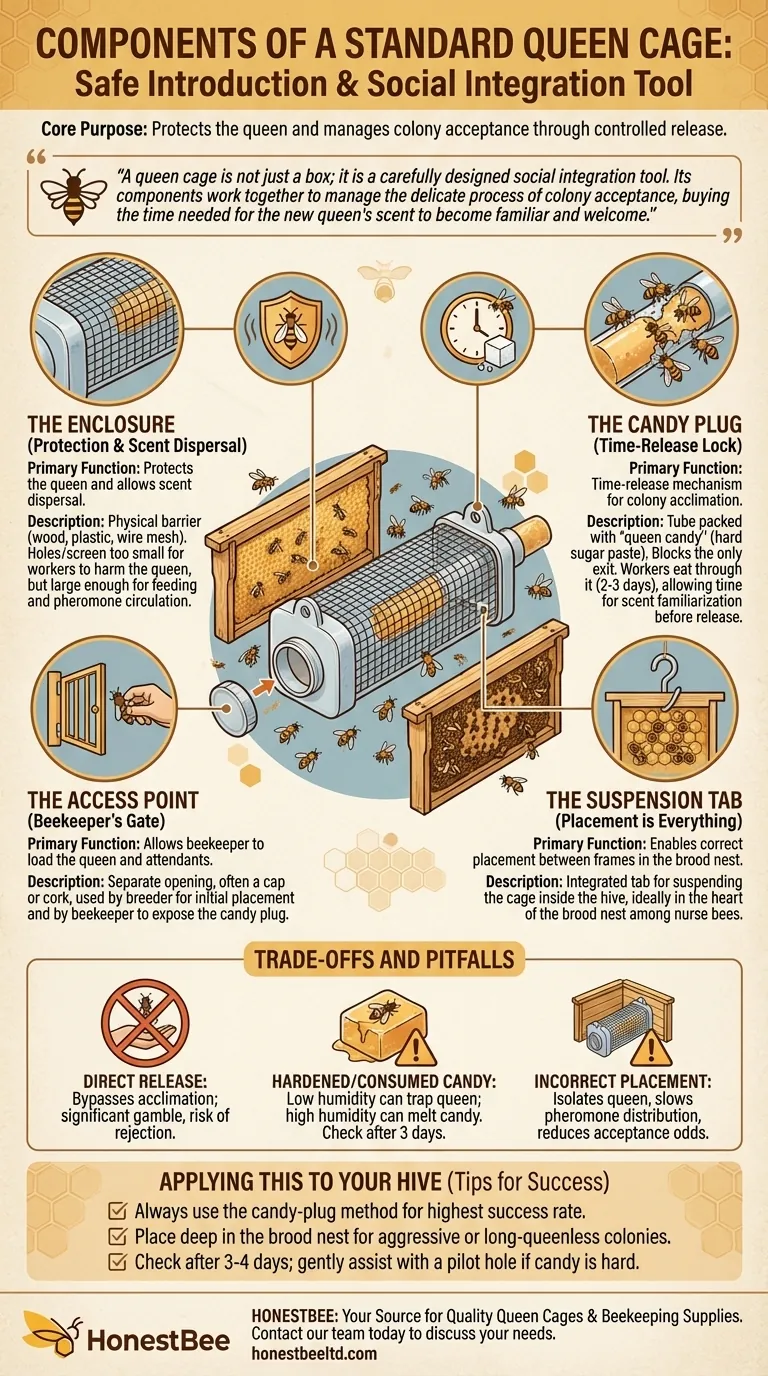

At its core, a standard queen cage is a small, protective enclosure designed for the safe introduction of a new queen bee into a colony. The primary components are the cage body, which provides a physical barrier, an access point for the beekeeper, and a special candy-filled exit hole that serves as a time-release mechanism for the queen.

A queen cage is not just a box; it is a carefully designed social integration tool. Its components work together to manage the delicate process of colony acceptance, buying the time needed for the new queen's scent to become familiar and welcome.

The Anatomy of a Queen Cage: A Functional Breakdown

To understand a queen cage, you must understand the purpose of each part. The design is entirely focused on protecting the queen from the colony's initial, predictable aggression while allowing for her eventual, safe release.

The Enclosure: Protection and Scent Dispersal

The main body of the cage physically protects the queen. While the colony is hostile to a foreign queen, worker bees will try to "ball" and kill her.

