In a honey stick machine, the unwinding disk serves as the critical first step in the packaging process. Its function is to hold the large roll of packaging film and rotate in a controlled manner, feeding the flat film into the rest of the machine for forming, filling, and sealing.

The unwinding disk is more than a simple spool; it is the motor-driven starting point of a synchronized assembly line. Its precise rotation dictates the pace and consistency for every subsequent step, from forming the tube to the final sealed product.

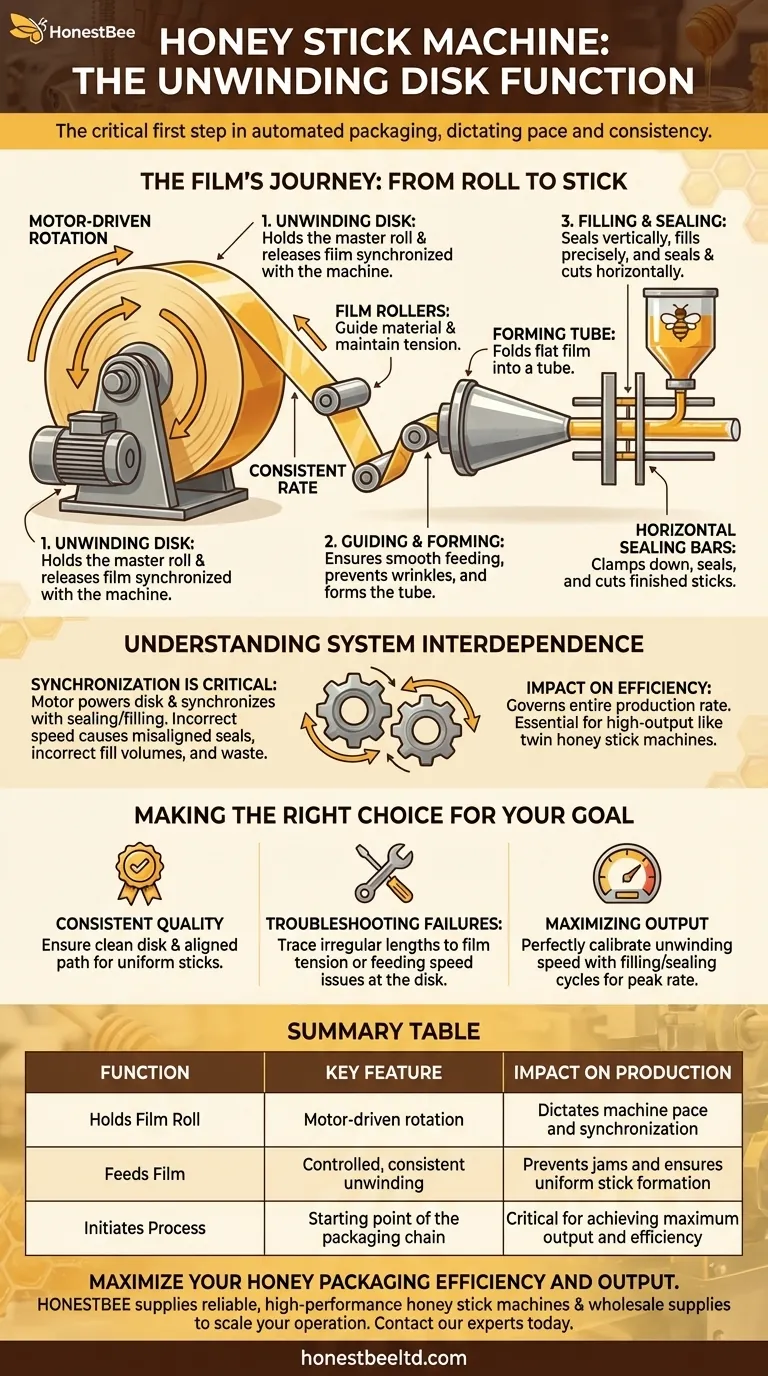

The Film's Journey: From Roll to Stick

To fully grasp the unwinding disk's importance, you must understand its place within the machine's overall workflow. The entire operation is a synchronized sequence of events that transforms a flat film into a finished honey stick.

