In the confectionery industry, a honey stick machine provides significant operational and market advantages. Its core benefits stem from combining high-speed, automated production with the ability to create convenient, single-serve products. This technology reduces material costs, enhances product versatility, and directly meets modern consumer demands for portable and hygienic packaging.

The true value of a honey stick machine is its function as a strategic asset. It moves beyond packaging a single product to enabling a business to cost-effectively produce a wide range of popular, single-serve confections that align with modern consumer preferences.

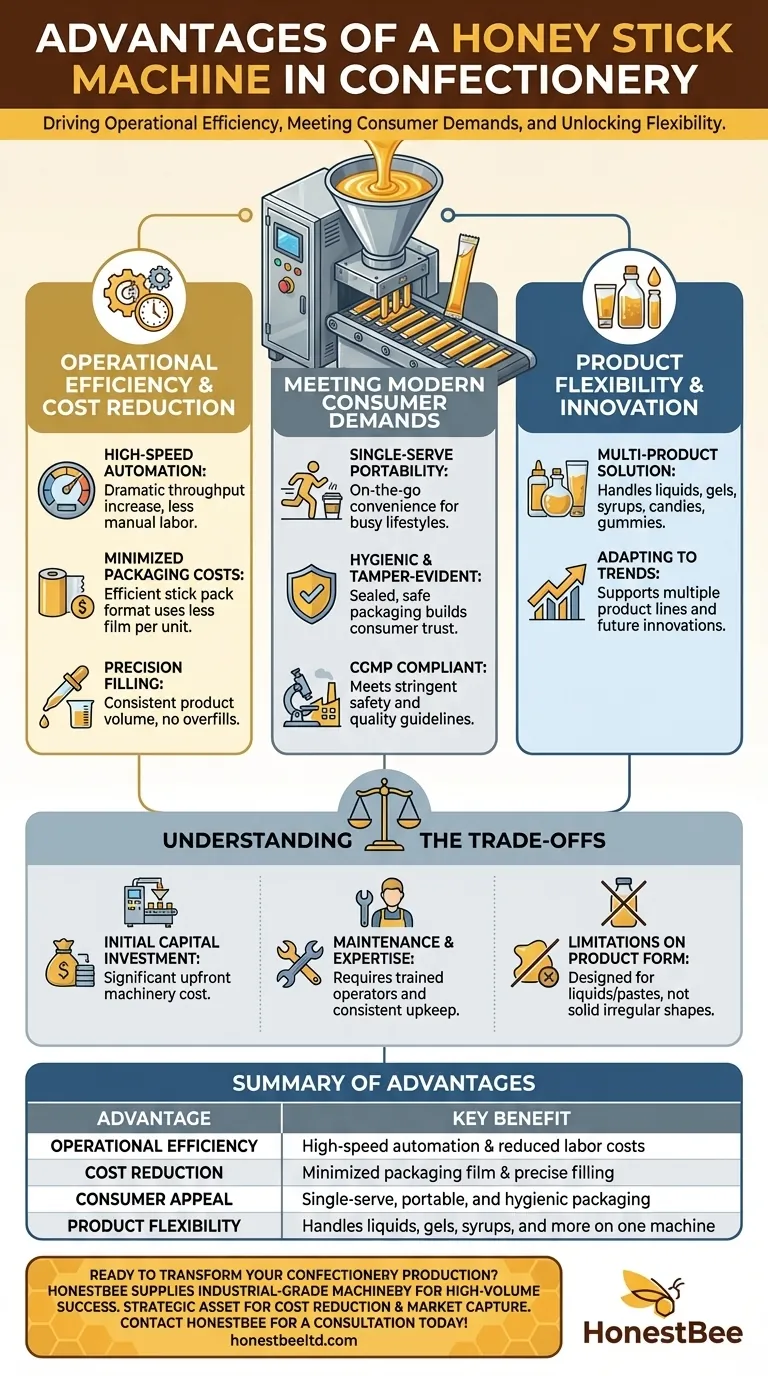

Driving Operational Efficiency and Cost Reduction

For any confectionery business, optimizing the production line is a primary goal. This machine directly addresses key performance indicators by automating processes and minimizing waste.

