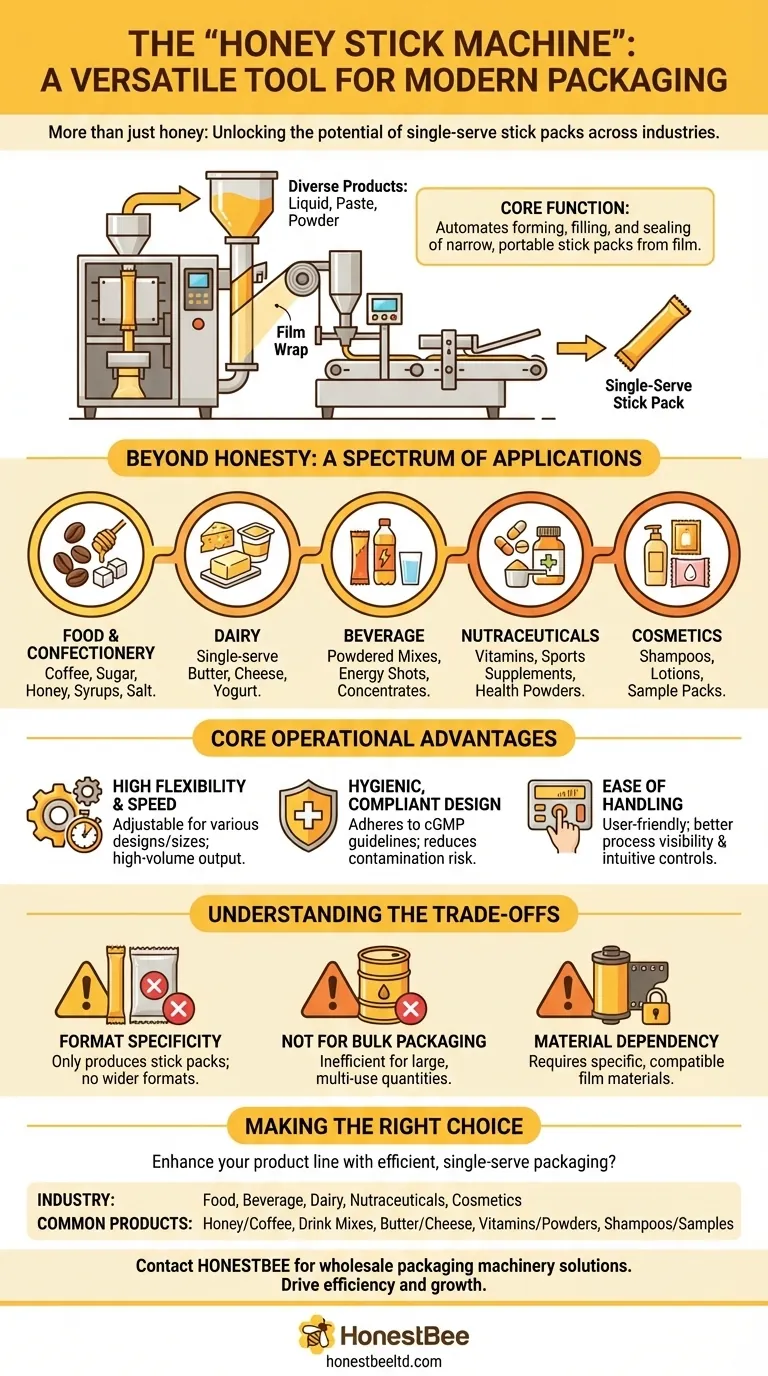

At its core, the "honey stick machine" is not just for honey. This specialized packaging equipment is utilized across the food, dairy, beverage, cosmetic, nutraceutical, and confectionery industries. Its primary function is to package a wide range of products—from energy drinks and coffee to shampoos and sports supplements—into convenient, single-serve stick packs.

The machine's name is misleadingly specific. Its true value lies in its function as a versatile form-fill-seal system designed for creating the narrow, tube-like "stick packs" favored by consumers for their portability and single-serving convenience across numerous sectors.

The Machine Behind the Stick Pack

The term "honey stick machine" refers to a vertical form-fill-seal (VFFS) machine optimized for a particular packaging format. Understanding its core function reveals its broad industrial applicability.

What It Actually Does

A stick pack machine automates the process of wrapping a product inside a film material. It forms a narrow tube, fills it with a precise amount of product, and then seals both ends to create the final "stick."

This format is defined by its high length-to-width ratio, creating a small, portable package that is easy to open and dispense from.

