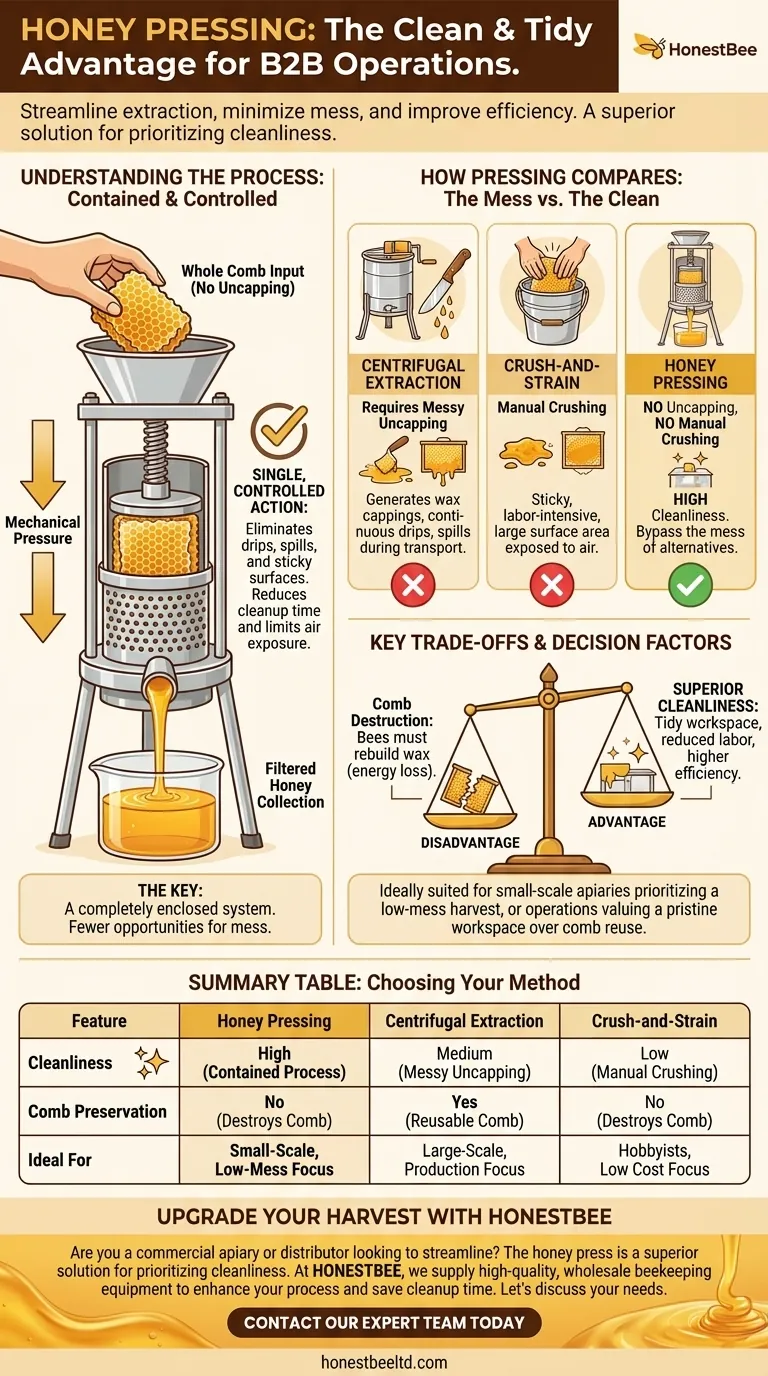

The primary advantage of pressing honey is that it offers a significantly cleaner and more contained extraction process compared to other non-mechanical methods. By eliminating the need to uncap honeycomb frames and avoiding manual crushing, it drastically reduces drips, spills, and the overall mess associated with harvesting.

Honey pressing streamlines extraction into a single, controlled action. This minimizes sticky surfaces, reduces cleanup time, and limits the honey's exposure to air, preserving its quality.

Understanding the Honey Pressing Process

What is Honey Pressing?

Honey pressing is a method of extraction where entire chunks of honeycomb are placed into a press. Mechanical force is then applied, typically via a screw mechanism, which squeezes the comb.

This pressure breaks the wax cells and forces the liquid honey out, which is then filtered and collected below. The beeswax is left behind as a compressed "puck."

