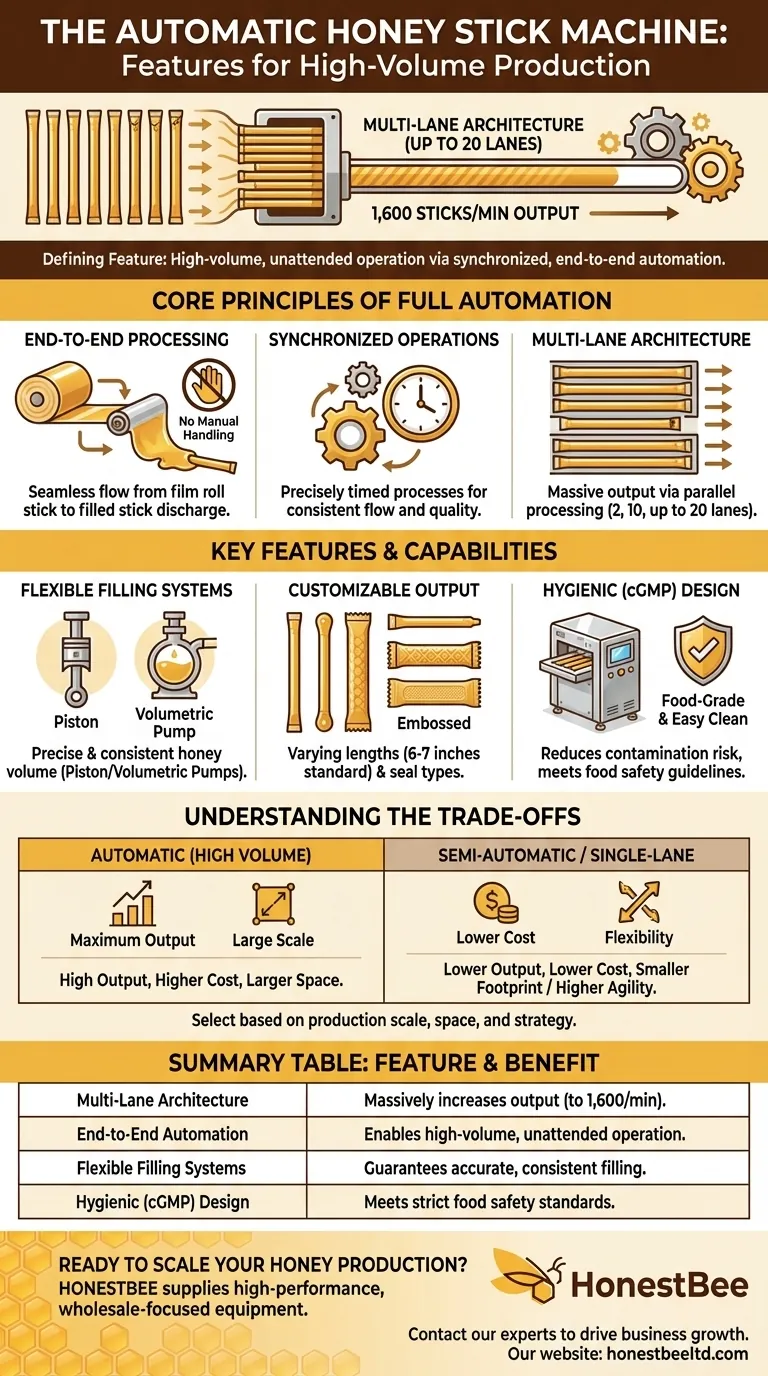

The defining feature of an automatic honey stick machine is its capacity for high-volume, unattended operation. Unlike other models, a fully automatic machine manages the entire packaging process—from forming and filling to sealing and cutting—across multiple lanes simultaneously. This end-to-end automation makes it the standard for large-scale commercial production.

The term "automatic" signifies more than just speed; it points to a machine built for a specific operational scale. Its core features are a multi-lane architecture and fully synchronized processes, designed to maximize output with minimal manual intervention.

The Core Principles of Full Automation

An automatic honey stick machine is engineered as a complete, integrated system. Its design is based on three core principles that enable high-volume output.

End-to-End Processing

A truly automatic machine requires no manual handling during a production cycle. It seamlessly integrates every step, from feeding the packaging film to discharging the finished, sealed honey sticks.

This contrasts sharply with semi-automatic models, which require an operator to manually load materials and remove the final product.

