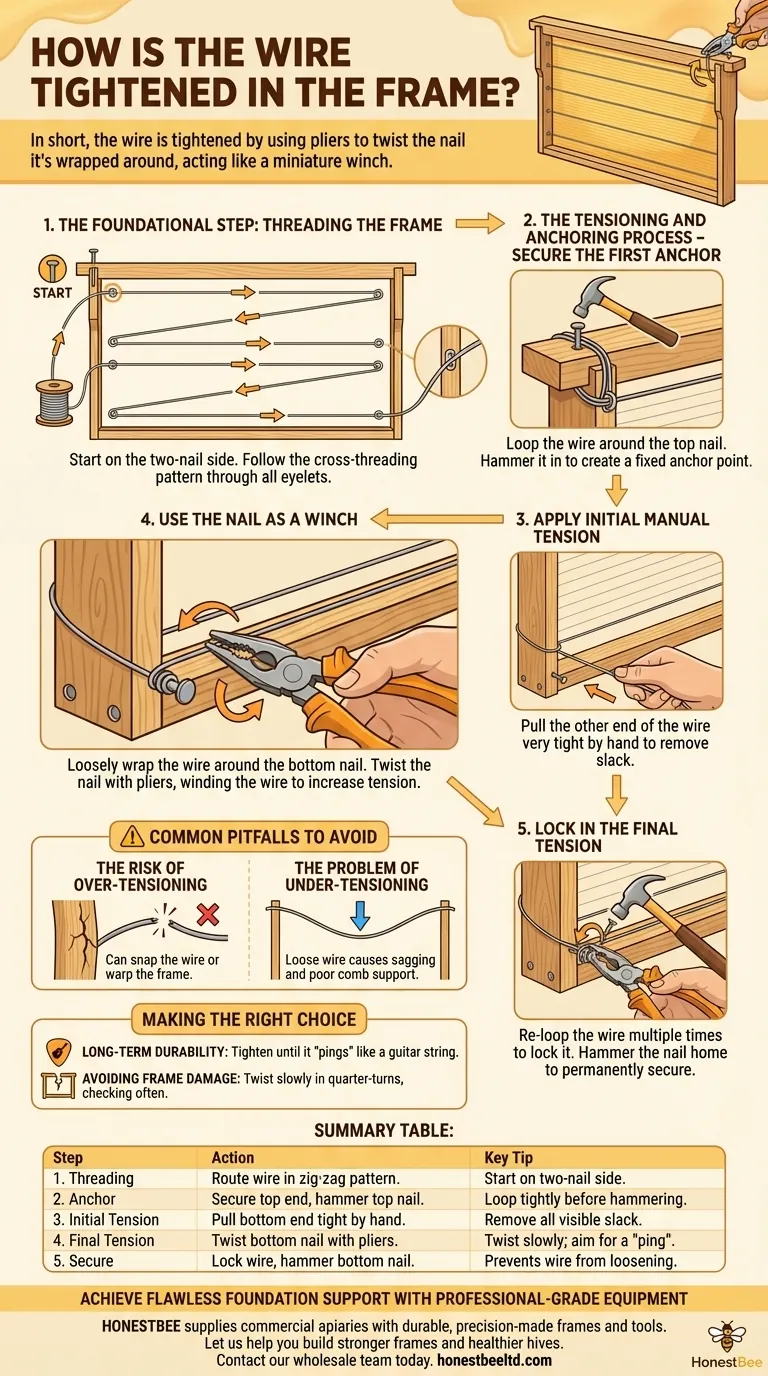

In short, the wire is tightened by using pliers to twist the nail it's wrapped around. This action turns the nail into a miniature winch, pulling the wire taut after it has been threaded through the frame's eyelets and initially pulled tight by hand.

The core principle is not just pulling the wire, but using the leverage of twisting a nail to achieve the final, high tension required. This mechanical advantage is the key to creating a properly taut wire that won't sag.

The Foundational Step: Threading the Frame

Before any tension can be applied, the wire must be correctly routed through the frame to provide even support for the wax foundation.

Start on the Two-Nail Side

The entire process begins on the side of the frame that has two nails, which will serve as your anchor and tensioning points.

Follow the Cross-Threading Pattern

Begin by threading the wire through the first bottom eyelet. Pull it across to the parallel eyelet on the opposite side of the frame.

