The primary benefits of a wire mesh beehive floor are superior ventilation and a highly effective method for controlling Varroa mites. This design, often called a screened bottom board, fundamentally changes the hive's internal environment by preventing moisture buildup, simplifying cleaning, and disrupting the lifecycle of one of beekeeping's most destructive pests.

A screened bottom board is not just a structural component; it is a critical tool for Integrated Pest Management (IPM) and climate control within the hive. Adopting one directly impacts colony health and significantly reduces the beekeeper's workload.

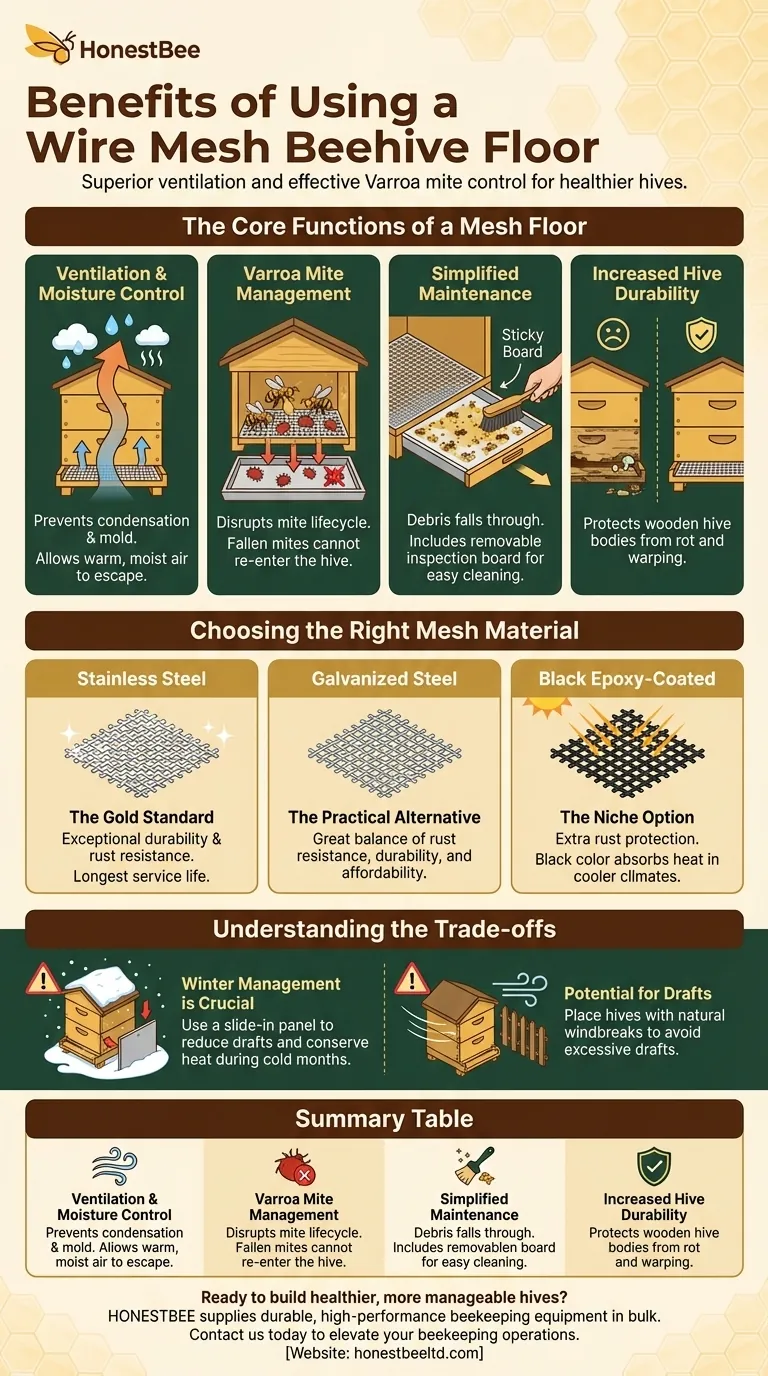

The Core Functions of a Mesh Floor

A solid wood floor is traditional, but a wire mesh floor actively solves several of the most persistent challenges in beekeeping. It transforms the bottom of the hive from a passive floor into an active management system.

Enhancing Ventilation and Moisture Control

Proper airflow is critical for a colony's health. Bees generate significant heat and water vapor through respiration and nectar curing.

A mesh floor allows this warm, moist air to escape, along with waste gases like carbon dioxide. This constant circulation prevents condensation from forming and dripping down on the bees, which can be fatal during cold weather. It also denies mold and fungus the damp environment they need to grow.

A Critical Tool for Varroa Mite Management

The Varroa destructor mite is a primary threat to honeybee colonies worldwide. Screened bottom boards are a simple, non-chemical defense against them.

During their natural grooming or movement, mites can fall off a bee. With a solid floor, the mite can simply wait for another bee to walk by and climb back on. With a mesh floor, the mite falls completely out of the hive, breaking its lifecycle and reducing the overall mite population within the colony.

