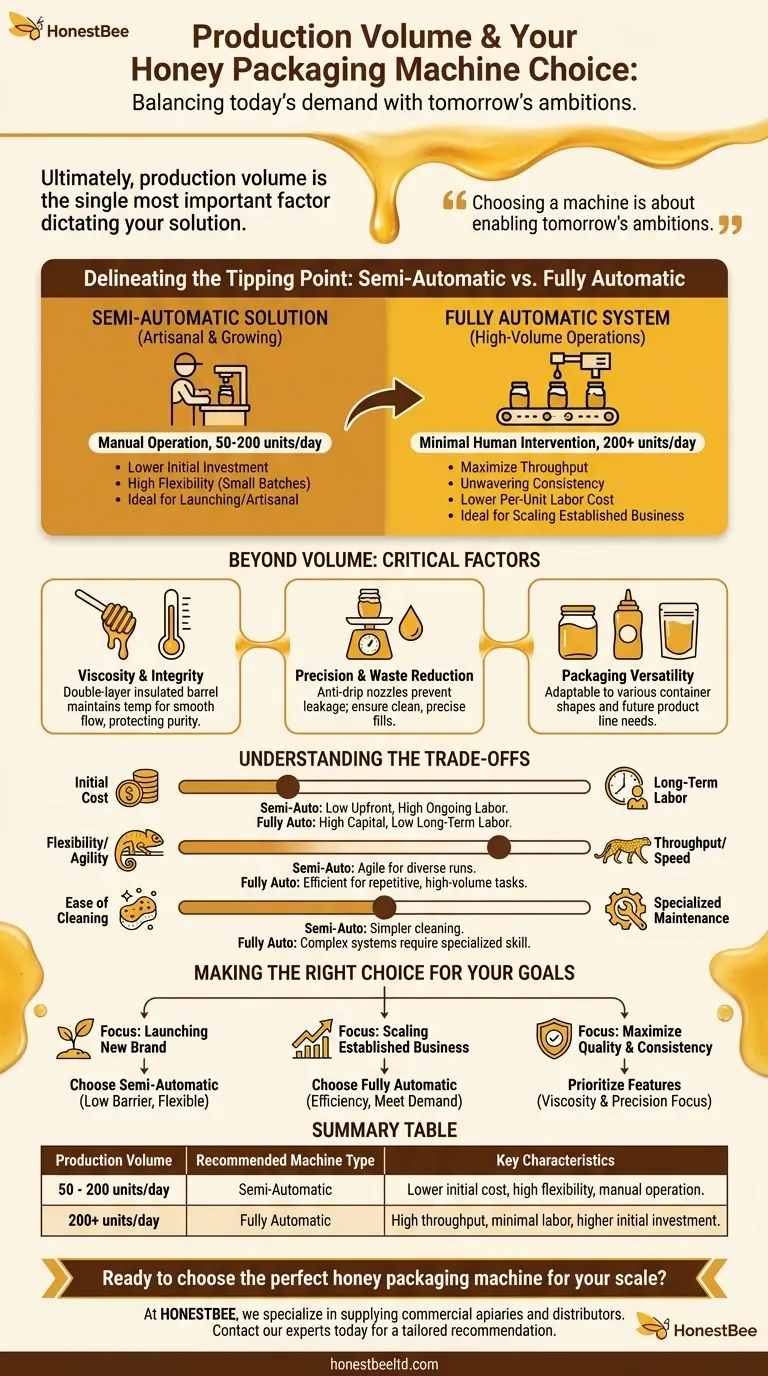

Ultimately, production volume is the single most important factor determining your choice of a honey packaging machine. It directly dictates whether your operation requires a semi-automatic solution for smaller batches or a fully automatic system for large-scale distribution. Small-scale producers filling 50 to 200 jars per day will find semi-automatic machines sufficient, while larger operations demand the high output of fully automated lines.

While your daily output is the starting point, the correct decision hinges on balancing initial investment against long-term labor costs and future growth. Choosing a machine is not just about meeting today's demand, but about enabling tomorrow's ambitions.

Delineating the Tipping Point: Semi-Automatic vs. Fully Automatic

The primary decision driven by volume is the level of automation. Each approach serves a distinct business scale and operational philosophy.

The Semi-Automatic Solution: For Artisanal and Growing Producers

A semi-automatic machine requires an operator to manually place containers for filling and then move them for capping or sealing.

