At its core, an automatic honey filling machine elevates your production by making it faster, more precise, and highly consistent. This automation directly translates into reduced waste, lower labor costs, and a significant increase in overall output, allowing your operation to scale efficiently.

The decision to adopt an automatic honey filling machine is not merely about replacing a manual task. It's a strategic investment in transforming your packaging process from a potential bottleneck into a streamlined, professional, and reliable asset for your business.

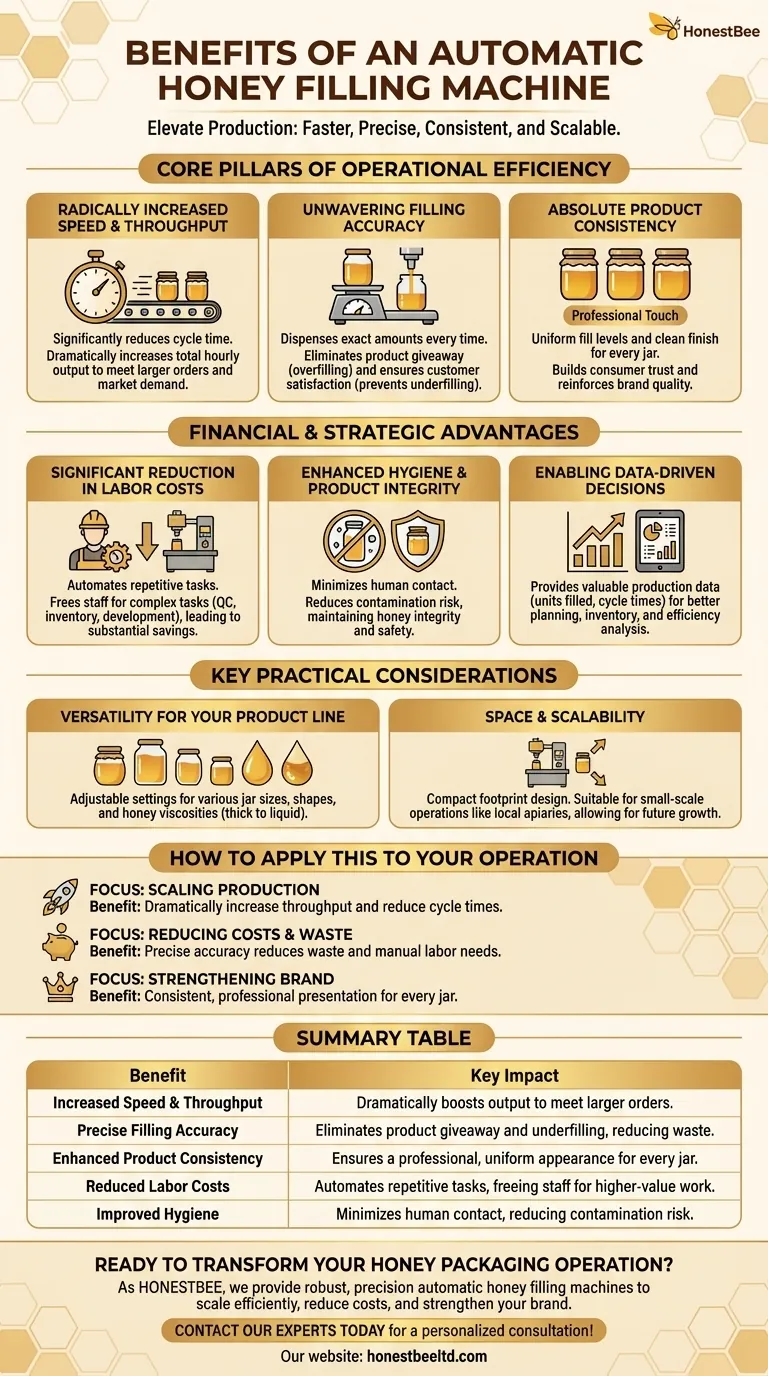

The Core Pillars of Operational Efficiency

Automating the filling process introduces fundamental improvements that ripple through your entire workflow, impacting everything from raw material usage to final product presentation.

Radically Increased Speed and Throughput

An automatic machine operates at a pace that manual labor cannot sustain. By significantly reducing the cycle time for filling each jar, you can dramatically increase your total output per hour.