Simplifying Hive Maintenance and Cleaning

Debris naturally accumulates at the bottom of a hive, including wax cappings, pollen, and dead bees. A wire mesh floor allows much of this debris to fall directly to the ground.

Most screened bottom boards also include a removable insert, often called a "sticky board" or inspection board. Beekeepers can slide this out to easily monitor what is falling from the hive (like mites) and clean it off without disturbing the colony above.

Increasing Overall Hive Durability

Moisture is the enemy of wooden beekeeping equipment. By preventing moisture buildup, a mesh floor protects the wooden hive bodies from rot and warping.

The metal mesh itself is also highly durable and resistant to pests like wax moths that might otherwise burrow into a wooden bottom board, extending the functional life of your equipment.

Choosing the Right Mesh Material

The material you choose impacts longevity, maintenance, and even the hive's microclimate.

Stainless Steel: The Gold Standard

Stainless steel is the premium choice for its exceptional durability and resistance to corrosion. It is the easiest to clean and will not rust, ensuring a long service life. While the initial cost is higher, it is often the most cost-effective option in the long term.

Galvanized Steel: The Practical Alternative

Galvanized steel is coated with a layer of zinc to provide excellent rust resistance. It is durable, easy to maintain, and offers a great balance of performance and affordability, making it a very popular and practical choice for most beekeepers.

Black Epoxy-Coated: The Niche Option

This type of mesh provides an extra layer of protection against rust. A unique benefit is that its black color absorbs heat from the sun, which can help warm the hive. This can be a slight advantage in cooler climates during the spring buildup.

Understanding the Trade-offs

While highly beneficial, a screened bottom board is not a "set it and forget it" solution. Its primary advantage—airflow—can become a liability in certain situations if not managed properly.

Winter Management is Crucial

In regions with cold winters, the constant airflow from an open mesh floor can make it difficult for the colony to maintain its crucial winter cluster temperature.

Nearly all screened bottom boards are designed to accept a slide-in panel (often made of wood or corrugated plastic). Inserting this board during the coldest months closes off the bottom, reducing drafts and helping the bees conserve heat.

Potential for Drafts

Even outside of winter, a poorly sited hive exposed to strong, prevailing winds could experience excessive drafts through the mesh floor. Placing hives in a location with a natural windbreak is always a best practice.

Making the Right Choice for Your Apiary

Your specific goals and climate should guide your decision to use and manage a wire mesh floor.

- If your primary focus is Varroa mite control and low maintenance: A screened bottom board is essential; choose stainless steel for maximum longevity.

- If you are beekeeping in a very cold climate: Use a mesh floor but be sure to insert a winter board to manage heat loss during the coldest months.

- If your primary focus is budget-friendliness without sacrificing core benefits: Galvanized steel mesh offers the best balance of durability, rust resistance, and cost.

Ultimately, incorporating a wire mesh floor is a strategic upgrade that empowers you to create a healthier, more resilient, and more easily managed environment for your bees.

Summary Table:

| Benefit | Key Function |

|---|---|

| Ventilation & Moisture Control | Prevents condensation, mold, and fungus by allowing warm, moist air to escape. |

| Varroa Mite Management | Disrupts mite lifecycle; fallen mites cannot re-enter the hive. |

| Simplified Maintenance | Debris falls through; includes a removable inspection board for easy cleaning. |

| Increased Hive Durability | Protects wooden hive bodies from rot and warping by reducing moisture buildup. |

Ready to build healthier, more manageable hives? For commercial apiaries and equipment distributors, HONESTBEE supplies durable, high-performance beekeeping equipment in bulk, including premium stainless steel and galvanized steel screened bottom boards. Our wholesale-focused operations ensure you get the reliable supplies you need to support thriving colonies and effective Integrated Pest Management (IPM) strategies. Contact HONESTBEE today to discuss your wholesale needs and elevate your beekeeping operations.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Langstroth Solid Bottom Board for Beekeeping

- Professional Bamboo Queen Isolation Cage

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What role does a manual sprayer play in protecting stored honeycombs? Enhance Honeycomb Longevity & Pest Protection

- What kind of damage can a mouse cause inside a beehive? Protect Your Colony's Vital Infrastructure

- What are the technical advantages of industrial electronic ozone generators for beehive sterilization? Superior Hive Hygiene

- What natural remedies can help manage hive beetles? Build a Resilient Colony for Natural Beetle Control

- Why must a Box-type dead bee collector be maintained 10 cm above ground? Ensure Accurate Hive Mortality Data

- What is the purpose of oxytetracycline in honeybee colony maintenance? Ensure Hive Stability and Research Data Integrity

- What is the function of diaphragm-type electrolyzed water equipment? High-Efficiency Disinfection for Modern Apiaries

- How do traps designed for small hive beetles function? Mastering Effective Mechanical Control