Ultimately, choosing a honey filling machine with good maintenance and support is about ensuring long-term operational viability and protecting your investment. A well-supported machine is easier to clean, maintain, and repair, which directly minimizes costly downtime and guarantees the availability of critical spare parts and expert assistance when you need them most.

Your honey filling machine is not just a piece of equipment; it's the engine of your production line. Prioritizing maintenance and support is the insurance policy that keeps that engine running, protecting your initial investment and ensuring its profitability for years to come.

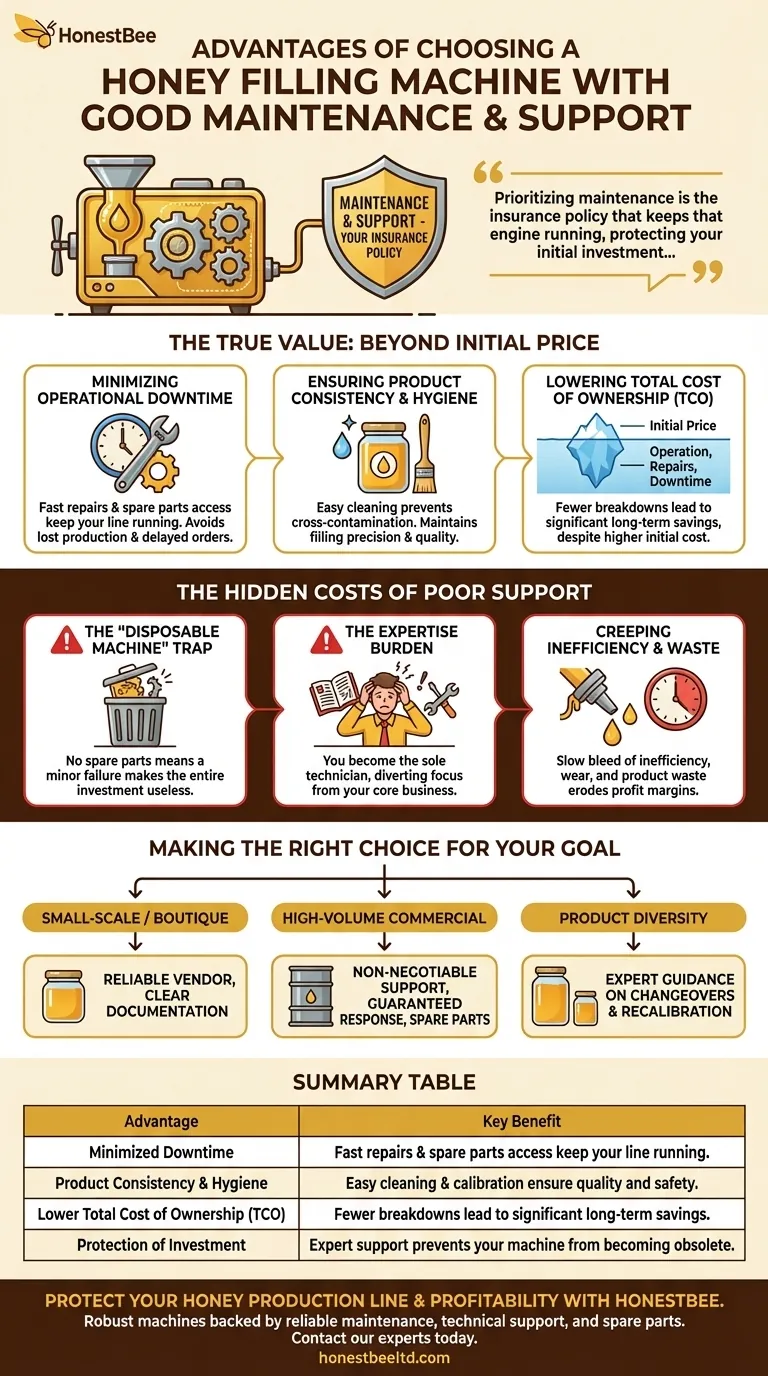

The True Value: Beyond Initial Purchase Price

When investing in a honey filling machine, it's easy to focus on immediate specifications like filling speed or capacity. These are important, but they only tell part of the story.

The machine's long-term performance and reliability are what truly determine its value, and this is where maintenance and support become critical factors.

