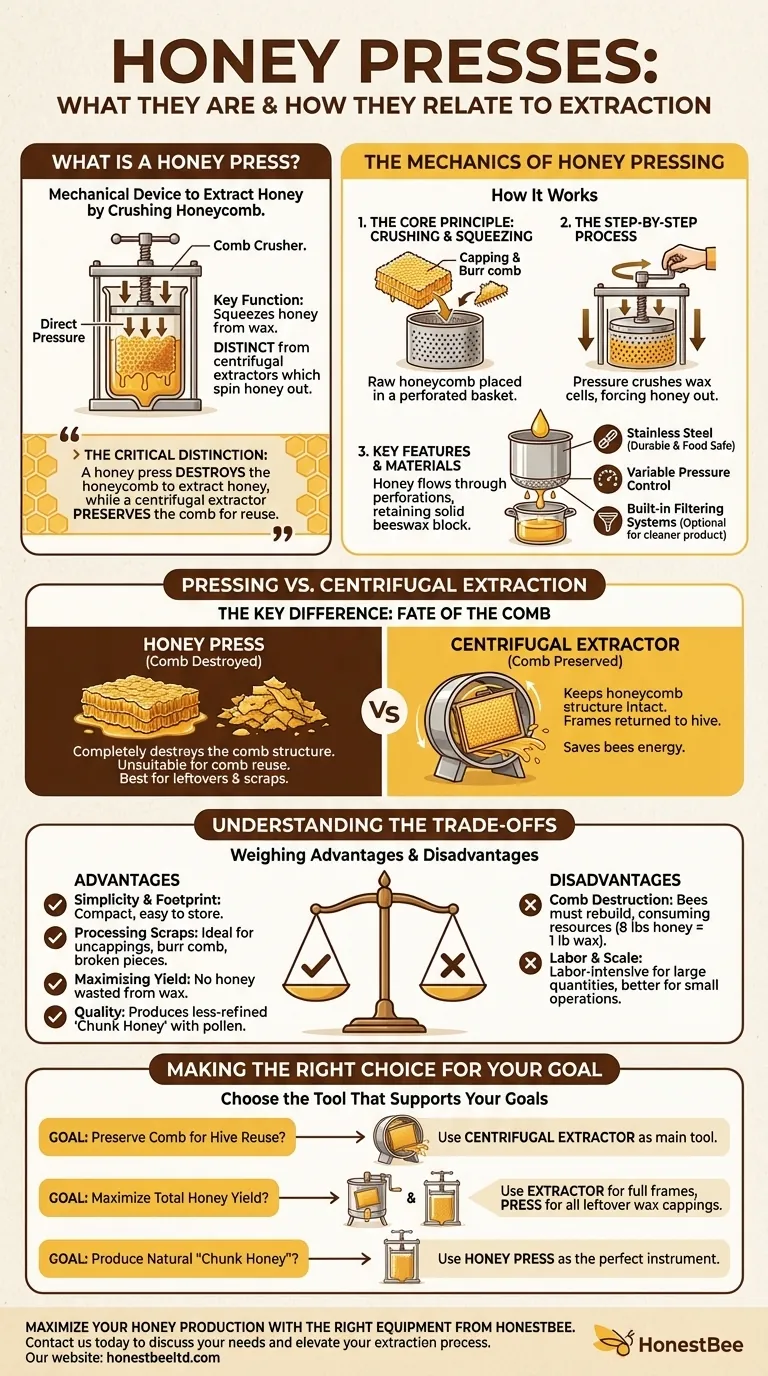

In short, a honey press is a mechanical device that extracts honey by crushing the honeycomb. It functions as a "comb crusher," using direct pressure to squeeze honey from the wax. This is a distinct method of extraction compared to centrifugal extractors, which use spinning force to sling honey out of the comb cells.

The critical distinction is this: a honey press destroys the honeycomb to extract the honey, while a centrifugal extractor preserves the comb for the bees to reuse. This single difference defines its primary use cases and trade-offs.

The Mechanics of Honey Pressing

A honey press operates on the simple principle of compression. By understanding its components and process, you can see how it fits into honey processing.

The Core Principle: Crushing and Squeezing

At its heart, a honey press is a simple machine. Raw honeycomb, including wax cappings and burr comb, is placed inside a perforated container. A plate is then screwed down, applying immense pressure to the mass.

This pressure crushes the wax cells, forcing the liquid honey to flow out through the perforations while retaining the solid beeswax.

The Step-by-Step Process

The operation is straightforward. The user places the raw comb into the press basket. They then rotate a handle or crank, which drives a pressing plate downward.