Step 1: The Unwinding Process

The unwinding disk holds the master roll of packaging film. Powered by the machine's central motor, it rotates to release the film at a consistent rate. This motorized action ensures the film feeds smoothly and without interruption.

Step 2: Guiding and Forming

After leaving the unwinding disk, the film passes over a series of film rollers. These rollers guide the material and maintain proper tension, preventing wrinkles or slack. It then enters the forming tube, a conical component that folds the flat film into the characteristic stick or tube shape.

Step 3: Filling and Sealing

Once the tube is formed, it is sealed vertically along its length. The product hopper then dispenses a precise amount of honey into the formed tube. Finally, a set of horizontal sealing bars clamps down, sealing the top of one stick and the bottom of the next, while simultaneously cutting them apart.

Understanding the System's Interdependence

A honey stick machine is not a collection of independent parts but a highly integrated system. The function of the unwinding disk is directly tied to the performance of every other component.

The Critical Role of Synchronization

The machine's motor doesn't just power the unwinding disk; it synchronizes its rotation with the action of the sealing bars and the filling mechanism. If the disk unwinds film too quickly or too slowly, it will cause misaligned seals, incorrect fill volumes, and material waste.

The Impact on Production Efficiency

The entire production rate is governed by this synchronized system. For high-output equipment, such as a twin honey stick machine that produces two sticks at once, the reliability of the unwinding and film-feeding process is even more critical to achieving maximum efficiency.

Making the Right Choice for Your Goal

Understanding how the unwinding disk initiates the process allows you to operate and troubleshoot your machine more effectively.

- If your primary focus is consistent quality: Ensure the unwinding disk and film path are clean and perfectly aligned to prevent jams and ensure uniform stick formation.

- If your primary focus is troubleshooting failures: Irregular stick lengths or inconsistent seals can often be traced back to issues with film tension or feeding speed, which originates at the unwinding disk.

- If your primary focus is maximizing output: The speed of the unwinding mechanism must be perfectly calibrated with the filling and sealing cycles to run the machine at its peak rated speed without errors.

Recognizing the unwinding disk as the starting point for the entire packaging chain is fundamental to mastering your machine's operation.

Summary Table:

| Function | Key Feature | Impact on Production |

|---|---|---|

| Holds Film Roll | Motor-driven rotation | Dictates machine pace and synchronization |

| Feeds Film | Controlled, consistent unwinding | Prevents jams and ensures uniform stick formation |

| Initiates Process | Starting point of the packaging chain | Critical for achieving maximum output and efficiency |

Maximize your honey packaging efficiency and output. The unwinding disk is just one critical component. For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies the reliable, high-performance honey stick machines and wholesale beekeeping supplies you need to scale your operation. Contact our experts today to find the perfect packaging solution for your business.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

People Also Ask

- What role does automated honey-filling machinery play in preventing contamination? Ensure Pure, Safe Honey Production

- What role do industrial honey filling machines play in medicinal honey? Secure Potency with Precision Packaging

- How can honey flow and weight consistency be optimized? Master Bottling with Temperature and Precision Control

- What role do honey-filling machines play in the commercialization of wild honey? From Raw Harvest to Global Retail

- Why are high-precision honey-filling machines critical? Master Global Export Standards and Maximize Your Profitability

- How do high-precision honey-filling machines ensure product quality? Optimize Your Wild Grassland Honey Packaging

- What types of products are piston filling machines particularly suited for? Perfect Solutions for Thick & Chunky Liquids

- Why is industrial honey filling equipment necessary for medical and cosmetic grades? Upgrade Your Purity & Efficiency