From there, guide the wire up to the next eyelet on that same side, then pull it back across. This "S" or zig-zag pattern continues until the wire has passed through all eyelets, resulting in four horizontal supports.

The Tensioning and Anchoring Process

With the wire threaded, the next steps involve securing one end and then applying precise tension from the other.

Secure the First Anchor Point

The end of the wire should now be near the top nail. Loop the wire around this top nail several times to get a firm grip.

Hammer the top nail in the rest of the way. This action pinches and secures the wire, creating a fixed anchor point. Any excess wire can be snapped off by bending it back and forth.

Apply Initial Manual Tension

Move to the other end of the wire, which is exiting near the bottom nail. Pull this end very tight by hand to remove all the initial slack from the system.

Use the Nail as a Winch

While holding the tension, loosely wrap the wire around the bottom nail. Now, grip the head of this nail with a pair of pliers.

Begin to twist the nail. As the nail turns, it will wind the wire around its shaft, progressively increasing the tension. This provides the mechanical leverage needed for a truly tight wire.

Lock in the Final Tension

Once the desired tension is reached, re-loop the wire around the nail head multiple times to lock it in place. You can then hammer this nail in completely to permanently secure the wire.

Common Pitfalls to Avoid

Achieving the right tension is a balance. Understanding the potential issues is critical for success and for avoiding damage to your equipment.

The Risk of Over-Tensioning

It is possible to apply too much force. An over-tightened wire can snap during the process or, worse, slowly warp the wooden sidebars of your frame over time, compromising its structure.

The Problem of Under-Tensioning

A loose wire is the most common mistake. If the wire is not taut enough, it cannot properly support the wax foundation, which will lead to sagging, bowing, or warping within the hive.

Making the Right Choice for Your Goal

The final tension should be based on a clear objective for the frame's performance.

- If your primary focus is long-term durability: The wire should be tightened until it "pings" or hums like a low-pitched guitar string when plucked, ensuring the foundation will remain perfectly flat for years.

- If your primary focus is avoiding frame damage: Apply tension by twisting the nail in slow, deliberate quarter-turns, checking the tension frequently to prevent accidental warping or wire breakage.

Mastering this simple mechanical technique transforms a basic wooden frame into a durable and reliable support for your colony's comb.

Summary Table:

| Step | Action | Key Tip |

|---|---|---|

| 1. Threading | Route wire in a zig-zag pattern through all eyelets. | Start on the side with two nails. |

| 2. Anchor | Secure the top end of the wire by hammering the top nail. | Loop wire tightly before hammering. |

| 3. Initial Tension | Pull the bottom end of the wire tight by hand. | Remove all visible slack. |

| 4. Final Tension | Use pliers to twist the bottom nail, winding the wire. | Twist slowly; aim for a 'ping' sound. |

| 5. Secure | Lock the wire and hammer the bottom nail home. | Prevents the wire from loosening. |

Achieve Flawless Foundation Support with Professional-Grade Equipment

Mastering wire tension is crucial, but it starts with a well-made frame. Warped sidebars or poor-quality eyelets can undermine your best efforts.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, precision-made frames and wiring tools through our wholesale-focused operations. We provide the reliable foundation your beekeeping operation depends on.

Let us help you build stronger frames and healthier hives.

Contact our wholesale team today to discuss your equipment needs and volume pricing.

Visual Guide

Related Products

- HONESTBEE Durable Ergonomic Wooden Handle Frame Wire Crimper

- Professional Stainless Steel Pry-Bar Hive Tool

- Multi-Function Plier-Style Frame Grip Hive Tool

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- Heavy-Duty Stainless Steel Frame Grip

People Also Ask

- Why should you avoid using your sink for scrubbing bee frames? Prevent Costly Plumbing Disasters

- Why must new Hive Frames or wax foundations be introduced after TBR? Ensure Colony Health and Honey Purity

- How do Moveable-frame hives and Fixed-comb hives affect honey moisture? Optimize Your Grade A Honey Production

- What frame to use for honeycomb? Choose the Right System for Pure, Edible Comb

- How do standard Langstroth frames improve production efficiency in large-scale queen rearing? Scale Your Queen Production

- What is the purpose of Langstroth beehive frames in beekeeping? Key to Professional Hive Management & Scaling

- What technical advantages do professional brood frame photography systems offer? Precision Data for Apiary Management

- What happens if eggs are allowed to hatch on honey frames? Protect Your Honey Harvest and Hive Health