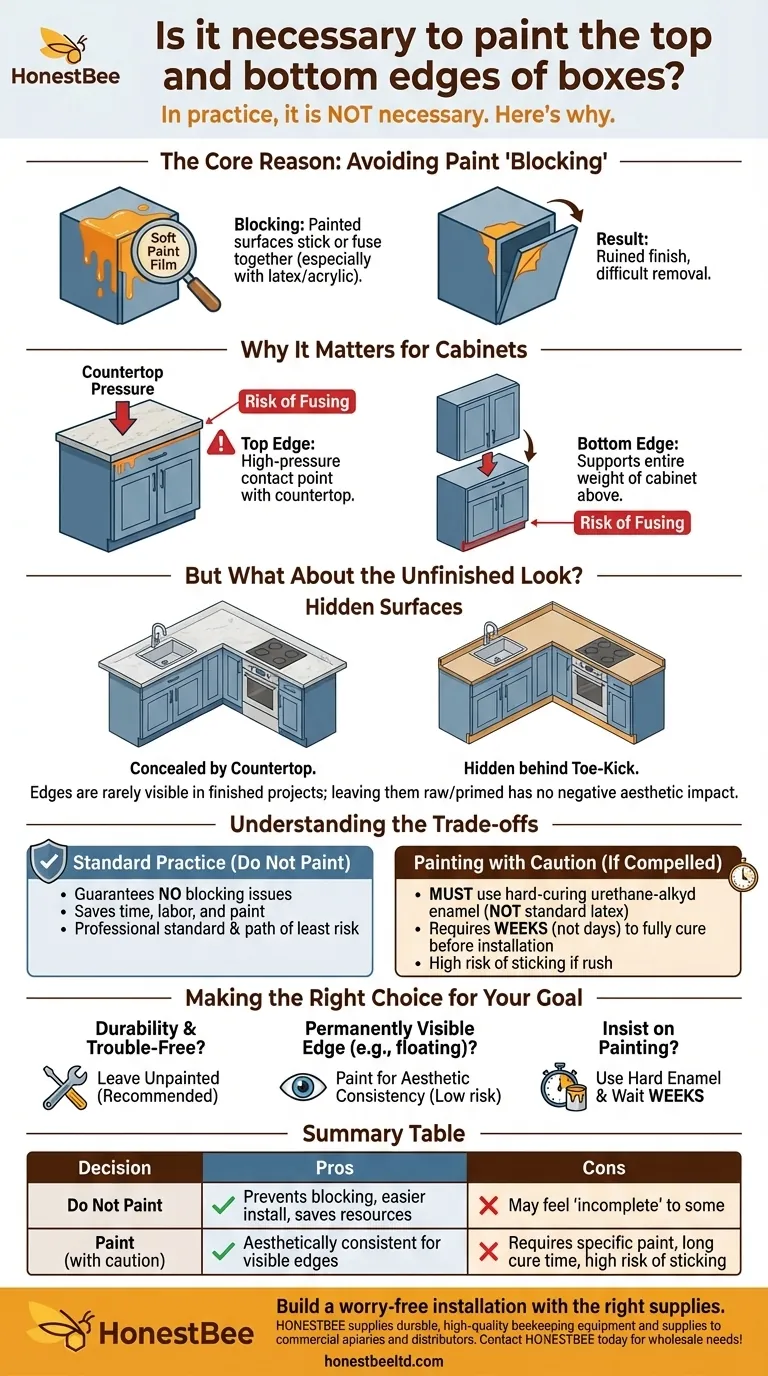

In practice, it is not necessary to paint the top and bottom edges of cabinet boxes. This is the standard approach for professional cabinet installers and painters. The primary reason is functional: painted surfaces can stick to each other under pressure, a phenomenon known as "blocking," which can cause issues when cabinets are stacked or when countertops are installed.

The decision to paint cabinet box edges is not about right versus wrong, but about prioritizing function over form. Forgoing paint on these unseen, high-contact surfaces is the safer, more practical choice that prevents future problems without compromising aesthetics.

The Core Reason: Avoiding Paint 'Blocking'

What is Blocking?

