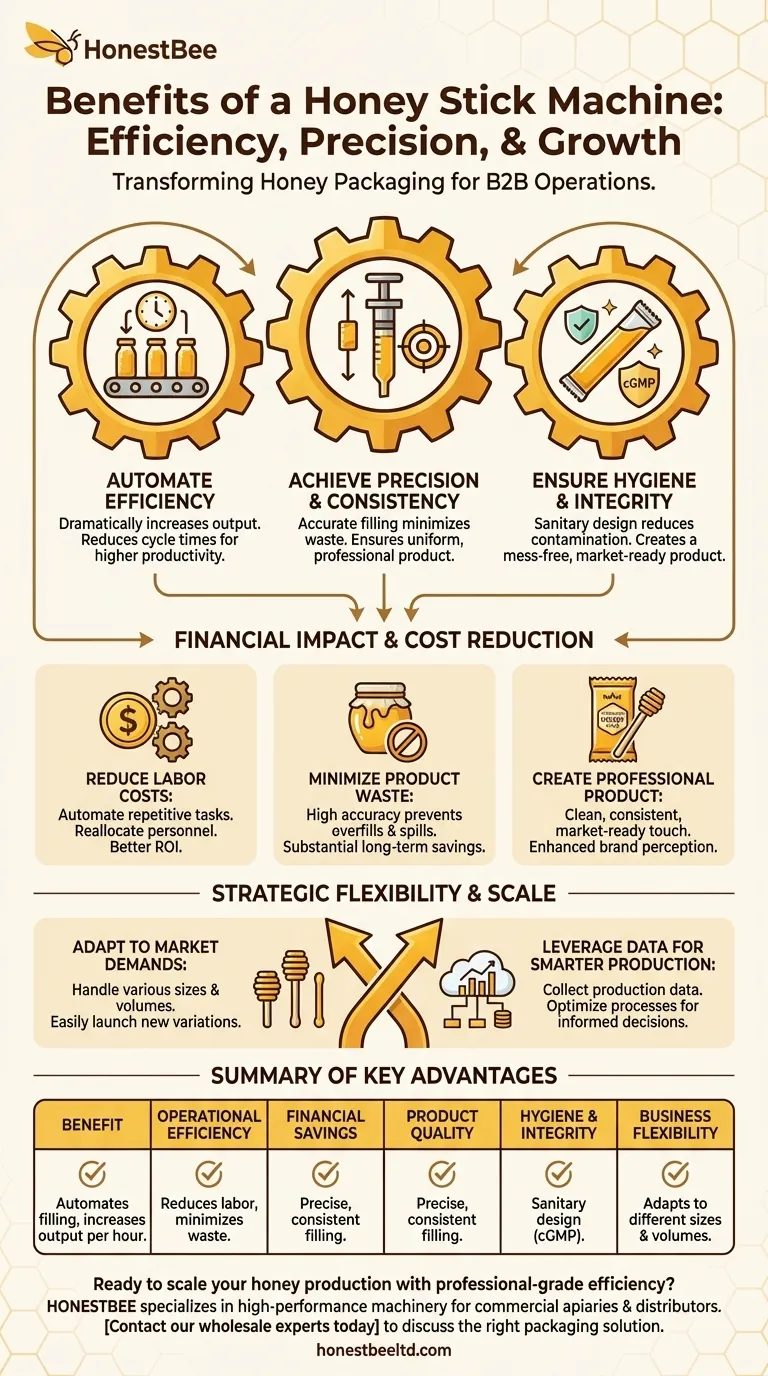

At its core, a honey stick machine provides a powerful combination of high production efficiency, filling accuracy, and operational flexibility. It automates the process of packaging single servings of honey into tubular stick packs, dramatically increasing output while ensuring a consistent, professional-quality product that minimizes waste and reduces labor costs.

The decision to invest in a honey stick machine is about more than just speed. It represents a fundamental shift from manual, labor-intensive packaging to a streamlined, scalable, and data-informed production system that reduces waste and elevates your brand's quality.

Beyond Speed: The Core Operational Advantages

True efficiency is not just about moving faster. It's about improving the entire production process, from consistency to hygiene, which is where this equipment truly excels.

Automating for Unmatched Efficiency

A honey stick machine automates the entire packaging workflow, from filling to sealing.

This automation significantly reduces production cycle times, allowing you to process far more sticks per hour than any manual method could achieve. The direct result is a dramatic increase in your overall productivity and output capacity.

Achieving Precision and Consistency

These machines are engineered with piston and volumetric pumps for highly accurate and precise filling.