The enclosure is typically made of wood, plastic, or wire mesh. The holes or screen are large enough for worker bees to feed the queen and her attendants, but too small for them to get in and harm her. Most importantly, these openings allow the queen's unique pheromones to circulate throughout the hive.

The Candy Plug: The Time-Release Lock

This is the most critical component for a successful introduction. One end of the cage has a small tube or chamber packed with a hard sugar paste known as "queen candy."

This candy plug blocks the only exit for the queen. The worker bees on both sides of the plug will slowly eat through it. This process typically takes two to three days. This delay is the key to success, as it gives the colony enough time to acclimate to her scent and accept her as their new matriarch.

The Access Point: The Beekeeper's Gate

Separate from the candy-plugged exit, there is an access point for the beekeeper. This is often a small plastic cap or a cork.

This is how the queen and a few attendant bees are initially placed into the cage by the breeder. When you install the cage, you typically remove this cork to expose the candy plug, initiating the time-release process.

The Suspension Tab: Placement is Everything

Most modern queen cages, particularly plastic ones, have an integrated tab or hook. This is not for attaching to the hive stand, but for suspending the cage between two frames inside the hive.

Proper placement ensures the cage is in the heart of the brood nest, where the highest concentration of young "nurse" bees are. These younger bees are generally more receptive to a new queen, and their acceptance is crucial for the rest of the colony.

Understanding the Trade-offs and Pitfalls

While a simple device, improper use of a queen cage is a common reason for requeening failures. Understanding the potential issues is critical.

The Temptation of "Direct Release"

Sometimes a beekeeper will see the workers acting peacefully toward the caged queen and decide to release her manually. This is a significant gamble.

Direct release bypasses the crucial acclimation period that the candy plug provides. A colony's mood can change instantly, and releasing her even a day too early can result in her immediate rejection and death.

Hardened or Consumed Candy

If the hive has very low humidity, the candy can harden into a rock, trapping the queen. Conversely, in very high humidity, it can melt.

It is vital to check on the cage after about three days. If the bees have not released her, you may need to carefully create a very small opening in the candy to help them finish the job.

Incorrect Cage Placement

Placing the cage in the wrong part of the hive, such as the outer edges or in a honey super, isolates the queen from the core population.

This slows down pheromone distribution and dramatically reduces the odds of acceptance. The cage must be placed in the brood nest, where the bees will actively attend to her.

Applying This to Your Hive

Your goal dictates how you approach the process. Use the cage's design to your advantage.

- If your primary focus is the highest chance of success: Always use the candy-plug method and never direct release a queen on the first day. Trust the time-release mechanism.

- If you are requeening a known aggressive or long-queenless colony: Ensure you place the cage deep in the brood nest and give the bees at least three full days before you check on the release.

- If you are checking on the release after 3-4 days: Come prepared to intervene gently. If the candy is hard, use a small nail to create a tiny pilot hole for the bees to work on.

Understanding that a queen cage is a tool for managing social chemistry, not just a container, is the key to successfully requeening your colony.

Summary Table:

| Component | Primary Function |

|---|---|

| Enclosure | Protects the queen and allows scent dispersal. |

| Candy Plug | Time-release mechanism for colony acclimation. |

| Access Point | Allows beekeeper to load the queen and attendants. |

| Suspension Tab | Enables correct placement between frames in the brood nest. |

Ready to ensure a successful requeening? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the highest-quality, reliable queen cages and other essential beekeeping supplies. Our wholesale-focused operations ensure you get the equipment you need to protect your most valuable assets. Contact our team today to discuss your needs and secure your supplies.

Visual Guide

Related Products

- Professional Multi-Functional Queen Bee Cage

- Multi-Function Queen Roller Cage and Catcher

- Durable Galvanized Steel Spring Queen Bee Cage

- Professional Multi-Compartment Queen Cage with Sliding Lid

- Wood and Mesh Push-In Queen Cage

People Also Ask

- What is the function of queen cages? Protect Your New Queen Bees and Improve Colony Integration Success

- How should a queen cage be managed and maintained? Essential Tips for Commercial Apiaries

- How does queen candy facilitate the safe release of a queen bee? Master the Art of Successful Colony Integration

- How do queen cages like the JZBZ model facilitate the safe introduction of a queen? Master Queen Acceptance Techniques

- How can a beekeeper improve nurse bee access to queen cages in a bank? Optimize Hive Space for Queen Health