As the plate compresses the comb, honey drips out of the bottom of the basket into a collection container. The remaining compressed block of beeswax is removed afterward.

Key Features and Materials

Most honey presses are made of stainless steel for durability and food safety. Many models offer variable pressure control, allowing the user to adjust the force based on the type of comb.

Some advanced presses even include built-in filtering systems to separate impurities from the honey as it is being extracted, resulting in a cleaner final product.

Pressing vs. Centrifugal Extraction: The Key Difference

While both are tools for extraction, the choice between a press and a centrifugal extractor comes down to your goals for the comb and the type of honey you wish to produce.

The Fate of the Comb

This is the most significant point of differentiation. A centrifugal extractor keeps the honeycomb structure intact. The frames can be returned to the hive, saving the bees the immense energy required to build new wax comb.

A honey press, by its very nature, completely destroys the comb. This makes it unsuitable for beekeepers who want to reuse their drawn-out frames.

Maximizing Your Total Yield

Where a press excels is in processing the leftovers from a primary extraction. It can easily handle uncappings, burr comb, and broken pieces of comb that cannot be put into a centrifugal extractor.

Using a press on these wax scraps ensures that no honey is wasted, significantly increasing your total yield from a harvest.

The Quality of the Honey

A press produces what is often called chunk honey. Enthusiasts of this style appreciate its less-refined character and natural taste.

Because the process involves crushing, more pollen and fine wax particles can be incorporated into the honey, which some consumers find more desirable.

Understanding the Trade-offs

Choosing a honey press involves weighing its distinct advantages against its fundamental limitations. It is not a universally superior tool, but rather a specialized one.

Advantage: Simplicity and Footprint

Honey presses are typically compact, mechanically simple, and easy to store. They are an excellent choice for hobbyists with limited space or a small number of hives.

Advantage: Processing Scraps

A press is the ideal tool for wringing every last drop of honey out of wax cappings and other comb fragments that are otherwise difficult to process.

Disadvantage: Comb Destruction

The primary drawback is the destruction of the comb. Bees expend significant resources (consuming about 8 pounds of honey to produce 1 pound of wax) to build comb. Destroying it means they must start over, which can reduce the next season's honey surplus.

Disadvantage: Labor and Scale

While simple, pressing can be a labor-intensive process for larger quantities of honey compared to a motorized centrifugal extractor. It is best suited for small-scale operations.

Making the Right Choice for Your Goal

Ultimately, the honey press is a valuable piece of equipment when used for the right task. It is often used in conjunction with an extractor, not as a replacement for it.

- If your primary focus is preserving comb for hive reuse: A centrifugal extractor should be your main tool, reserving the press for cappings and scraps.

- If your primary focus is maximizing total honey yield: Use an extractor for full frames and a press to process all the leftover wax cappings.

- If your primary focus is producing natural "chunk honey" for a niche market: A honey press is the perfect instrument for this specific goal.

Choose the tool that directly supports your beekeeping philosophy and operational goals.

Summary Table:

| Feature | Honey Press | Centrifugal Extractor |

|---|---|---|

| Method | Crushes and squeezes comb | Spins honey out of comb |

| Comb Fate | Destroyed | Preserved for reuse |

| Best For | Cappings, scraps, chunk honey | Full frames, comb preservation |

| Scale | Small-scale, hobbyist | Small to large-scale |

Maximize your honey production with the right equipment from HONESTBEE.

Whether you're a commercial apiary focused on yield or a distributor supplying beekeepers, choosing the correct extraction tools is critical for efficiency and profitability. Our wholesale-focused operations provide durable, food-grade honey presses and centrifugal extractors to meet your specific operational goals.

Let our experts help you select the perfect equipment to process full frames and maximize yield from every scrap of wax. Contact HONESTBEE today to discuss your needs and elevate your honey extraction process.

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the crush and strain method for extracting honey? A Simple Guide to Low-Cost Honey Harvesting

- How does a honey press function? Expert Insights into Traditional Extraction & Waste Reduction

- What are the benefits of using a honey press for Warré or Top Bar beehives? Maximize Your Natural Harvest

- How is the honey press cleaned and maintained? Essential Tips for Longevity and Hygiene

- What are the advantages of using a honey press? Affordable, Versatile Harvesting for Small-Scale Beekeepers

- What is the advantage of pressing and bottling honey one comb at a time? Unlock Unique Artisan Flavor Profiles

- How does the operational speed of the extruder affect the performance of a Wax Screw Press? Precision vs. Volume

- What are the operational advantages of a manual Honey Presser? Increase Yield by 17% Over Hand-Squeezing