To prevent fermentation in high-moisture honey, you must either reduce the moisture content below the critical threshold or halt the fermentation process entirely. The most effective methods are using temperature regulation tools like bucket heaters and dehumidifiers to evaporate excess water or freezing the honey immediately after harvest to stop yeast activity.

The fundamental challenge is that honey with a moisture content above 19% provides a fertile ground for yeast to thrive, leading to fermentation. Your primary goal is not just to treat the symptom, but to control the underlying condition: excess moisture.

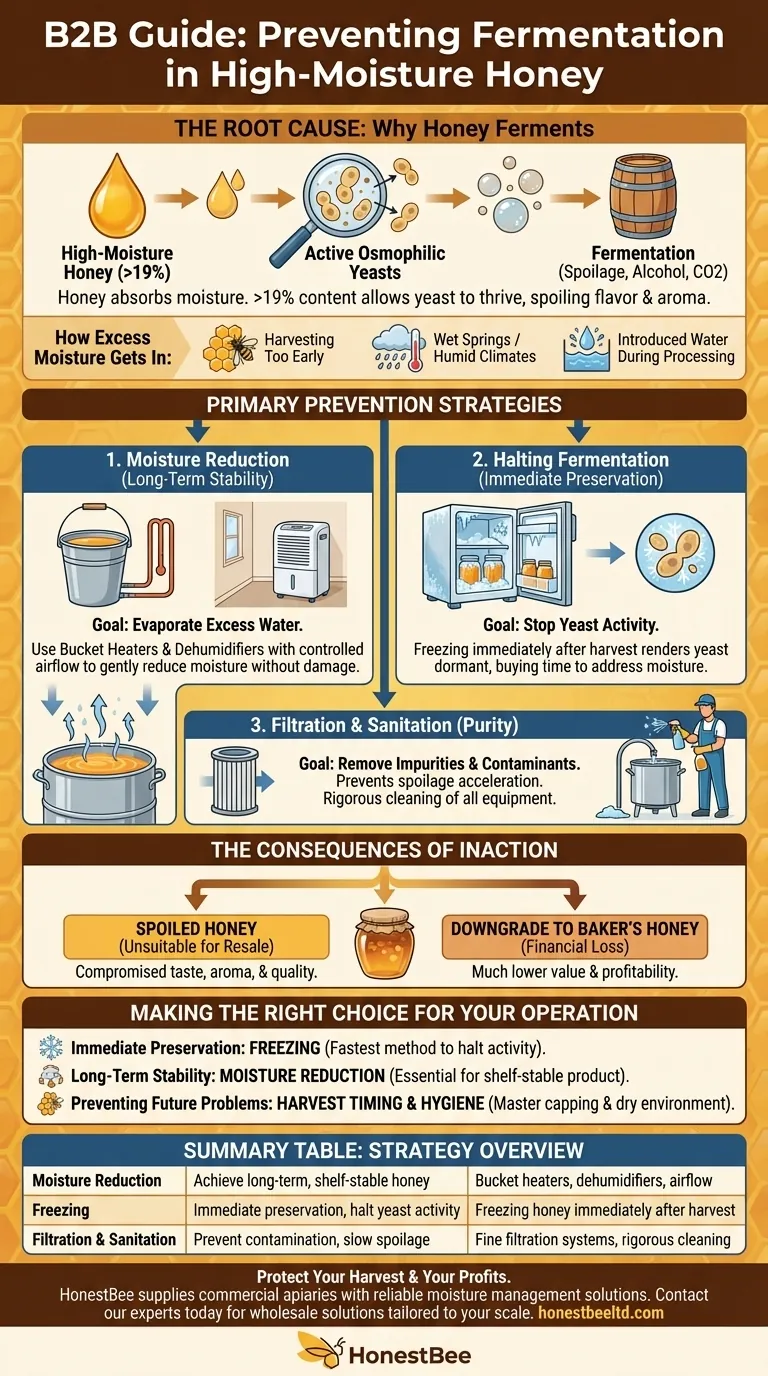

The Root Cause: Why Honey Ferments

Understanding the "why" behind fermentation is the first step toward effective prevention. Honey is naturally resistant to spoilage due to its low water content and high sugar concentration, but this balance is fragile.

