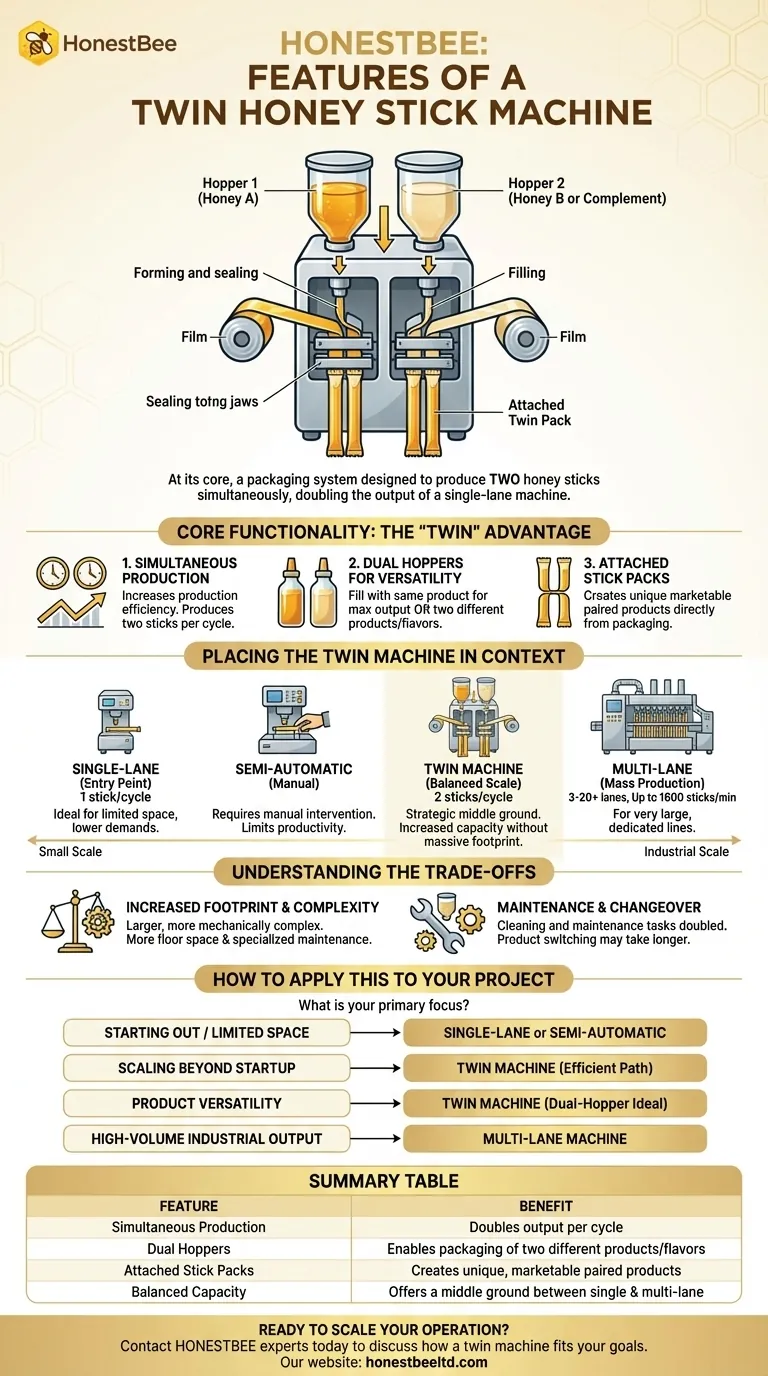

At its core, a twin honey stick machine is a packaging system designed to produce two honey sticks simultaneously. This is achieved through a design that incorporates two separate product hoppers, allowing it to form, fill, and seal two attached stick packs in a single cycle, effectively doubling the output of a single-lane machine.

The decision to use a twin honey stick machine is not just about doubling speed. It represents a strategic choice for businesses looking to scale production efficiently while retaining the unique flexibility to package complementary products or flavors simultaneously.

Core Functionality: The "Twin" Advantage

A twin machine's primary benefit comes from its dual-path architecture. This design unlocks specific capabilities that set it apart from other machine types.

Simultaneous Production

The most obvious feature is its ability to produce two honey sticks at the same time. This immediately increases production efficiency and throughput compared to a machine that only produces one stick per cycle.