The Key to a Tidy Harvest

The entire process happens within the confines of the press. The comb goes in, and honey flows out through a designated spout into a waiting container.

This contained system is the core reason for its cleanliness. There are far fewer opportunities for honey to drip onto floors, equipment, or work surfaces.

How Pressing Compares to Other Methods

The Mess of Centrifugal Extraction

The most common commercial method, centrifugal extraction, requires an initial step called uncapping. Beekeepers must slice or scrape the wax caps off every single cell before placing the frame in an extractor.

This uncapping process is inherently messy. It generates wax cappings soaked in honey, which drip continuously. Transporting the uncapped frames from the uncapping station to the extractor creates another source of spills.

The Drawback of Crush-and-Strain

The simplest low-tech method, crush-and-strain, involves mashing up the honeycomb by hand or with a tool in a bucket. This mixture is then poured through a sieve to separate the honey from the wax.

While it requires minimal equipment, crushing comb by hand is a sticky, labor-intensive process that exposes a large surface area of honey to the air for an extended period.

The Cleanliness of Pressing

A honey press neatly bypasses the mess of both alternatives. There is no uncapping step and no manual crushing. The comb is handled once when it's placed in the press, and the machine does the rest of the work cleanly.

Key Trade-offs to Consider

Comb Destruction is a Major Factor

The most significant disadvantage of pressing is that it completely destroys the comb. Bees expend a tremendous amount of energy and resources to build beeswax comb.

Centrifugal extraction, by contrast, preserves the drawn-out comb, which can be returned to the hive. This gives the colony a massive head start on storing honey for the next season.

Equipment and Scale

While cleaner than crushing by hand, a honey press is still a piece of equipment that must be purchased and thoroughly cleaned after use.

For very small-scale or hobbyist beekeepers, the simplicity and low cost of crush-and-strain might outweigh the mess. For large-scale operations, the efficiency and comb-saving nature of centrifugal extractors are superior.

Making the Right Choice for Your Goal

- If your primary focus is a clean, low-mess harvest for a small-scale apiary: Honey pressing is an excellent choice that balances tidiness and simplicity.

- If your primary focus is maximizing honey production and colony efficiency: Centrifugal extraction is the standard because it saves the valuable drawn comb for reuse.

- If your primary focus is the lowest possible equipment cost: The crush-and-strain method is the most accessible, but you must be prepared for a significant cleanup effort.

Ultimately, choosing to press honey is a strategic decision that prioritizes a clean and tidy workspace over the preservation of beeswax comb.

Summary Table:

| Feature | Honey Pressing | Centrifugal Extraction | Crush-and-Strain |

|---|---|---|---|

| Cleanliness | High (Contained Process) | Medium (Messy Uncapping) | Low (Manual Crushing) |

| Comb Preservation | No (Destroys Comb) | Yes (Reusable Comb) | No (Destroys Comb) |

| Ideal For | Small-Scale, Low-Mess Focus | Large-Scale, Production Focus | Hobbyists, Low Cost Focus |

Achieve a Cleaner, More Efficient Honey Harvest with HONESTBEE

Are you a commercial apiary or beekeeping equipment distributor looking to streamline your operation and reduce the sticky mess of honey extraction? The honey press is a superior solution for prioritizing cleanliness and a tidy workspace.

At HONESTBEE, we specialize in supplying high-quality, wholesale beekeeping supplies and equipment. We can help you select the right tools, like honey presses, to enhance your harvesting process, save valuable cleanup time, and maintain the highest quality of your honey.

Ready to upgrade your harvest? Let's discuss how our equipment can benefit your specific needs. Contact our expert team today for wholesale pricing and recommendations!

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- How does the honey separation and pressing process work in the Wax Screw Presses set? Maximize Honey Yield from Cappings

- What is the primary function of a honey screw press? Maximize Yield with Advanced Cold Press Separation Technology

- What is the process for extracting honey using a honey press? Maximize Your Yield with Gentle Cold-Pressing

- What happens to the pressed wax after using a honey press? Maximize Your Harvest and Beeswax Yield

- How do larger beekeeping operations benefit from using honey presses? Maximize Efficiency and Wax Yield

- How long does the process of separating beeswax from honey typically take? Optimize Your Harvest Timeline

- How does the honeycomb pressing process affect honey? Boost Antioxidants and Bioactive Content Naturally

- What is the procedure for extracting honey using a honey press? A Guide to Maximum Yield