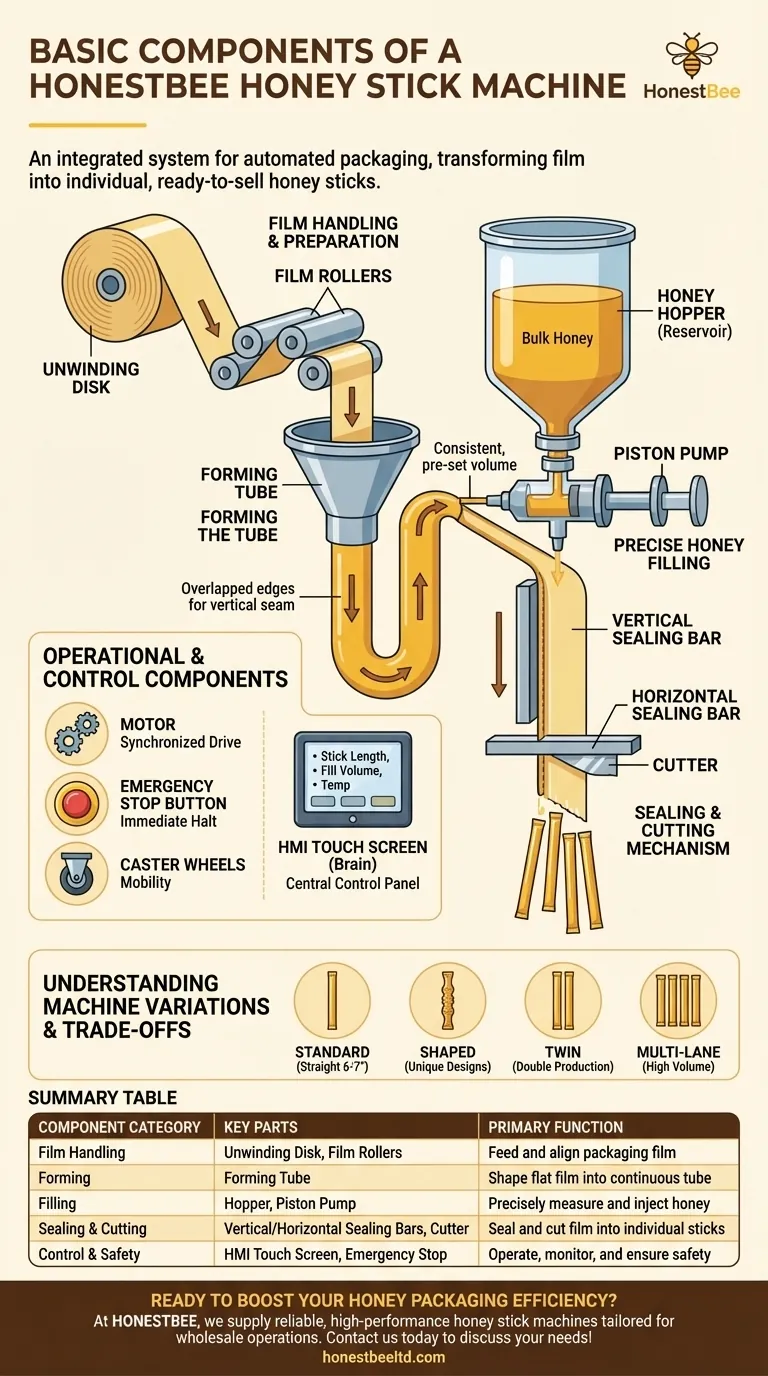

At its core, a honey stick machine is an integrated system of mechanical and electronic components designed for automated packaging. The primary parts include a film handling system (unwinding disk, film roller), a forming tube, a honey delivery system (hopper, piston pump), and a sealing and cutting mechanism (vertical/horizontal sealing bars, cutter), all controlled by an HMI touch screen.

A honey stick machine automates a precise sequence: it takes a roll of flat packaging film, forms it into a continuous tube, fills it with a measured amount of honey, and then seals and cuts it to create individual, ready-to-sell sticks.

The Core Process: From Film to Finished Stick

Understanding the function of each component reveals how the machine transforms raw materials into a final product in a synchronized, continuous motion.

Film Handling and Preparation

The process begins with the unwinding disk, which holds the large roll of flat packaging film.

As the machine operates, the film is pulled off the roll and guided by a series of film rollers. These rollers maintain proper tension and alignment as the film travels toward the forming station.

Forming the Tube

The flat film is then fed into a forming tube (also known as a former). This critical component shapes the flat film into a vertical, continuous tube by overlapping its edges.

