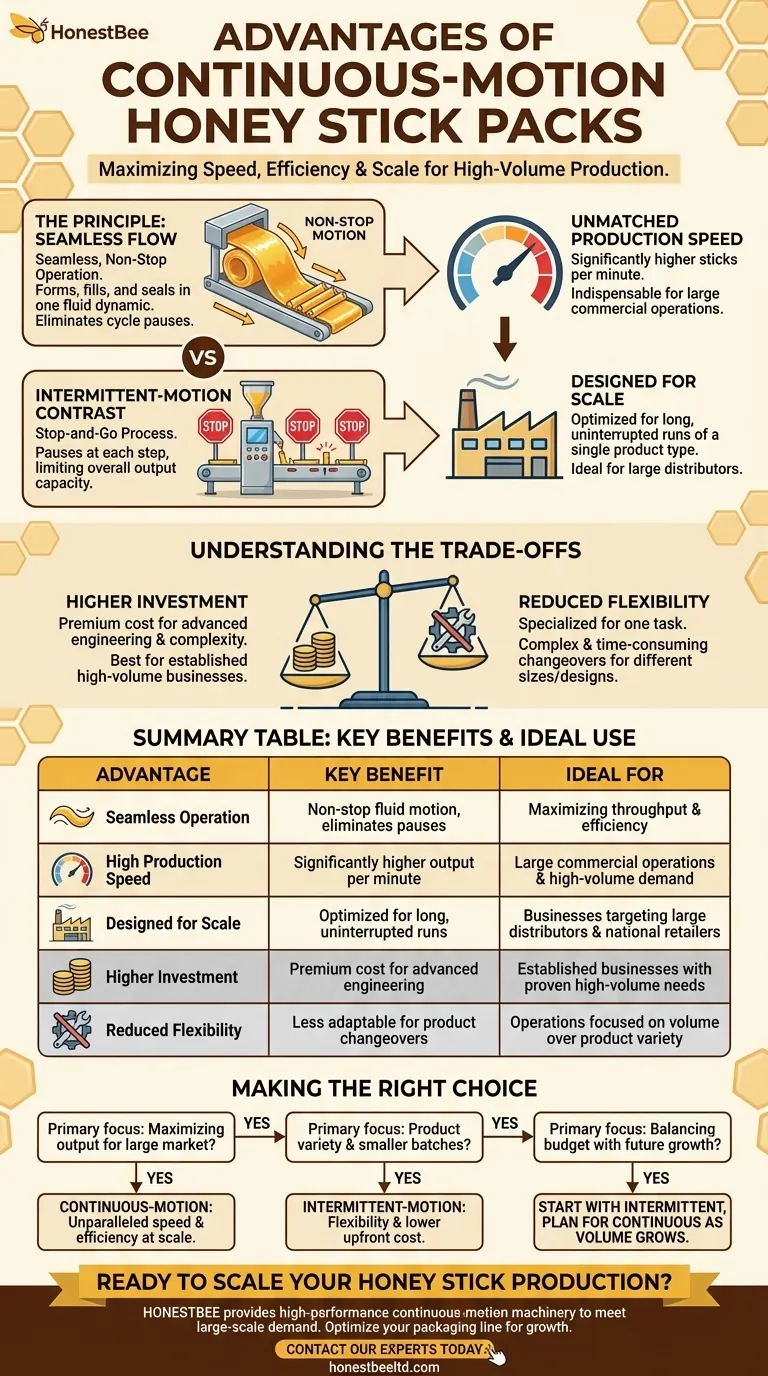

At its core, the primary advantage of a continuous-motion honey stick packing machine is its exceptional speed and efficiency. Unlike intermittent-motion systems that pause between each cycle, a continuous-motion machine operates in a seamless, non-stop flow, making it the superior choice for high-volume production environments where maximizing output is the top priority.

The decision between continuous-motion and intermittent-motion machinery is a strategic choice between scale and flexibility. Continuous-motion is built for maximizing throughput, while intermittent-motion excels in versatility for smaller, more varied production runs.

The Principle of Continuous-Motion Packaging

A continuous-motion machine's value comes from its fundamental design, which eliminates the start-and-stop sequence common in other packaging systems. This creates a fluid, highly efficient production line.

