Preserving honeycomb integrity is paramount for the health and productivity of a bee colony. Bees expend enormous energy to build wax comb, and destroying it forces them to divert resources from honey production to rebuilding. Automated extractors help by using controlled, consistent centrifugal force to remove honey, significantly minimizing the structural damage that can occur with less precise manual methods.

The core decision a beekeeper makes about honey extraction is not just about speed or efficiency. It's an investment choice: either invest your bees' energy in rebuilding comb year after year, or invest in equipment that preserves this vital resource, leading to healthier hives and greater honey yields over the long term.

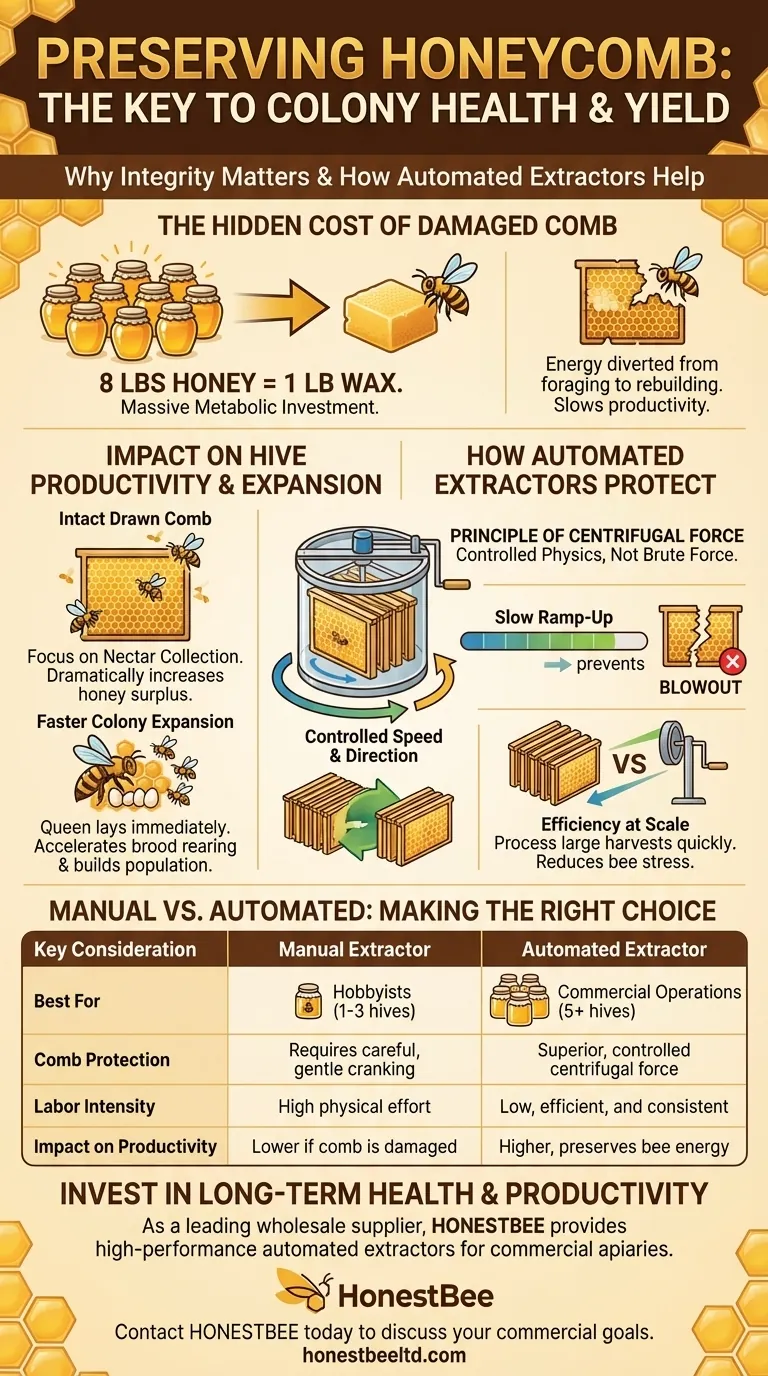

The Hidden Cost of Damaged Comb

Before a single drop of honey is stored, bees must first build the container. Understanding the true cost of this construction is key to appreciating why preserving the comb is so critical.

An Enormous Energy Investment

Bees must consume approximately eight pounds of honey to produce just one pound of wax. This 8:1 ratio represents a massive metabolic investment for the colony.

When honeycomb is destroyed during extraction, the bees are forced to consume a significant portion of their own food stores just to rebuild their home and pantry.

The Impact on Hive Productivity

Every hour a bee spends producing wax is an hour it is not foraging for nectar. By providing bees with intact, drawn-out comb to refill, you are giving them a critical head start.

This allows the colony to dedicate its workforce almost exclusively to nectar collection, dramatically increasing the potential honey surplus for the beekeeper.