Synchronized Operations

Every action within the machine is precisely timed and synchronized. The processes of forming the stick shape, filling it with a precise volume of honey, and then sealing both ends happen in a continuous, coordinated flow.

This synchronization is critical for maintaining consistency and achieving high speeds without errors.

Multi-Lane Architecture

The most significant feature is the use of multiple production lanes. While a single-lane machine produces one stick per cycle, an automatic machine can have two, ten, or even up to 20 lanes working in parallel.

This architecture is what allows for massive outputs, with some high-end models producing as many as 1,600 honey sticks per minute.

Key Features and Capabilities

Beyond its core operating principles, several key features define the functionality and value of an automatic honey stick machine.

Flexible Filling Systems

These machines are typically equipped with advanced piston and volumetric pumps. This technology ensures that a precise, consistent amount of honey is dispensed into every stick, which is critical for quality control and cost management.

Customizable Output

While designed for scale, automatic machines still offer flexibility. They can be configured to produce honey sticks of varying lengths, though the standard is 6-7 inches.

Furthermore, the sealing mechanism can be customized to create different styles, including standard flat seals, patterned seals, or even embossed logos for branding.

Hygienic and cGMP-Compliant Design

Given that honey is a food product, hygiene is paramount. Automatic machines are built to reduce the risk of contamination, often adhering to cGMP (current Good Manufacturing Practice) guidelines. This includes using food-grade materials and ensuring easy accessibility for cleaning.

Understanding the Trade-offs

Choosing an automatic machine involves understanding its specific advantages and limitations compared to other available models.

Automatic vs. Semi-Automatic

The primary trade-off is between productivity and cost. An automatic machine offers maximum output for large-scale operations. A semi-automatic machine has a much lower output but is a more suitable investment for small or medium-sized businesses due to its lower cost and smaller footprint.

Multi-Lane vs. Single-Lane

The decision here is based on scale versus flexibility. A multi-lane machine is built for one purpose: mass production. In contrast, a single-lane machine offers lower capacity but often allows for faster changeovers to produce sticks of different lengths or styles, making it better for specialized or varied product lines.

Space and Infrastructure Requirements

The size and complexity of a multi-lane automatic machine mean it requires significantly more floor space for setup and operation. This is a practical constraint that often dictates the feasibility of adopting such a system.

Selecting the Right Machine for Your Production Scale

The right choice is not about which machine is "best," but which is best suited to your operational goals.

- If your primary focus is large-scale, high-volume production: An automatic, multi-lane machine is the only viable option to achieve the necessary speed and efficiency.

- If your primary focus is small to medium-sized batches: A semi-automatic or single-lane machine provides a much better balance of cost, space, and manageable productivity.

- If your primary focus is product variety and frequent changeovers: A single-lane machine's agility in changing parts to produce different stick lengths makes it the most flexible choice.

Ultimately, your decision should be guided by a clear assessment of your production volume, available space, and long-term business strategy.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Multi-Lane Architecture | Multiple lanes (up to 20) operate in parallel. | Massively increases output, up to 1,600 sticks/min. |

| End-to-End Automation | Fully integrated process from forming to sealing. | Enables high-volume, unattended operation. |

| Synchronized Operations | All processes are precisely timed and coordinated. | Ensures consistent quality and high-speed production. |

| Flexible Filling Systems | Uses precise piston and volumetric pumps. | Guarantees accurate, consistent filling for every stick. |

| Hygienic (cGMP) Design | Built with food-grade materials for easy cleaning. | Meets strict food safety standards for honey packaging. |

Ready to Scale Your Honey Production?

For commercial apiaries and beekeeping equipment distributors, an automatic honey stick machine is the key to unlocking unprecedented efficiency and output. HONESTBEE supplies the high-performance, wholesale-focused equipment you need to meet large-scale demand.

Contact our experts today to discuss how our automatic honey stick machines can transform your packaging line and drive your business growth.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What challenges do high-efficiency honey filling machines address? Optimize Your Export Standards and Profitability

- How does professional honey filling and packaging enhance market competitiveness? Boost Brand Value and Retail Power

- What is a honey stick packing machine? Master the Operational Process for Efficient Packaging

- What are some common types of honey packaging machines? Choose the Right One for Your Operation

- Why are high-precision honey filling machines and labeling equipment necessary for the commercialization of stingless bee honey?

- How does automated honey filling equipment contribute to international standards for honeydew honey exports?

- How do honey filling machines ensure product quality? Precision Technology for Large-Scale Beekeeping Success

- What function do professional filtration and filling units serve in honey processing? Scale Your Quality Control