This approach is ideal for businesses with lower production volumes, typically in the range of 50 to 200 units per day.

Its primary advantages are a lower initial investment and greater flexibility for handling various small batches or different container types without extensive changeover procedures.

The Fully Automatic System: For High-Volume Operations

A fully automatic system is an integrated production line that handles every step from container feeding to filling, capping, and labeling with minimal human intervention.

These systems are essential for large-scale producers who need to maximize throughput, ensure unwavering consistency, and reduce per-unit labor costs.

While the initial capital outlay is significant, the efficiency gains and speed are necessary for servicing large contracts and a wide distribution network.

Beyond Volume: Critical Factors for an Optimal Investment

A successful investment requires looking past the daily unit count and considering the nature of your product and the full scope of your operation.

Honey Viscosity and Product Integrity

Honey's thickness, or viscosity, changes with temperature. A quality machine may feature a double-layer insulated barrel to maintain consistent warmth, ensuring smooth, even flow and protecting the honey's purity.

The filling mechanism itself—whether a piston, pump, or other system—must be designed to handle your specific honey's viscosity without causing aeration or damage.

Precision and Waste Reduction

Accuracy is paramount. Overfilling wastes product and profit, while underfilling can harm your brand's reputation.

Look for features like anti-drip or suck-back devices on the filling nozzles. These prevent leakage between fills, ensuring clean packaging and precise, consistent volumes in every container.

Packaging Versatility and Adaptability

Your machine must be compatible with your chosen packaging, whether that's glass jars, plastic squeeze bottles, or flexible pouches.

Consider your future plans. A machine that can be adapted to handle different container shapes and sizes provides the versatility needed to evolve your product line.

Understanding the Trade-offs

Choosing the right machine involves a clear-eyed assessment of its costs and benefits over its entire lifecycle.

Initial Cost vs. Long-Term Labor

A semi-automatic machine has a much lower upfront cost, making it accessible for new businesses. However, it carries a higher ongoing cost in operator labor.

A fully automatic machine is a major capital expense but dramatically reduces labor costs over time, leading to a lower cost per unit at high volumes.

Flexibility vs. Throughput

The core trade-off is often between agility and speed. Semi-automatic systems excel at handling diverse, small-batch runs with quick changeovers.

Fully automatic lines are built for efficiency in repetitive, high-volume tasks. Changing container types can be more complex and time-consuming, making them less ideal for highly varied production.

Maintenance and Ease of Cleaning

All food-grade equipment requires rigorous cleaning. Evaluate how easily a machine can be disassembled, cleaned, and reassembled, as this directly impacts downtime.

More complex, fully automated systems may also require more specialized maintenance and technical skill to operate and service effectively.

Making the Right Choice for Your Production Goals

Your decision should be a strategic investment aligned with your specific business objectives.

- If your primary focus is launching a new brand or artisanal production: A semi-automatic machine offers the lowest financial barrier to entry and the highest flexibility for experimentation.

- If your primary focus is scaling an established business: A fully automatic system is necessary to increase efficiency, reduce operational costs, and meet growing market demand.

- If your primary focus is maximizing product quality and consistency: Prioritize machines with features that manage honey viscosity and ensure precise, drip-free fills, regardless of the automation level.

Ultimately, the right machine is one that not only meets your current production volume but also supports your long-term vision for growth.

Summary Table:

| Production Volume | Recommended Machine Type | Key Characteristics |

|---|---|---|

| 50 - 200 units/day | Semi-Automatic | Lower initial cost, high flexibility, manual operation. |

| 200+ units/day | Fully Automatic | High throughput, minimal labor, higher initial investment. |

Ready to choose the perfect honey packaging machine for your scale?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the right packaging solutions. Whether you're scaling an established brand or launching a new one, our wholesale-focused operations ensure you get the machinery that balances your current volume with future growth.

Contact our experts today to discuss your production goals and receive a tailored recommendation that maximizes your efficiency and protects your product quality.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How do automatic honey-filling machines facilitate the transition to retail? Professional Solutions for Beekeeping

- What is the significance of automated filling and labeling systems in honey quality? Build Consumer Trust with Precision

- Why is the integration of automated honey-filling machines necessary? Scale Your Commercial Honey Production Line

- How do automated honey-filling machines improve the honey post-processing stage? Scale Your Apiary Efficiency

- How do automated honey-filling machines ensure product quality? Secure Purity for Organic Honey Production