The Critical Moisture Threshold

Honey is considered hygroscopic, meaning it can absorb moisture from the air. When its moisture content rises, typically above 19%, the naturally present osmophilic yeasts can begin to multiply and metabolize the sugars.

This metabolic process produces alcohol and carbon dioxide, which spoils the honey's flavor, aroma, and overall quality.

How Excess Moisture Gets In

Several factors can lead to dangerously high moisture levels in your honey.

These include harvesting honey too early before the bees have had a chance to dehydrate it and cap the cells. Environmental factors like wet springs or humid climates also play a significant role, as does accidentally introducing water during the extraction and bottling process.

Primary Prevention Strategies

Once you understand the cause, the solutions become clear. The strategy revolves around removing excess moisture or creating an environment where yeast cannot function.

Moisture Reduction with Heat and Airflow

A direct and effective method is to create an environment that encourages evaporation.

Using tools like bucket heaters to gently warm the honey, combined with a dehumidifier in a small, enclosed room, can effectively reduce the moisture content. This process carefully removes water without damaging the honey's delicate qualities.

Halting Fermentation with Freezing

If you cannot reduce moisture immediately, freezing is an excellent way to preserve the honey.

Freezing the honey right after harvesting does not kill the yeast, but it renders it dormant. This completely halts the fermentation process, buying you time to address the moisture issue later.

Ensuring Purity Through Filtration

While moisture is the primary culprit, contaminants can accelerate spoilage.

Implementing filtration systems helps remove impurities and foreign particles. Maintaining scrupulous sanitation by wiping down and sanitizing all equipment, from the extractor to the bottling machine, minimizes the introduction of unwanted microbes.

The Consequences of Inaction

Failing to manage moisture content has significant and often irreversible consequences for your product and your business.

Impact on Quality and Resale Value

Fermented honey is considered spoiled and is unsuitable for resale as consumable table honey. The taste and aroma are compromised, and the product's quality is significantly reduced.

The Downgrade to Baker's Honey

Once honey has fermented, its only potential use is often as baker's honey. This is a much lower-grade classification, which commands a significantly lower price and represents a substantial financial loss.

Making the Right Choice for Your Operation

Your strategy for preventing fermentation should align with your operational capabilities and long-term goals.

- If your primary focus is immediate preservation: Freezing is the fastest and most reliable method to halt all yeast activity right after a potentially wet harvest.

- If your primary focus is long-term stability for sale: Actively reducing moisture with gentle heat and dehumidifiers is essential to produce a shelf-stable product that meets quality standards.

- If your primary focus is preventing future problems: Master the art of timing your harvest for when honey is fully capped and maintain an impeccably dry and clean extraction environment.

Ultimately, proactive moisture management is the defining factor in protecting the quality and value of your honey.

Summary Table:

| Method | Primary Goal | Key Tools/Process |

|---|---|---|

| Moisture Reduction | Achieve long-term, shelf-stable honey | Bucket heaters, dehumidifiers, controlled airflow |

| Freezing | Immediate preservation, halt yeast activity | Freezing honey immediately after harvest |

| Filtration & Sanitation | Prevent contamination, slow spoilage | Fine filtration systems, rigorous equipment cleaning |

Protect your honey harvest and your profits. Fermentation can downgrade your product to lower-value baker's honey. HONESTBEE supplies commercial apiaries and distributors with the reliable equipment needed for proactive moisture management, including bucket heaters and dehumidifiers. Contact our experts today to discuss wholesale solutions tailored to your operation's scale and ensure the quality of every batch.

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is high-precision temperature regulation essential in equipment used for drying bee-bread? Preserve Your Harvest.

- How to dry up honey? The Safe Guide to Stabilizing Honey and Preventing Fermentation

- What are the negative impacts of excess humidity in honey? Prevent Spoilage and Protect Quality

- What is the recommended drying temperature and moisture content for honey? Preserve Quality & Prevent Fermentation

- What are the advantages of a condensation honey dryer? Boost Quality & Yield for Your Apiary

- What type of tank is used in the honey drying process? Master Gentle Moisture Removal for Premium Honey

- Why is a high-pressure ratio refrigerant, such as R-410a, used in the heat pump cycle of a honey drying system?

- What techniques can be employed to lower the moisture level of honey? Mastering Effective Drying for Quality Harvests