Precise Honey Filling

A honey hopper serves as the reservoir, holding the bulk honey that will be packaged.

From the hopper, a piston pump draws a precise, pre-set volume of honey. This ensures every stick contains a consistent amount of product. The honey is then injected down through the forming tube into the sealed bottom of the film tube at the filling station.

Sealing and Cutting

Before the honey is injected, a vertical sealing bar presses the overlapped edges of the film together, creating the long, vertical seam of the stick.

Simultaneously, a horizontal sealing bar moves in to create the top seal of the filled stick and the bottom seal of the next one. This heated bar clamps the film tube, sealing it shut.

Immediately after the horizontal seal is made, a cutter (or blade) slices through the middle of the seal, separating the finished honey stick from the film tube above it. The stick then discharges from the machine.

Operational and Control Components

These components allow an operator to control the machine, ensure safety, and manage its physical placement.

The Machine's Brain (HMI)

The HMI (Human-Machine Interface) touch screen is the central control panel. It allows the operator to set parameters like stick length, fill volume, and sealing temperature, as well as to start, stop, and troubleshoot the machine.

The Powerhouse and Safety

A central motor drives the mechanical actions of the rollers, pumps, and sealing bars, ensuring all movements are perfectly synchronized.

An emergency stop button is a critical safety feature that, when pressed, immediately halts all machine operations. Caster wheels are often included on the machine's frame to provide mobility for cleaning and repositioning within a facility.

Understanding Machine Variations and Trade-offs

Not all honey stick machines are the same. Their design directly relates to production scale and market strategy, presenting clear trade-offs in cost and capability.

Standard vs. Shaped Machines

A standard machine produces the familiar 6-7 inch straight honey stick. These machines are the most common and cost-effective solution for basic production.

A shaped honey stick machine uses custom sealing and cutting dies to create unique shapes or embossed patterns on the seals. While this requires a higher initial investment, it can increase marketability, especially for brands targeting children or premium niches.

Single-Lane vs. Multi-Lane Automation

A twin honey stick machine is a simple form of multi-lane production, featuring two parallel sets of forming, filling, and sealing components to produce two sticks at once.

A fully automatic honey stick machine often features multiple lanes (more than two) for high-volume, large-scale industrial production. These systems handle nearly every step from loading to discharge with minimal operator intervention but require significant space and capital.

Making the Right Choice for Your Goal

Selecting the right machine requires aligning its features with your specific business objectives.

- If your primary focus is brand differentiation and niche marketing: A shaped machine offers the best path to creating a unique product that stands out on the shelf.

- If your primary focus is increasing output beyond a basic level: A twin honey stick machine provides a significant boost in production efficiency without the complexity of a large-scale industrial system.

- If your primary focus is maximizing volume for large-scale distribution: A fully automatic, multi-lane machine is the necessary tool for achieving the highest possible output and automation.

Ultimately, choosing the right equipment comes down to a clear understanding of how each component contributes to your production speed, product appearance, and overall operational goals.

Summary Table:

| Component Category | Key Parts | Primary Function |

|---|---|---|

| Film Handling | Unwinding Disk, Film Rollers | Feed and align packaging film |

| Forming | Forming Tube | Shape flat film into a continuous tube |

| Filling | Hopper, Piston Pump | Precisely measure and inject honey |

| Sealing & Cutting | Vertical/Horizontal Sealing Bars, Cutter | Seal and cut film into individual sticks |

| Control & Safety | HMI Touch Screen, Emergency Stop | Operate, monitor, and ensure safety |

Ready to boost your honey packaging efficiency? At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with reliable, high-performance honey stick machines tailored for wholesale operations. Whether you need a standard, shaped, or multi-lane system, our solutions are designed to maximize your output and product quality. Contact us today to discuss your needs and get a customized quote!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

People Also Ask

- What functions do specialized honey-filling machines perform? Maximize Post-Harvest Efficiency & Purity

- How do high-standard honey filling and sealing machines contribute to honey quality? Secure Your Export Standards

- Why is the establishment of a seasonal flowering calendar critical? Optimize Your Honey Filling Production Today

- What are the causes and solutions for a honey stick machine overheating? Expert Troubleshooting Guide

- How does a piston filling machine function? Master High-Accuracy Viscous Product Filling

- How do large honey storage tanks and gravity fall filling systems improve honey packaging efficiency and safety?

- What are the requirements for container processing before packaging stingless bee honey to ensure storage stability?

- What are the features of a twin honey stick machine? Double Your Production & Versatility