Seamless, Non-Stop Operation

The machine forms, fills, and seals honey sticks while the packaging film moves without interruption. This fluid dynamic is the source of its high-speed capability.

In contrast, an intermittent-motion machine must pause at each step of the process. This "stop-and-go" action inherently limits its overall output capacity.

Unmatched Production Speed

By removing pauses between cycles, continuous-motion machines can package a significantly higher number of honey sticks per minute. This makes them indispensable for large commercial operations.

This high throughput directly translates to meeting the demands of large distributors, national retailers, and extensive supply chains where volume is a key performance indicator.

Designed for Scale

These machines are engineered for the specific purpose of large-scale production. Their design is optimized for long, uninterrupted runs of a single product type.

This focus on scale means they are most effective when you are producing thousands of identical honey sticks in a single shift, rather than switching between different product variations.

Understanding the Trade-offs

While speed is a compelling advantage, it is critical to weigh it against the associated costs and operational constraints. No single solution is perfect for every scenario.

The Higher Initial Investment

The most significant drawback of continuous-motion machinery is the higher initial investment. The complexity and engineering required for seamless, high-speed operation come at a premium.

This makes it a substantial capital expenditure best suited for established businesses with proven high-volume demand, rather than startups or small-batch producers.

Reduced Flexibility and Changeover

Continuous-motion machines are specialists. They are optimized for one task and excel at it, but this specialization comes at the cost of flexibility.

Changing over the machine for a different stick size, design, or volume can be more complex and time-consuming compared to the simpler, more adaptable intermittent-motion systems. Intermittent machines are built for versatility and easy changeovers, making them ideal for businesses with a diverse product portfolio.

The Output Comparison: Continuous vs. Intermittent

The choice ultimately hinges on your production volume. A continuous-motion machine is an investment in scale, while an intermittent machine is an investment in adaptability.

An intermittent machine is more affordable and offers high precision for smaller runs, but it has a clear ceiling on its output capacity. A continuous-motion machine has a much higher ceiling but requires the volume to justify its cost.

Making the Right Choice for Your Operation

To select the correct machine, you must align the technology with your specific business goals.

- If your primary focus is maximizing output for a large market: A continuous-motion machine is the clear choice for its unparalleled speed and per-unit efficiency at scale.

- If your primary focus is product variety and smaller batches: An intermittent-motion machine provides the necessary flexibility and lower upfront cost for a more diverse operation.

- If your primary focus is balancing budget with future growth: Begin with an affordable intermittent machine to establish your product line, with a long-term plan to invest in a continuous-motion system as your volume grows.

Choosing the right equipment is about matching the machine's capabilities to your operational strategy and production demand.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Seamless Operation | Non-stop, fluid motion eliminates cycle pauses | Maximizing throughput and efficiency |

| High Production Speed | Significantly higher output per minute | Large commercial operations & high-volume demand |

| Designed for Scale | Optimized for long, uninterrupted runs of a single product | Businesses targeting large distributors & national retailers |

| Trade-off: Higher Investment | Premium cost for advanced engineering | Established businesses with proven high-volume needs |

| Trade-off: Reduced Flexibility | Less adaptable for product changeovers | Operations focused on volume over product variety |

Ready to Scale Your Honey Stick Production?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the high-performance packaging machinery you need to meet large-scale demand. Our continuous-motion machines are engineered to maximize your output and profitability.

Let's discuss how we can optimize your packaging line for growth. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- 10L Stainless Steel Electric Honey Press Machine

- Professional Thermostatic Conical Honey Melter

People Also Ask

- How does automated filling equipment support the enhancement of market value for honey? Scaling Your Brand Value

- What options are available for filling containers with honey? Scale Your Beekeeping Business Efficiently

- How does industrial honey filling equipment ensure product safety? Secure Your Commercial Honey Production Purity

- What is the working principle of a gravity honey filling machine? A Simple, Cost-Effective Solution

- How do honey filling and filtering machines increase product value? Turn Raw Honey into Premium Export-Grade Goods

- Why are size and material compatibility important when selecting a honey stick machine? Optimize Your Production Line

- In what ways do automatic honey-filling machines enhance honey post-processing? Scale Efficiency and Profitability

- How do honey filtration and filling machinery contribute to industrialization? Scale Your Commercial Honey Production