"Blocking" is the technical term for when two painted surfaces stick or fuse together. This happens most often with latex and acrylic paints, which can remain slightly tacky for weeks or even months as they fully cure.

When pressure or heat is applied, this soft paint film can create a bond. Pulling the surfaces apart can peel the paint off one or both sides, ruining the finish.

Why It Matters for Cabinets

The top and bottom edges of cabinet boxes are high-pressure contact points. Base cabinets have thousands of pounds of countertop pressing down on their top edges. Upper cabinets rest their entire weight on the bottom edge of the cabinet above them in a stack.

Painting these edges creates a significant risk of the cabinet fusing to the countertop or to an adjacent cabinet, making future removal or adjustments extremely difficult and destructive.

But What About the Unfinished Look?

Hidden Surfaces

A key reason it is safe to skip painting these edges is that they are almost never visible in a finished kitchen or built-in.

The top edges of base cabinets are completely concealed by the countertop overhang.

Concealed by Design

The bottom edges of upper cabinets are only visible if you are looking straight up at them from below. Similarly, the bottom edges of base cabinets are hidden behind the toe-kick trim.

Because these surfaces are out of sight, leaving them as raw or primed wood has no negative impact on the final look of the project.

Understanding the Trade-offs

The Case for Not Painting (Standard Practice)

The arguments for leaving the edges unpainted are purely functional. This approach guarantees you will avoid any issues with blocking.

It also saves a small amount of time, labor, and paint. In a large project, this efficiency adds up. This is the professional standard for good reason: it is the path of least risk.

The Case for Painting (And How to Do It Safely)

Some people feel compelled to paint every surface for a sense of "completeness." If you choose to do this, you must take specific precautions to minimize the risk of blocking.

First, use the right paint. Avoid standard latex wall paint. A high-quality urethane-alkyd enamel is a much better choice, as it cures to a harder, less tacky film.

Second, allow for maximum cure time. Do not install the cabinets just because the paint is dry to the touch. Wait as long as possible—ideally weeks, not days—to allow the paint to harden completely before stacking cabinets or installing countertops.

Making the Right Choice for Your Goal

- If your primary focus is durability and a trouble-free installation: Leave the top and bottom edges of the cabinet boxes unpainted.

- If the cabinet edges will be permanently visible (e.g., an open-style floating cabinet): Paint the edges for aesthetic consistency, as the risk of blocking is low without a connecting surface.

- If you insist on a fully painted box for personal preference: Use a hard-curing enamel paint and wait several weeks for it to fully cure before subjecting the edges to pressure.

Ultimately, choosing not to paint these hidden surfaces is a sign of an informed decision, prioritizing long-term function over unnecessary labor.

Summary Table:

| Decision | Pros | Cons |

|---|---|---|

| Do Not Paint | Prevents paint 'blocking', easier installation, saves time & materials | May feel 'incomplete' to some |

| Paint (with caution) | Aesthetically consistent for visible edges | Requires specific paint & long cure time, high risk of sticking |

Build a worry-free installation with the right supplies. HONESTBEE supplies durable, high-quality beekeeping equipment and supplies to commercial apiaries and distributors through wholesale-focused operations. Our products are designed for professionals who value long-term performance and reliability. Let us help you equip your operation for success. Contact HONESTBEE today to discuss your wholesale needs!

Visual Guide

Related Products

- Beehive Entrance Discs Plastic Bee Entrance Disc for Bee Hives

- Multi-Functional Sliding Hive Entrance for Beekeeping

- Metal Hive Feet Bee Hive Stand for Ant Protection

- Metal Bee Hive Stand Bee Box Stand for Beekeeping

- Plastic Bee Hive Stand for Beekeeping

People Also Ask

- What does a fully closed setting on a round beehive entrance disc indicate? A Guide to Hive Security

- How does the orientation of a beehive entrance toward the south impact colony productivity? Boost Your Honey Yield

- What is required to be a beekeeper? Essential Equipment, Knowledge & Mindset

- Why is it important to adjust beehive entrances throughout the season? Optimize Colony Defense and Ventilation

- What is the function of a steel entrance disc on a beehive? Master Traffic Control & Colony Protection