High-Speed Automated Production

A honey stick machine automates the entire form, fill, and seal process. This dramatic increase in speed and throughput allows for higher output with less manual labor, directly boosting overall production efficiency.

Minimized Packaging Costs

The stick pack format is inherently efficient, using minimal packaging film compared to other single-serve containers like tubs or sachets. This reduction in material consumption per unit leads to significant, ongoing cost savings.

Precision Filling for Product Consistency

Equipped with accurate piston or volumetric pumps, these machines ensure precise filling for every stick. This consistency prevents costly product over-fills and guarantees that every customer receives the same product experience.

Meeting Modern Consumer Demands

Success in the confectionery market is not just about the product, but also its presentation and convenience. The stick pack format is a proven winner with end-users.

The Appeal of Single-Serve Portability

Consumers overwhelmingly favor products that fit their on-the-go lifestyles. Stick packs are lightweight, durable, and easy to use, making them the ideal format for everything from liquid candies to hot chocolate mixes.

Hygienic and Tamper-Evident Design

The sealed nature of a stick pack provides a hygienic, tamper-evident container that builds consumer trust. Many machines are built to cGMP (current Good Manufacturing Practice) guidelines, ensuring the packaging process meets stringent safety and quality standards.

Unlocking Product Flexibility and Innovation

While named for honey, this machine's utility extends far beyond a single product. Its flexibility is one of its greatest assets, allowing a business to adapt and innovate.

A Multi-Product Solution

These machines can handle a wide variety of liquid, gel, and even some powder products. In the confectionery space, this includes liquid chewing gums, chocolate sauces, flavored syrups, candies, and gummies, all packaged on the same equipment.

Adapting to Changing Market Trends

The ability to produce various stick pack designs and handle different products allows a company to quickly respond to shifting market demands. A single machine can support multiple product lines, future-proofing the initial investment.

Understanding the Trade-offs

No technology is a perfect solution. An objective evaluation requires acknowledging potential limitations.

Initial Capital Investment

Acquiring specialized packaging machinery represents a significant upfront capital expenditure. The return on investment must be carefully calculated based on projected production volume and cost savings.

Maintenance and Technical Expertise

These are sophisticated machines that require trained operators and a consistent maintenance schedule to ensure reliable, long-term performance.

Limitations on Product Form

Stick pack machines are designed for liquids, gels, pastes, and free-flowing powders. They are not suitable for solid, irregularly shaped confectionery, which requires different packaging solutions.

Making the Right Choice for Your Production Line

Integrating a honey stick machine is a strategic decision that should align with your specific business goals.

- If your primary focus is cost reduction and efficiency: The machine's ability to automate packaging and minimize film usage will directly lower your cost-per-unit.

- If your primary focus is market expansion: This technology allows you to produce the highly popular, portable, single-serve stick packs that modern consumers demand.

- If your primary focus is product line versatility: The machine's flexibility to handle various liquid and semi-liquid products enables future innovation without requiring new equipment.

Ultimately, adopting this technology empowers your business to produce desirable products more efficiently and economically.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Operational Efficiency | High-speed automation & reduced labor costs |

| Cost Reduction | Minimized packaging film & precise filling |

| Consumer Appeal | Single-serve, portable, and hygienic packaging |

| Product Flexibility | Handles liquids, gels, syrups, and more on one machine |

Ready to transform your confectionery production?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the industrial-grade machinery needed for high-volume success. A honey stick machine is more than packaging—it's a strategic asset for reducing costs and capturing the single-serve market.

Let our experts help you select the right equipment to boost your efficiency and product line. Contact HONESTBEE today for a personalized consultation!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

People Also Ask

- In large-scale beekeeping, how do automatic honey filling machines impact the commercialization process of products?

- What types of containers can be filled using a honey filler? Optimize Your Packaging for Any Container

- How does automated honey filling equipment contribute to international standards for honeydew honey exports?

- How does the use of professional honey-filling machinery improve the commercial value of stingless bee honey?

- What role do automatic honey-filling machines play? Enhancing Honey Purity and Commercial Sustainability

- How does high-precision honey-filling equipment influence the market competitiveness of beekeeping products?

- What are the different types of liquid filling machines? Find the Perfect Fit for Your Product's Viscosity & Speed

- What are the advantages of using a food-grade syringe for filling honey straws? Precision and Hygiene for Apiaries