Faster Colony Expansion

Drawn comb is not just for honey; it's also where the queen lays her eggs. When empty frames are available, the queen can begin laying immediately.

This accelerates brood rearing and allows the colony to build its population much faster, leading to a stronger, more resilient hive.

How Automated Extractors Protect the Comb

Automated extractors are specifically engineered to solve the problem of comb damage. They replace brute force with controlled physics to achieve a clean and safe extraction.

The Principle of Centrifugal Force

Like all extractors, automated models place honey-filled frames in a drum and spin them. This rotation generates centrifugal force, which flings the honey outwards against the wall of the drum, where it drips down for collection.

Controlled Speed and Direction

The key advantage of an automated system is its electric motor and controller. The operator can program a gradual ramp-up in speed, which is crucial.

Starting slowly allows some honey to be extracted from both sides of the frame, balancing the weight. A sudden, high-speed spin on a heavy, full frame can cause the delicate comb to detach from its foundation—an event known as a "blowout." Many automated models also reverse direction automatically to ensure even extraction.

Efficiency at Scale

For beekeepers with more than a few hives, the speed and consistency of an automated extractor are essential. The process is repeatable and far less labor-intensive than manual cranking.

This efficiency allows a beekeeper to process a large harvest quickly, minimizing the time frames are out of the hive and reducing stress on the bees.

Understanding the Trade-offs

While beneficial, automated extractors are not the only solution, and they come with their own set of considerations.

Manual vs. Automated

Manual, hand-crank extractors are an excellent, lower-cost option for beginners with only one or two hives. However, they require significant physical effort and a careful touch to avoid damaging the comb by cranking too hard or too fast.

Automated extractors require a significant upfront financial investment but provide superior control, speed, and consistency that protects the comb and saves labor in the long run.

The Unavoidable Risk of "Blowouts"

Even with an automated extractor, comb damage can still occur. This is most common with freshly drawn, "new" wax, which is more fragile than older, darker comb.

Operating the extractor on a hot day (when wax is softer) or setting the spin cycle to ramp up too quickly can still result in blowouts. Careful operation is always required.

Tangential vs. Radial Design

Automated extractors come in two main types. Tangential extractors hold frames like spokes in a wheel, extracting from one side at a time, requiring you to flip the frames midway. Radial extractors hold frames with the top bar facing outward, extracting from both sides simultaneously due to the angle.

Radial extractors are generally more efficient and gentler on the comb, making them the preferred choice for serious and commercial operations.

Making the Right Choice for Your Goal

Your extraction method should align directly with your beekeeping objectives and scale.

- If your primary focus is hobby beekeeping with 1-3 hives: A manual extractor is a cost-effective starting point, but focus on careful, gentle cranking to preserve your bees' hard work.

- If your primary focus is maximizing honey yield and colony health: An automated radial extractor is the superior long-term investment, as it best protects the comb that drives hive productivity.

- If your primary focus is scaling an operation to 5+ hives: An automated extractor becomes a necessary tool for managing the workload efficiently and ensuring the consistent preservation of your most valuable asset: drawn comb.

Ultimately, choosing the right extraction method is a direct investment in the long-term health and productivity of your hives.

Summary Table:

| Key Consideration | Manual Extractor | Automated Extractor |

|---|---|---|

| Best For | Hobbyists (1-3 hives) | Commercial Operations (5+ hives) |

| Comb Protection | Requires careful, gentle cranking | Superior, controlled centrifugal force |

| Labor Intensity | High physical effort | Low, efficient, and consistent |

| Upfront Cost | Lower | Higher, but a long-term investment |

| Impact on Hive Productivity | Lower if comb is damaged | Higher, preserves bee energy for honey production |

Ready to invest in the long-term health and productivity of your apiary?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance automated extractors you need to protect your valuable drawn comb and maximize honey yields. Our equipment is designed for the demands of a growing operation, saving you labor and supporting stronger, healthier hives.

Contact HONESTBEE today to discuss the best extraction solution for your commercial beekeeping goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- What happens during the spinning process in honey extraction? Efficiently Harvest Honey & Preserve Comb

- What are the main types of honey extractors? Choose the Right Extractor for Your Apiary

- What is the main difference between an electric and a manual honey extractor? Choose the Right Tool for Your Apiary's Scale

- Why is a centrifugal honey extractor considered core equipment? Boost Your API's Efficiency and Yield

- How does a Centrifugal Honey Extractor contribute to the efficiency of the honey harvesting process? Maximize Your Yield

- What is the importance of using a high-power stainless steel honey extractor? Boost Professional Apiary Efficiency

- How does a radial honey extractor work? Maximize Your Harvest Efficiency with Simultaneous Two-Sided Extraction

- What precaution should be taken regarding the location when extracting honey and why? Ensure a Safe & Bee-Free Harvest