This allows you to meet larger orders, respond faster to market demand, and scale your production capabilities without a proportional increase in labor.

Unwavering Filling Accuracy

Precision is a key benefit of automation. The machine dispenses the exact same amount of honey into every single jar, eliminating the inconsistencies of manual filling.

This accuracy is critical for profitability. It prevents product giveaway from overfilling and ensures customer satisfaction by avoiding underfilling, directly reducing waste and protecting your brand's reputation.

Absolute Product Consistency

Every jar that comes off the line will look uniform, with consistent fill levels and a clean finish. This consistency gives your product a professional touch that builds consumer trust and reinforces brand quality.

It removes the variability that can make a small-batch product look unprofessional, ensuring your packaging is as high-quality as the honey inside.

The Financial and Strategic Advantages

Beyond the immediate production floor benefits, an automatic filler provides tangible advantages that impact your bottom line and strategic planning.

Significant Reduction in Labor Costs

A filling machine automates one of the most repetitive and time-consuming tasks in the packaging process.

This frees your valuable team members from manual filling, allowing them to focus on more complex tasks like quality control, inventory management, or new product development. Over time, this leads to substantial savings in labor costs.

Enhanced Hygiene and Product Integrity

Automated systems minimize human contact with the product during packaging. This is a crucial advantage in food production, as it reduces the risk of contamination and helps maintain the integrity and hygiene of your honey.

Enabling Data-Driven Decisions

Modern filling machines can offer valuable data on production runs, such as the number of units filled and cycle times. This information allows for better production planning, inventory management, and analysis of your operational efficiency.

Key Practical Considerations

When evaluating a machine, its adaptability to your specific needs is just as important as its core benefits.

Versatility for Your Product Line

Look for machines with adjustable settings. The ability to easily adapt to different jar sizes and shapes is essential if you offer a variety of products.

Furthermore, adjustability for different honey viscosities ensures you maintain filling accuracy whether you are packaging thick, creamy honey or a thinner, liquid variety.

Space and Scalability

Many modern honey filling machines are designed with a compact footprint. This makes them a viable option even for small-scale operations like local apiaries or small food manufacturers where production space is limited.

How to Apply This to Your Operation

The right motivation for investing in an automatic filler depends on your primary business goal.

- If your primary focus is scaling production: The machine's ability to reduce cycle times and dramatically increase throughput is your key benefit.

- If your primary focus is reducing costs and waste: The precise filling accuracy and reduction in manual labor needs will deliver the most significant financial return.

- If your primary focus is strengthening your brand: The machine's consistency ensures a professional, high-quality presentation for every jar you sell.

Ultimately, investing in an automatic filling machine is an investment in the professionalism, efficiency, and future growth of your operation.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Increased Speed & Throughput | Dramatically boosts output to meet larger orders. |

| Precise Filling Accuracy | Eliminates product giveaway and underfilling, reducing waste. |

| Enhanced Product Consistency | Ensures a professional, uniform appearance for every jar. |

| Reduced Labor Costs | Automates repetitive tasks, freeing staff for higher-value work. |

| Improved Hygiene | Minimizes human contact, reducing contamination risk. |

Ready to transform your honey packaging operation?

As HONESTBEE, a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we provide the robust, precision automatic honey filling machines your business needs to scale efficiently, reduce costs, and strengthen your brand.

Let us help you select the ideal equipment to boost your productivity and profitability. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How does production volume influence the choice of a honey packaging machine? Scale Your Operation Efficiently

- What is the practical application of the pycnometer method for honey density? Optimize Your Packaging & Filling

- How do automatic or semi-automatic honey-filling machines contribute to commercialization? Scale Your Honey Production

- What role do automatic honey-filling machines play in the commercial packaging of honey? Scaling for Global Markets

- Why are automated filling machines essential for stingless bee honey? Secure Quality and Scale Your Commercialization

- What is the indirect impact of bee predators on honey filling equipment? Optimize ROI through supply chain stability.

- In what ways do industrial-grade honey filling and packaging machines enhance the commercial competitiveness? - HONESTBEE

- What is the process of a sachet filling machine? Optimize Your Packaging Line for Accuracy & Speed