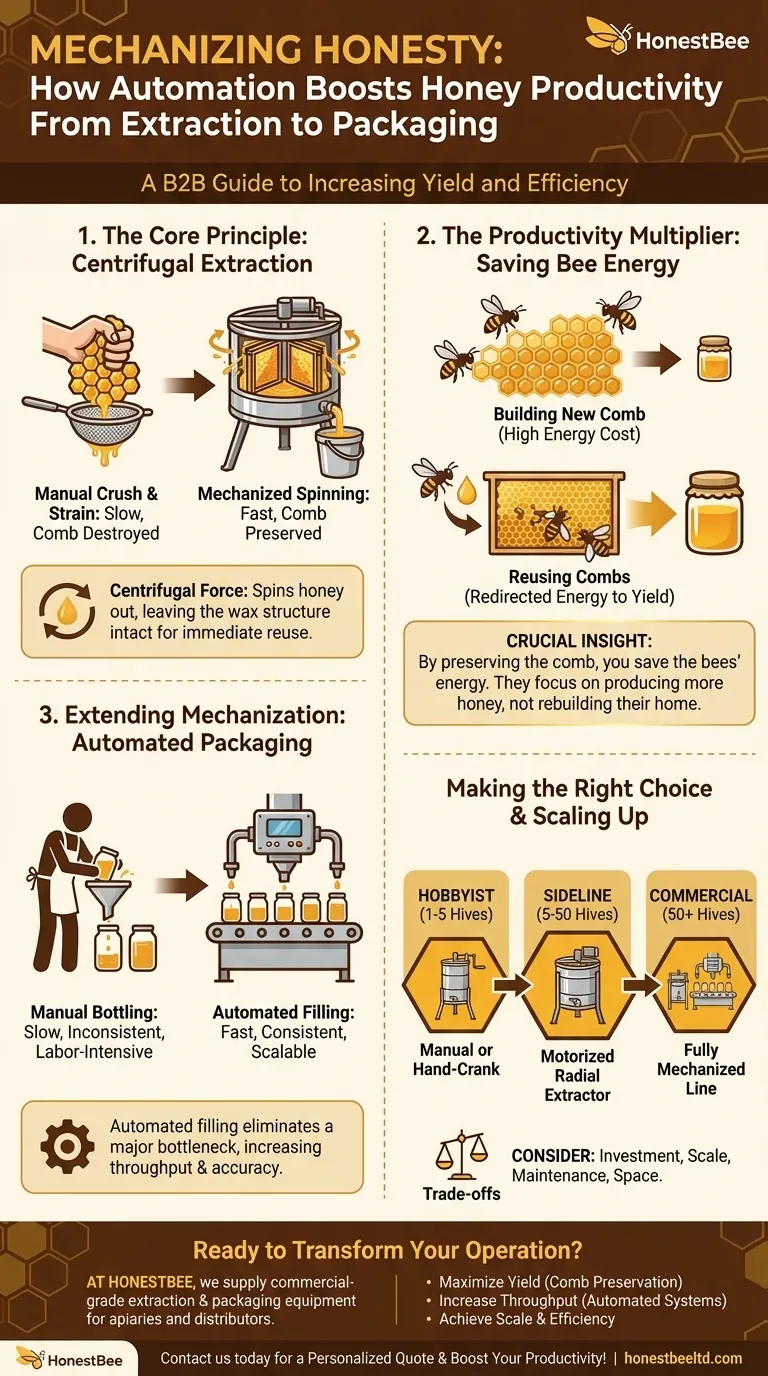

At its core, mechanizing the honey extraction process improves productivity by dramatically increasing the speed of extraction, preserving the delicate honeycomb for immediate reuse, and automating the final packaging. This allows both the beekeeper and the honeybees to operate far more efficiently.

The crucial insight is that mechanization doesn't just save human labor; it saves the bees' energy. By preserving the comb, you redirect the colony's efforts from rebuilding their home to producing more honey, which is the ultimate driver of increased yield.

The Core Principle: Centrifugal Extraction

The heart of mechanized extraction is the honey extractor, a device that uses centrifugal force to pull honey from the comb. This is a fundamental shift from traditional "crush and strain" methods.

How It Works

A honey extractor operates much like a salad spinner or the spin cycle on a washing machine. Frames of honeycomb are placed inside a drum, which then spins at high speed. This rotation generates a powerful outward force that flings the honey from the cells onto the inner wall of the drum, where it drips down to be collected.

