To prepare beeswax for marketing, it is rendered by melting it to separate impurities, filtering the liquid wax, and then molding it into clean, solid blocks for shipment. This process must avoid contact with reactive metals like iron or zinc, which can damage the wax.

The entire goal of beeswax processing is purification. The method, known as rendering, simply uses heat to melt the wax, allowing debris to be filtered out, resulting in a clean, high-quality product ready for market.

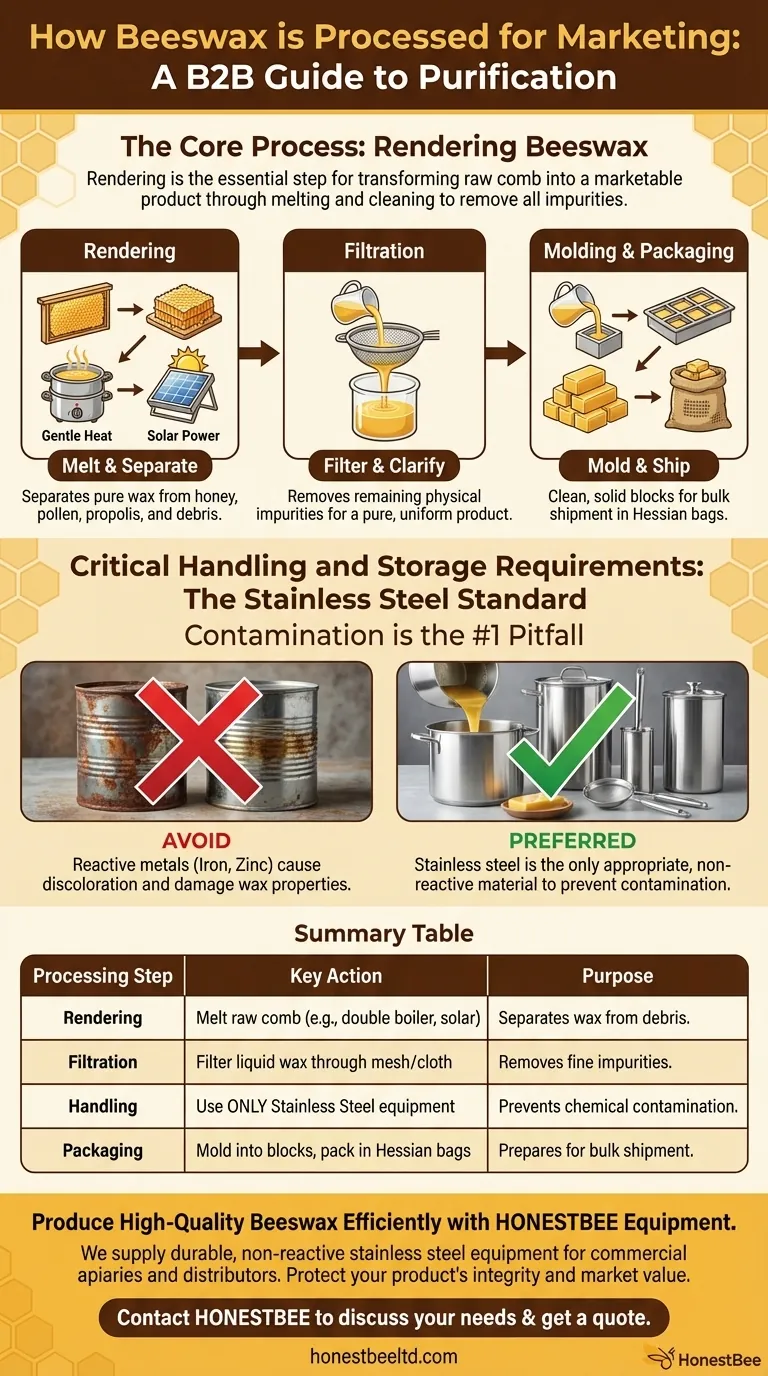

The Core Process: Rendering Beeswax

Rendering is the essential step for transforming raw comb into a marketable product. It is a process of melting and cleaning the wax to remove all impurities.

The Goal of Purification

Raw beeswax from the hive contains honey residue, pollen, propolis, and other debris. Rendering separates the pure wax from these impurities, improving its quality, appearance, and stability.

Common Melting Methods

The most common methods use gentle, indirect heat to avoid scorching the wax. Double boilers are frequently used, as is a more passive approach using solar melters, which use the sun's heat to slowly melt the wax and separate it from debris.

The Importance of Filtration

Once melted, the liquid wax is filtered. This step removes any remaining physical impurities, ensuring the final product is pure and uniform. The result is clean, clarified beeswax.

Critical Handling and Storage Requirements

The chemical composition of beeswax makes it susceptible to contamination, which dictates the type of equipment that can be used. This is the most common pitfall for new processors.

The Problem with Reactive Metals

Beeswax will react adversely with certain metals, particularly iron and zinc. This contact can cause discoloration and negatively alter the chemical properties of the wax, reducing its market value.

The Stainless Steel Standard

To avoid contamination, all containers and equipment used for melting, filtering, and storage must be made of a non-reactive material. Stainless steel is the industry standard and the only appropriate metal for this purpose.

Packaging for Market

Once the beeswax is rendered and cooled into blocks, it is typically prepared for bulk shipment. It is often shipped as unwrapped lumps packaged in Hessian bags, a breathable and durable material suitable for transport.

Key Considerations for Your Processing Setup

Your approach will depend on your scale and desired quality.

- If your primary focus is small-scale or hobbyist production: A solar melter offers a simple and cost-effective method for rendering clean wax.

- If your primary focus is consistent, commercial-grade quality: Investing in stainless steel double boilers and dedicated filtration equipment is essential to prevent contamination and produce a premium product.

Ultimately, proper rendering and handling are what preserve the natural quality of the beeswax for its final use.

Summary Table:

| Processing Step | Key Action | Purpose |

|---|---|---|

| Rendering | Melt the raw comb using gentle heat (e.g., double boiler, solar melter). | Separates pure wax from honey, pollen, and debris. |

| Filtration | Filter the liquid wax through a fine mesh or cloth. | Removes all remaining physical impurities for a clean product. |

| Handling | Use only stainless steel equipment for melting and storage. | Prevents chemical contamination from reactive metals like iron or zinc. |

| Packaging | Mold into blocks and pack in breathable Hessian bags for shipment. | Prepares the pure, stable wax for bulk transport to market. |

Produce High-Quality Beeswax Efficiently with the Right Equipment

For commercial apiaries and beekeeping equipment distributors, the quality of your final beeswax product depends on the purity of your processing. Contamination from improper equipment can significantly reduce its market value.

HONESTBEE supplies the durable, non-reactive stainless steel equipment you need—from melters to filtering tanks—to ensure your beeswax meets the highest commercial standards. Our wholesale-focused operations are designed to support your scale and protect your product's integrity.

Contact HONESTBEE today to discuss your commercial beeswax processing needs and get a quote on reliable, professional-grade equipment.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers