safely, it helps to understand its basic components. The mechanism is designed for one-way tensioning, and feeding the strap properly is the critical first step.

Step 1: Open the Ratchet Assembly

First, fully open the ratchet by pulling up on the handle. This disengages the locking mechanism and allows the central spindle to rotate freely.

Opening the handle exposes the take-up spindle (also called a mandrel), which is the rotating cylinder in the middle of the mechanism.

Step 2: Locate the Spindle Slot

You will see a narrow opening, or slot, that runs through the center of this spindle. This slot is the entry point for your strap.

Step 3: Feed the Strap Correctly

Take the free, non-hooked end of your webbing. Insert it from the underside of the ratchet assembly and push it up through the slot.

Think of the open ratchet as a mouth. The strap should come from below and exit through the middle, like a tongue.

Step 4: Remove the Excess Slack

Pull the majority of the strap's length through the slot until it is hand-tight against your cargo. You should only have a small amount of slack (e.g., 6 inches) between the ratchet and the other anchor point.

This is a critical step. Failing to remove slack by hand means you will have to wind the entire strap length onto the spindle, which can cause it to overfill and jam.

Common Threading Mistakes to Avoid

Incorrectly threading the strap is the most common reason a ratchet fails to tighten. Understanding these errors will ensure you get it right every time.

Mistake: Feeding from the Top

Never feed the strap down through the slot from the top. If you do this, the strap will be fighting the winding direction of the spindle. It will bunch up, jam, and fail to create any meaningful tension.

Mistake: Leaving Too Much Slack

If you start ratcheting with several feet of loose strap, the spindle will quickly become a thick, overstuffed coil. This can prevent the ratchet from closing properly or achieving the necessary tension before the spindle runs out of space.

Applying This for a Secure Result

Your goal determines how you approach the final tightening.

- If your primary focus is speed and efficiency: Pull the strap as tight as you possibly can by hand before you even begin to crank the ratchet. This ensures you only need a few clicks to achieve full tension.

- If your primary focus is maximum security: As you pull the slack through, ensure the strap is perfectly flat and not twisted. A flat, even wind on the spindle provides the most reliable hold.

- If you are just learning: Before securing a load, practice feeding the strap and cranking the handle a few times. Watching how the strap coils onto the spindle will make the correct feeding path intuitive.

Mastering this simple threading process is the key to using your ratchet straps safely and effectively.

Summary Table:

| Step | Action | Key Detail |

|---|---|---|

| 1 | Open the Ratchet | Pull the handle up fully to disengage the lock and expose the spindle slot. |

| 2 | Feed the Strap | Insert the free end from the underside of the ratchet, pushing it up through the spindle slot. |

| 3 | Remove Slack | Pull the strap hand-tight against the cargo, leaving only a few inches of slack. |

| 4 | Avoid Mistakes | Never feed from the top; avoid starting with excessive slack to prevent jamming. |

Secure your cargo with confidence using professional-grade ratchet straps from HONESTBEE. We supply durable, reliable beekeeping supplies and equipment, including essential load-securing gear, to commercial apiaries and distributors through our wholesale operations. Ensure every load is safe and secure—contact our experts today to discuss your equipment needs and wholesale pricing!

Visual Guide

Related Products

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

- 3.5L Plastic Beehive Frame Feeder Deep Frame Water Feeder for In Hive Use

- Professional Hive Top Bee Feeder for Beekeeping

- Premium Traditional Copper Bee Smoker with Bellows

People Also Ask

- What finish options are available for wooden beehives? Choose the Best Protection for Your Apiary

- How should new wooden beekeeping equipment be prepared for use? Pro Tips for Maximum Hive Durability

- What components are typically included in a wooden beehive set? A Complete Guide to Professional Hive Structures

- How do wood color and properties influence honey bee nesting? Boost Hive Occupancy with White and Yellow Tones

- What is the best place to keep bees? Find the Perfect Apiary Site for Your Hives