This engineering minimizes spillage and product waste, ensuring each stick contains the correct, specified volume of honey. This consistency reinforces your product's quality and gives every honey stick a uniform, professional appearance.

Ensuring Product Integrity and Hygiene

Many machines are built with a hygienic design, often adhering to cGMP (current Good Manufacturing Practice) guidelines.

This focus on sanitary construction reduces the risk of contamination during packaging, safeguarding the integrity of your product. The final output is a clean, perfectly sealed, and mess-free honey stick ready for market.

Analyzing the Financial Impact

The benefits of automation extend directly to your bottom line through cost reduction and waste elimination.

Reducing Direct Labor Costs

By automating a repetitive and time-consuming task, the machine significantly lowers your reliance on manual labor for packaging. This allows you to reallocate personnel to more critical tasks and provides a clear return on investment over time.

Minimizing Product Waste

The high accuracy of automated filling directly translates to less wasted honey from overfills or spills. Over thousands of production cycles, this reduction in lost product can lead to substantial cost savings.

Creating a Professional, Market-Ready Product

Automated packaging provides a clean, consistent, and professional touch that is difficult to replicate manually. This enhanced presentation can improve brand perception and marketability.

Understanding the Trade-offs

To make an informed decision, it is critical to weigh the advantages against the practical considerations of owning and operating specialized equipment.

Initial Capital Investment

Acquiring this machinery requires a significant upfront financial commitment. The cost must be carefully weighed against the projected savings in labor and waste, as well as the potential for increased revenue from higher output.

Operational Scale

A honey stick machine is most effective for businesses looking to scale production significantly. For very small-batch or hobbyist producers, the production volume may not yet justify the investment compared to manual methods.

Maintenance and Training

Like any piece of industrial equipment, these machines require regular maintenance and cleaning to ensure longevity and hygiene. Operators will also need proper training to handle the machine safely and efficiently.

Gaining Strategic Flexibility

Beyond immediate efficiency gains, this equipment provides the flexibility to adapt and grow your business.

Adapting to Market Demands

These machines are often designed to be flexible, capable of handling various stick sizes, volumes, and packaging designs. This adaptability allows you to easily meet changing consumer preferences or launch new product variations.

Leveraging Data for Smarter Production

Automated systems provide the opportunity for better data collection on production runs, output, and efficiency. This data enables more informed decision-making, helping you optimize processes and identify areas for improvement.

Making the Right Choice for Your Operation

The decision to invest depends entirely on your specific business objectives.

- If your primary focus is scaling production: A honey stick machine is a direct path to higher output, enabling you to meet larger orders and expand your market reach.

- If your primary focus is brand quality and consistency: The machine delivers a uniform, professionally sealed product every time, which builds customer trust and elevates your brand's perception.

- If your primary focus is operational efficiency: Automation is the key to reducing per-unit labor costs, minimizing product waste, and creating a more predictable workflow.

Investing in this technology is a decisive step toward transforming your honey production into a more professional, profitable, and scalable enterprise.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Operational Efficiency | Automates filling & sealing, dramatically increasing output per hour. |

| Financial Savings | Reduces labor costs and minimizes product waste from spills. |

| Product Quality | Ensures precise, consistent filling for a professional, market-ready product. |

| Hygiene & Integrity | Sanitary design (cGMP) reduces contamination risk with clean, sealed sticks. |

| Business Flexibility | Adapts to different stick sizes and volumes for new product variations. |

Ready to scale your honey production with professional-grade efficiency?

As HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the high-performance machinery needed to grow. Our honey stick machines are designed to deliver the precise filling, operational savings, and brand-enhancing consistency detailed in this article.

Let us help you boost your output and profitability. Contact our wholesale experts today to discuss the right packaging solution for your operation.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- Why are industrial Honey-filling machines essential for organic forest honey? Maximize Purity and Market Value

- How does a VFFS liquid packaging machine handle honey packaging? Master Viscous Liquid Filling

- What characteristics contribute to the versatility of semi-automatic filling machines? Optimize Your Production Flow

- How do professional-grade honey-filling machines enhance commercial value? Boost Safety & Scaling Potential

- How do industrial honey-filling machines address infrastructure deficiencies? Standardize Your Logistics & Branding

- How do modern automatic filling and sealing machines improve operational efficiency? Scale Your Honey Distribution Now

- How do automated honey-filling machines assist in scaling beekeeping operations for international export? Scale Global

- Why has the small bag honey packaging machine been favored by manufacturers? Unlock Efficiency & Quality