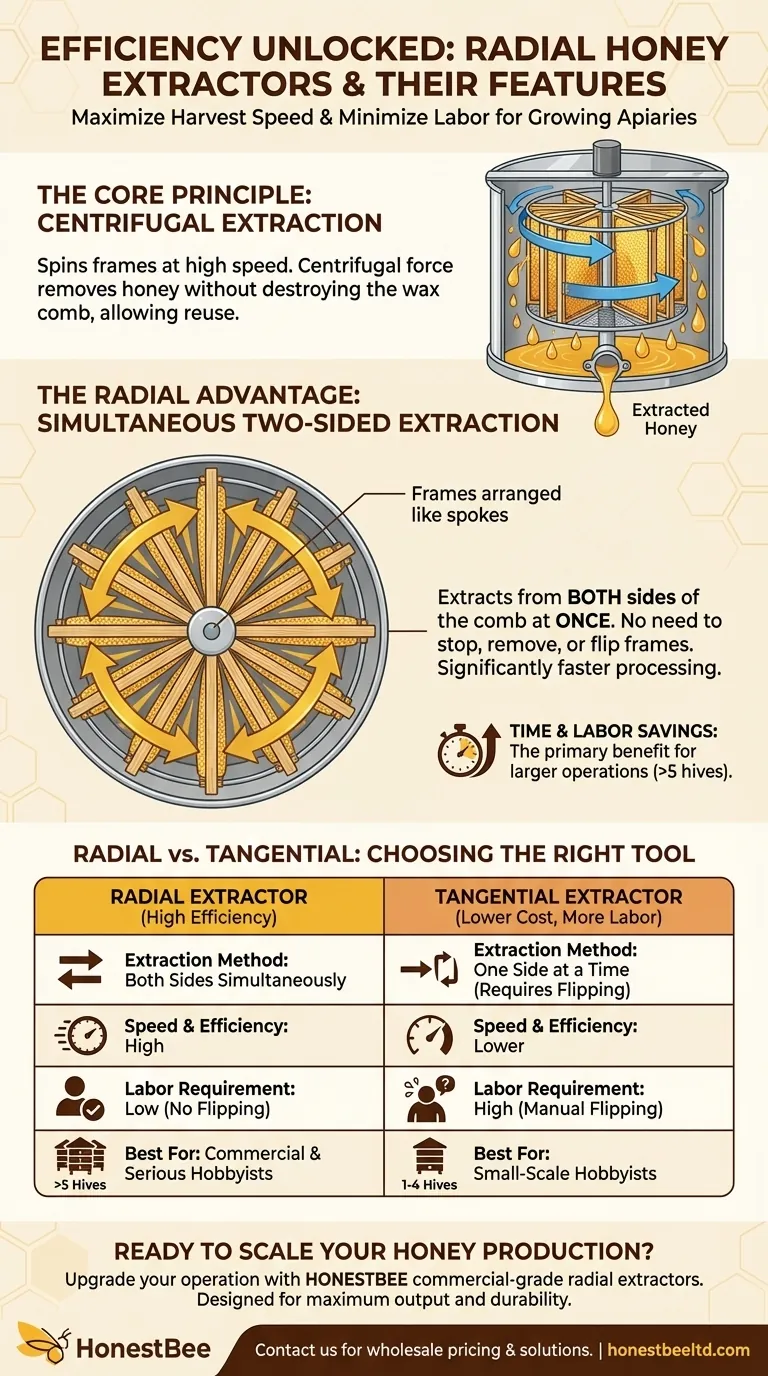

A radial honey extractor is a mechanical device that uses centrifugal force to remove honey from both sides of a honeycomb frame simultaneously. By arranging frames like spokes in a wheel, it offers a significant speed and efficiency advantage over other designs, making it a popular choice for beekeepers with more than a few hives.

The fundamental advantage of a radial extractor is its ability to save time and labor. By extracting honey from both sides of the comb at once, it completely eliminates the need to stop the process, remove the frames, and flip them over.

The Core Principle: Centrifugal Extraction

How It Works

A honey extractor consists of a large drum, typically made of stainless steel or plastic, that holds a basket for the honeycomb frames.

When this basket spins at high speed, it generates a powerful centrifugal force.

The Goal of Extraction

This force flings the liquid honey out of the wax cells and onto the inner wall of the drum. The key is that this process removes the honey without destroying the delicate wax comb.

The extracted honey then drains to the bottom of the drum, where it can be collected. The intact combs can be returned to the hive for the bees to refill, saving them enormous time and energy.

The Defining Feature of a Radial Extractor

Simultaneous, Two-Sided Extraction

The defining characteristic of a radial extractor is how it positions the frames. The frames stand vertically in the basket with the top bar of each frame facing the outside of the drum.

This "spokes on a wheel" arrangement means that as the basket spins, the centrifugal force pulls honey from both sides of the comb at the same time.

The Benefit of Speed and Efficiency

This simultaneous extraction is the machine's primary advantage. It dramatically reduces the total time required to process a batch of honey.

Eliminating Manual Labor

Unlike other designs, there is no need to stop the machine mid-cycle to flip the frames. This single feature is the main reason radial extractors are favored for larger operations, as it significantly reduces manual handling and oversight.

Understanding the Trade-offs

The Tangential Alternative

The primary alternative is a tangential extractor. This design places the frame flat against the side of the basket, exposing only one side of the comb to the centrifugal force at a time.

To extract all the honey, the beekeeper must stop the machine, flip each frame manually, and then run the cycle again.

The Scale and Cost Factor

Because they extract from only one side, tangential extractors are slower and more labor-intensive. However, their simpler design often makes them smaller and less expensive.

Radial extractors are generally larger to accommodate their frame orientation and are typically preferred by commercial beekeepers or serious hobbyists for whom time savings are critical.

Power Options

Both radial and tangential extractors are available in manual (hand-crank) and electric (motorized) models. Motorized versions provide consistent speed and are easier to operate, making them ideal for processing large quantities of honey.

Making the Right Choice for Your Apiary

Choosing an extractor depends entirely on the scale of your beekeeping operation.

- If your primary focus is efficiency and time savings (more than 5 hives): The radial extractor is the superior choice, as it will dramatically reduce your processing time and labor.

- If your primary focus is a small-scale hobby (1-4 hives): A simpler and more affordable tangential extractor is often the most practical solution.

Ultimately, selecting the right tool for the scale of your work ensures an efficient and rewarding honey harvest.

Summary Table:

| Feature | Radial Extractor | Tangential Extractor |

|---|---|---|

| Extraction Method | Both sides of the comb simultaneously | One side at a time (requires flipping) |

| Speed & Efficiency | High | Lower |

| Labor Requirement | Low (no frame flipping) | High (manual frame flipping) |

| Best For | Commercial apiaries & serious hobbyists (>5 hives) | Small-scale hobbyists (1-4 hives) |

| Typical Cost | Higher | Lower & more affordable |

Ready to Scale Your Honey Production?

Upgrade your operation with a high-efficiency radial extractor from HONESTBEE. We supply durable, commercial-grade beekeeping equipment to serious apiarists and distributors. Our radial extractors are designed to maximize your harvest output while minimizing manual labor.

Contact HONESTBEE today to discuss wholesale pricing and find the perfect extraction solution for your commercial apiary.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What factors should be considered when choosing between an electric and manual honey extractor?

- What are the characteristics of motors used in honey extractors? Ensure Efficient, Damage-Free Honey Harvesting

- What is the purpose of decanting in honey extraction? Achieve a Purer, More Stable Honey Product

- What are some safety tips for using electric honey extractors? Ensure a Smooth, Hazard-Free Harvest