Dual Hoppers for Versatility

The machine is equipped with two product hoppers. This is a critical feature. You can fill both hoppers with honey to maximize output, or you can fill them with two different products, such as honey in one and a complementary product like tea or a different flavor in the other.

Attached Stick Packs

Often, the machine creates a "twin pack" where the two sticks are attached. This can be a unique marketing feature, offering customers a paired product experience directly from the packaging.

Placing the Twin Machine in Context

To understand the value of a twin machine, it's essential to compare it to the other options available in the market.

Compared to Single-Lane Machines

A single-lane machine is the entry point, designed with one lane to produce one honey stick per cycle. It is smaller and ideal for operations with limited space or lower production demands. A twin machine is the logical step up when production needs to scale beyond this.

Compared to Multi-Lane Machines

Multi-lane machines are built for mass production, featuring anywhere from three to over twenty lanes. These industrial-scale systems can produce up to 1,600 sticks per minute and are suited for very large, dedicated production lines. A twin machine fits a middle ground, offering increased capacity without the massive footprint and investment of a full multi-lane system.

Compared to Semi-Automatic Machines

A semi-automatic machine requires manual operator intervention, such as loading the film roll or removing finished sticks. This limits productivity and is best for small-scale businesses. A twin machine is typically fully automated, handling the entire process seamlessly for much higher output.

Understanding the Trade-offs

While offering clear benefits, a twin machine also comes with considerations that must be weighed against your operational goals.

Increased Footprint and Complexity

Naturally, a machine with two filling and sealing lines is larger and more mechanically complex than a single-lane model. This requires more floor space and potentially more specialized maintenance.

Balancing Capacity and Cost

A twin machine offers a significant boost in output over a single-lane machine. However, it represents a higher capital investment. It is more productive but falls short of the massive throughput of a multi-lane machine, which comes at a much higher price point.

Maintenance and Changeover

With two hoppers and two sets of forming, filling, and sealing components, cleaning and maintenance tasks are doubled compared to a single-lane machine. Switching products or packaging sizes may also take more time.

How to Apply This to Your Project

Your choice of machine should be dictated by your specific production volume, product strategy, and available resources.

- If your primary focus is starting out or have limited space: A single-lane or semi-automatic machine offers the lowest barrier to entry.

- If your primary focus is scaling beyond a startup level: The twin machine provides a clear and efficient path to doubling your production capacity.

- If your primary focus is product versatility: The twin machine's dual-hopper system is uniquely ideal for packaging paired products or two different flavors at once.

- If your primary focus is high-volume industrial output: A dedicated multi-lane machine is the only solution that will meet your throughput demands.

Ultimately, selecting the right machine is about precisely matching its capabilities to your business's current needs and future ambitions.

Summary Table:

| Feature | Benefit |

|---|---|

| Simultaneous Production | Doubles output per cycle compared to single-lane machines. |

| Dual Hoppers | Enables packaging of two different products or flavors at once. |

| Attached Stick Packs | Creates unique, marketable paired products for customers. |

| Balanced Capacity | Offers a middle ground between single-lane and large multi-lane systems. |

Ready to scale your honey packaging operation with precision?

A twin honey stick machine from HONESTBEE is the ideal solution for commercial apiaries and beekeeping equipment distributors looking to efficiently increase production capacity and explore new product offerings. Our wholesale-focused operations ensure you get robust, reliable equipment designed for your growth.

Contact our experts today to discuss how a twin machine can fit your specific production goals and unlock new versatility for your brand.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- Why use professional industrial honey-filling machines? Boost Your Production Efficiency and Market Reach

- What is the industrial value of professional honey filling and processing machinery? Maximize Your Market Value

- What role do automated honey filling machines play in the honey value chain? Elevate Your Apiary's Commercial Success

- What are the benefits of using a phenology-based prediction system? Boost Honey Processing & Filling Efficiency

- What technical advantages do precision honey filling machines provide? Optimize Your Honey Packaging Workflow

- What features should be compared when selecting a honey stick machine? A Guide to Maximizing Your Production Efficiency

- Why is high-performance honey filling and packaging equipment essential? Boost Efficiency & Brand Value

- How does a jar or bottle packing machine function? Automate Your Packaging Line for Precision and Speed