A Spectrum of Applications Beyond Honey

The machine's versatility is its greatest asset. The use of piston and volumetric pumps allows it to handle products of varying viscosities, from thin liquids to thick pastes.

- Food & Confectionery: Honey, flavored syrups, salt, sugar, coffee, and tea.

- Dairy: Single servings of butter, cheese spreads, or yogurt.

- Beverages: Powdered drink mixes and liquid energy drink concentrates.

- Nutraceuticals: Sports supplements, vitamins, and powdered health formulas.

- Cosmetics: Sample-sized or single-use makeup removers, lotions, and shampoos.

Why the Stick Pack Format Is So Effective

The popularity of this packaging is driven by modern consumer behavior. Stick packs are ideal for one-time servings, aligning perfectly with on-the-go lifestyles that demand convenience and portion control.

Core Operational Advantages

Businesses invest in this technology not just for the format, but for the significant operational benefits it provides.

High Flexibility and Speed

These machines are designed to meet changing demands. They can often be adjusted to produce various stick pack designs and sizes, while automation ensures a fast, high-volume output that keeps pace with production needs.

Hygienic, Compliant Design

For the food, cosmetic, and nutraceutical industries, safety is paramount. Stick pack machines are engineered for hygiene, often adhering to cGMP (current Good Manufacturing Practice) guidelines to reduce the risk of contamination during packaging.

Ease of Handling and Operation

Modern designs prioritize user-friendliness. Features that provide better visibility of the packaging process and intuitive controls make the machines easier for operators to handle, monitor, and maintain.

Understanding the Trade-offs

While highly effective, this machine is a specialized tool with clear limitations. Understanding them is key to making a sound investment.

Limitation 1: Format Specificity

The primary trade-off is its lack of versatility in shape. This machine produces only stick packs. It cannot create wider, flatter packages like sachets or stand-up pouches.

Limitation 2: Not for Bulk Packaging

The entire system is optimized for single-serving volumes. It is fundamentally inefficient and inappropriate for packaging larger, multi-use quantities of a product.

Limitation 3: Material Dependency

The machine's performance is tied to the use of specific, compatible film materials that can be properly formed and heat-sealed into a durable tube. Not all packaging films will be suitable.

Making the Right Choice for Your Product

To determine if this technology fits your goals, consider your primary objective.

- If your primary focus is targeting on-the-go consumers: The single-serve, portable stick pack is one of the most effective formats available.

- If your primary focus is packaging diverse liquid, paste, or powder products: This machine's flexibility with different pump systems makes it a strong candidate for a wide range of product types.

- If your primary focus is creating sample-sizes or trial packs: The low material usage and precise portioning of stick packs make them an ideal choice for product sampling campaigns.

- If your primary focus is bulk or multi-serving packaging: You should seek out entirely different packaging solutions, such as pouch fillers or bottling lines.

Ultimately, the "honey stick machine" is a strategic tool for any brand aiming to capture the modern consumer's demand for convenience, portability, and precision.

Summary Table:

| Industry | Common Products Packaged |

|---|---|

| Food & Confectionery | Honey, syrups, coffee, salt, sugar |

| Beverage | Powdered drink mixes, energy shots |

| Dairy | Single-serve butter, cheese spreads |

| Nutraceuticals | Vitamins, sports supplements, health powders |

| Cosmetics | Shampoos, lotions, makeup removers (samples/single-use) |

Ready to enhance your product line with efficient, single-serve stick pack packaging?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality packaging machinery they need to succeed. A honey stick machine can help you meet modern consumer demand for convenience and precision, boosting your brand's appeal.

Contact our experts today to discuss how our wholesale-focused solutions can drive your packaging efficiency and growth.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- How do industrial honey filling machines assist producers in remaining competitive? Beat Imports with Precision

- What are the disadvantages of volumetric filling machines? Key Drawbacks for Your Packaging Line

- What are the primary benefits of automated honey-filling machines? Scale Your Commercial Apiary Efficiency

- How do automated honey-filling machines assist apiaries in achieving product differentiation for economic feasibility?

- What material should a honey-filling machine be made from? Ensure Safety with Food-Grade Stainless Steel

- What advantages do high-precision honey filling machines provide? Optimize Yield and Preserve Botanical Quality

- What is the importance of automated honey-filling machines? Boost Efficiency and Safety in Your Supply Chain

- How do automated honey filling machines improve efficiency? Scale Your Production with Precision and Speed