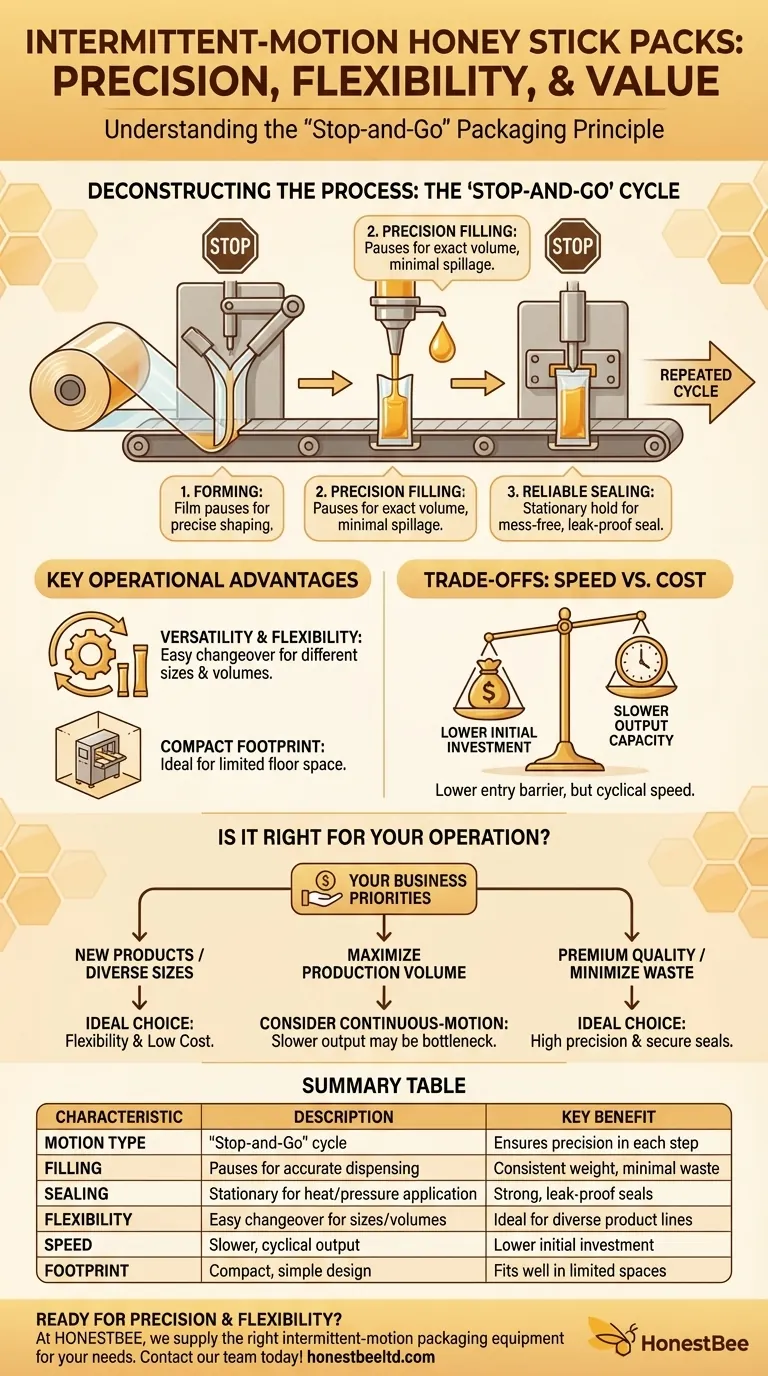

At its core, an intermittent-motion honey stick pack machine operates on a "stop-and-go" principle. The packaging film pauses momentarily for each distinct step of the process: forming the stick-shaped pouch, filling it with a precise amount of honey, and then securely sealing it. This deliberate, cyclical pausing is the defining characteristic that dictates its performance, cost, and ideal use case.

Intermittent-motion machines trade high-speed output for superior precision, operational flexibility, and a lower initial investment. They are engineered for quality and versatility, not sheer volume.