Preserving the Comb's Integrity

Unlike manual methods that require destroying the comb to release the honey, centrifugal extraction leaves the wax structure almost perfectly intact. The frames are specially designed to withstand the spinning forces, ensuring the comb can be handled without falling apart. This preservation is the single most important aspect of the process.

The True Productivity Multiplier: Reusing Combs

Giving an empty, undamaged comb back to the bees is the key to unlocking their full production potential. The energy saved by not having to build new wax is immense.

The Energetic Cost of Wax Production

Bees must consume a significant amount of honey—their energy source—to produce beeswax. By providing them with ready-made comb, you eliminate this massive energy expenditure.

Redirecting Bee Energy to Honey Production

When bees don't have to build, they can focus entirely on their primary task: foraging for nectar and turning it into honey. This allows a colony to fill existing combs much faster than they could build new ones from scratch, leading to a direct and substantial increase in total honey yield per season.

Extending Mechanization to Packaging

For larger operations, productivity gains don't stop at extraction. The process of getting honey into jars is another major bottleneck that can be solved with machinery.

The Bottleneck of Bottling

Manually filling jars with honey is slow, messy, and often results in inconsistent fill levels. This process requires significant labor and can dramatically slow down your ability to get the final product to market.

Automated Filling for Speed and Consistency

A honey filling machine automates this final step. It dispenses precise amounts of honey into containers at high speed, significantly increasing throughput, reducing product waste, and freeing up labor for other critical tasks.

Understanding the Trade-offs

While mechanization offers clear benefits, it is not a one-size-fits-all solution. A clear-eyed assessment of the costs and requirements is necessary.

Initial Capital Investment

The primary drawback is cost. Honey extractors, uncapping tools, and filling machines represent a significant upfront investment. This can be a major barrier for new or small-scale beekeepers.

Required Scale of Operation

The return on investment for mechanized equipment is directly tied to the scale of your operation. The time and labor saved on ten or more hives can quickly justify the cost, but it may be an unnecessary expense for someone with only one or two.

Maintenance and Space

These machines require proper cleaning and maintenance to ensure they remain hygienic and functional. They also require dedicated space for operation and storage, which must be factored into your planning.

Making the Right Choice for Your Goal

Selecting the right level of mechanization depends entirely on your operational scale and business objectives.

- If your primary focus is hobbyist beekeeping (1-5 hives): The "crush and strain" method or a small, manual hand-crank extractor is often sufficient and more economical.

- If your primary focus is growing a sideline business (5-50 hives): A motorized radial extractor is a critical investment to save time and dramatically increase your potential honey yield.

- If your primary focus is commercial production (50+ hives): A fully mechanized line, including an automated uncapper and a bottle filling machine, is essential for profitability and operational efficiency.

Ultimately, investing in the right equipment transforms your operation from a labor-intensive hobby into a highly productive enterprise.

Summary Table:

| Mechanization Benefit | Key Impact on Productivity |

|---|---|

| Centrifugal Extraction Speed | Dramatically faster than manual methods, saving significant labor time. |

| Honeycomb Preservation | Saves bees' energy by allowing immediate comb reuse, increasing honey yield. |

| Automated Packaging | Fills jars with speed and consistency, eliminating a major bottling bottleneck. |

| Scalability | Enables efficient management of operations from sideline (5+ hives) to commercial scale (50+ hives). |

Ready to transform your beekeeping operation's productivity?

At HONESTBEE, we supply the commercial-grade honey extraction and packaging equipment that commercial apiaries and distributors rely on. Our wholesale-focused operations provide the durable, efficient machinery you need to:

- Maximize honey yield by preserving combs and saving bee energy.

- Dramatically increase throughput with automated extraction and filling.

- Achieve operational efficiency and profitability at scale.

Contact us today to discuss the right equipment for your specific needs and scale. Let's build a more productive future for your business together.

Get a Personalized Quote & Boost Your Productivity Now!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive

- What is the most common method for cleaning a honey extractor? Protect Your Honey & Equipment

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently

- What is the pressing method for extracting honey? A Simple, Low-Cost Approach for Small-Scale Beekeepers

- What is the principal idea in harvesting honey? A 3-Step Guide to a Responsible Harvest