Minimizing Operational Downtime

Downtime is the silent killer of profitability. Every hour your filling line is stopped due to a malfunction means lost production, delayed orders, and potential damage to your brand's reputation.

Excellent vendor support provides a safety net. Access to knowledgeable technicians and a ready supply of spare parts means a problem that could halt your operation for days can often be solved in a matter of hours.

Ensuring Product Consistency and Hygiene

Honey is a food product, and hygiene is non-negotiable. A machine designed for easy maintenance is also designed for easy and thorough cleaning.

This prevents cross-contamination and ensures your product quality remains consistently high. A well-maintained machine also holds its calibration, ensuring the filling precision you paid for is delivered with every jar, minimizing product waste.

Lowering the Total Cost of Ownership (TCO)

The sticker price of a machine is only its initial cost. The Total Cost of Ownership (TCO) includes the purchase price plus the costs of operation, maintenance, repairs, and downtime over its entire lifespan.

A machine with strong support may have a higher initial price, but it almost always results in a lower TCO. Fewer breakdowns, faster repairs, and greater efficiency lead to significant long-term savings.

Understanding the Trade-offs: The Hidden Costs of Poor Support

Opting for a machine with a lower price tag but no support network is a significant gamble. While it may seem like a savvy short-term decision, it often leads to predictable and expensive problems down the line.

The "Disposable Machine" Trap

The most common issue with unsupported equipment is its effectively disposable nature. The machine may work perfectly for months or even a year.

Then, a minor, inexpensive component fails. Without access to spare parts or technical diagrams, you have no way to fix it, turning your entire investment into a large, useless paperweight.

The Expertise Burden

When you buy a machine without support, you implicitly accept the role of its sole technician. The responsibility for diagnosing complex mechanical or electronic issues falls entirely on you or your staff.

This diverts your focus from your core business—producing and selling honey—to a technical problem you may not be equipped to solve efficiently.

Creeping Inefficiency and Waste

A machine that isn't properly maintained slowly loses its effectiveness. Seals may wear, leading to leaks and wasted product. Nozzles may clog, reducing filling speed. Piston calibration may drift, causing inconsistent fill levels.

Without expert guidance on preventative maintenance, you won't just face catastrophic failures; you will suffer a slow bleed of inefficiency that erodes your profit margin over time.

Making the Right Choice for Your Goal

The level of support you need depends on the scale and complexity of your operation. Evaluating your primary goal will clarify your decision.

- If your primary focus is small-scale or boutique production: Prioritize a machine from a reputable vendor known for reliability and clear documentation that allows you to perform basic maintenance yourself.

- If your primary focus is high-volume commercial output: Non-negotiable support with guaranteed service response times and readily available spare parts is essential to prevent costly line stoppages.

- If your primary focus is product diversity (multiple jar sizes or honey viscosities): Seek a supplier whose support team can provide expert guidance on machine changeovers and recalibration to maintain efficiency across different products.

Ultimately, view maintenance and support not as an expense, but as a critical investment in your business's continuity and success.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimized Downtime | Fast repairs & spare parts access keep your line running. |

| Product Consistency & Hygiene | Easy cleaning & calibration ensure quality and safety. |

| Lower Total Cost of Ownership (TCO) | Fewer breakdowns lead to significant long-term savings. |

| Protection of Investment | Expert support prevents your machine from becoming obsolete. |

Protect your honey production line and profitability. For commercial apiaries and beekeeping equipment distributors, HONESTBEE's wholesale-focused operations provide robust honey filling machines backed by the reliable maintenance, technical support, and readily available spare parts you need to minimize downtime and maximize your return on investment. Contact our experts today to discuss the right filling solution for your operation.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What are the advantages of using automated filling machines for apitherapy? Scaling Medical-Grade Production

- What production challenges are addressed by high-precision honey filling machines? Optimize Your Honey Deep Processing

- What are the core benefits of integrating automated honey-filling machines? Scale Your Production and Brand Value

- Why is professional honey filling machinery necessary for the commercialization of organic honey? Ensure Purity and Scale

- What is the importance of professional honey filling and storage equipment for maintaining honey quality and potency?

- Why is an automated honey-filling machine critical for large-scale commercial honey processing? Boost Efficiency & Purity

- How does the utilization of automated honey filling machines influence biosecurity? Enhance Compliance and Efficiency

- Why is professional honey filling and sealing equipment central to quality control? Secure Your Global Exports