Deconstructing the Intermittent Motion Process

The value of an intermittent-motion machine is found in its methodical, step-by-step approach to packaging. Each pause in the cycle serves a specific purpose.

The "Stop-and-Go" Cycle

The machine pulls a length of packaging material, forms it, fills it, and seals it—all while the film is stationary. This "stop-and-go" sequence is repeated for every single stick, ensuring each step is completed with care before moving to the next.

High-Precision Filling

The pause during the filling stage is critical for a viscous product like honey. It allows the filling nozzle to dispense an exact volume with minimal spillage or waste, leading to consistent product weight and a clean, professional appearance.

Reliable Sealing

With the stick held stationary, the sealing jaws can apply consistent heat and pressure. This creates a perfect, mess-free seal that protects the product's integrity and prevents leaks, which is crucial for consumer trust.

Key Operational Advantages

Beyond the core process, intermittent-motion machines offer distinct benefits that make them attractive for specific business models.

Versatility and Flexibility

These machines excel at handling a variety of tasks. They are often engineered for easy changeover, allowing you to quickly switch between different stick sizes, film types, or fill volumes with minimal downtime.

Compact Footprint

The mechanical design of intermittent-motion systems is typically simpler and more compact than their high-speed counterparts. This makes them an excellent choice for facilities with limited floor space or for businesses adding a new capability to an existing production line.

Understanding the Trade-offs: Speed vs. Cost

No machine is perfect for every scenario. The primary trade-off with intermittent motion is a clear choice between production volume and financial accessibility.

Slower Output Capacity

The most significant limitation is speed. The time it takes to stop and start for every cycle naturally results in a slower overall output compared to continuous-motion machines that fill and seal while the film is constantly moving.

Lower Initial Investment

This slower, simpler mechanical process translates directly into a more affordable machine. The lower capital expenditure makes this technology highly accessible for startups, small businesses, or companies entering the honey stick market for the first time.

Is an Intermittent-Motion Machine Right for Your Operation?

Choosing the right equipment depends entirely on your business priorities and production goals.

- If your primary focus is launching a new product or handling diverse stick sizes: The excellent flexibility and lower entry cost of an intermittent-motion machine make it an ideal choice.

- If your primary focus is maximizing production volume for a single, high-demand product: The slower output may become a bottleneck, and you should investigate higher-speed continuous-motion alternatives.

- If your primary focus is premium product quality and minimizing waste: The high precision in filling and the quality of the seal provided by this process are significant, waste-reducing advantages.

Ultimately, understanding this technology empowers you to select the tool that aligns perfectly with your operational strategy and budget.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| Motion Type | "Stop-and-Go" cycle | Ensures precision in each step |

| Filling | Pauses for accurate dispensing | Consistent weight, minimal waste |

| Sealing | Stationary for heat/pressure application | Strong, leak-proof seals |

| Flexibility | Easy changeover for sizes/volumes | Ideal for diverse product lines |

| Speed | Slower, cyclical output | Lower initial investment |

| Footprint | Compact, simple design | Fits well in limited spaces |

Ready to package your honey with precision and flexibility?

At HONESTBEE, we supply the right intermittent-motion packaging equipment to help commercial apiaries and distributors launch new products, minimize waste, and maintain a lean operation. Our wholesale-focused model ensures you get reliable, high-quality beekeeping supplies and equipment at a competitive price.

Let's discuss how our solutions can fit your production line. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What are the advantages of high-precision honey-filling machines in export-oriented honey processing? Maximize Compliance

- What role do professional automated filling and packaging machines play in honey processing? Boost Efficiency & Value

- Why do organic honey and liquid foods need high-precision filling equipment for the EU? Key to Market Access

- How should cost-effectiveness be evaluated when choosing a honey packaging machine? Maximize ROI and Efficiency

- How can contamination in filled honey be prevented? Essential Safety Tips for Pure Honey Production

- What is the strategic importance of honey filling equipment? Scaling Your Commercial Bee Product Brand

- How do industrial-grade honey filling machines contribute to commercialization? Scaling Your Bee Product Business

- How do advanced honey refining and honey-filling machines contribute to large-scale commercial honey production?