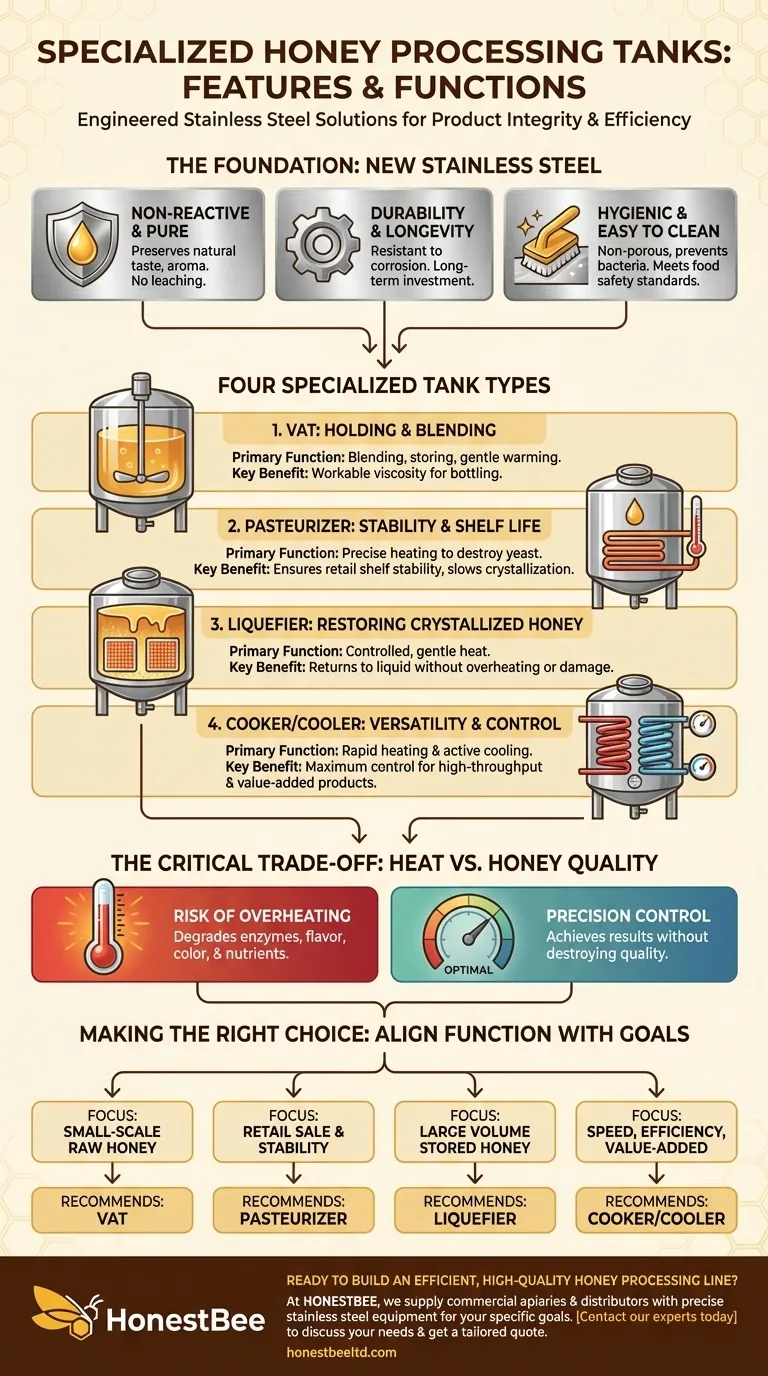

At their core, the processing tanks offered are specialized tools for key stages of honey production, including vats, pasteurizers, liquefiers, and cooker/coolers. All units are constructed from new stainless steel, ensuring they meet the stringent requirements for food-grade processing and product integrity.

The key is not just knowing the types of tanks available, but understanding that each one performs a distinct function. Selecting the right tank depends entirely on your specific goal, whether it's simply storing honey, preparing it for retail, or restoring it from a crystallized state.

The Role of Stainless Steel in Honey Processing

The use of new stainless steel is a critical feature, not a minor detail. This material is the industry standard for handling honey for several essential reasons.

Non-Reactive and Pure

Honey is naturally acidic. Stainless steel is non-reactive, meaning it will not leach metals or other compounds into the honey, preserving its natural taste, aroma, and purity.

Durability and Longevity

Stainless steel is exceptionally strong and resistant to corrosion and rust. This ensures a long service life for the equipment, representing a sound long-term investment for any processing operation.

Hygienic and Easy to Clean

The smooth, non-porous surface of stainless steel prevents bacteria from harboring and makes the tanks easy to sanitize. This is non-negotiable for meeting food safety standards and producing a safe, high-quality product.

A Closer Look at Each Processing Tank

Each tank is engineered to solve a specific problem in the honey processing workflow. Understanding their individual purpose is the first step toward building an efficient system.

The Vat: For Holding and Blending

A vat is the most fundamental tank. Its primary purpose is for holding, storing, and blending honey. It can be used to mix honey from different floral sources or to gently warm the honey to a more workable viscosity before bottling.

The Pasteurizer: For Stability and Shelf Life

A pasteurizer is designed to heat honey to a precise temperature for a specific duration. This process destroys osmophilic yeasts that can cause fermentation, making the honey shelf-stable for retail environments. It also slows down the natural process of crystallization.

The Liquefier: For Restoring Crystallized Honey

Crystallization is a natural process in raw honey. A liquefier (or decrystallizer) uses gentle, controlled heat to melt the glucose crystals, returning the honey to a smooth liquid state without overheating and damaging its delicate enzymes and flavor compounds.

The Cooker/Cooler: For Versatility and Control

A cooker/cooler offers the most advanced functionality. It can rapidly heat honey for pasteurization or for creating infused honey products, and then actively cool it down to stop the cooking process. This provides maximum control and is ideal for high-throughput or specialized production.

Understanding the Trade-offs: Heat and Honey Quality

The primary trade-off in honey processing involves heat. While necessary for liquefying and pasteurizing, applying too much heat—or applying it for too long—can be detrimental.

The Risk of Overheating

Excessive heat degrades the natural enzymes, vitamins, and delicate aromatic compounds that make honey a premium product. This can negatively affect its flavor, color, and nutritional value.

The Need for Precision Control

Specialized equipment like pasteurizers and liquefiers is valuable precisely because it allows for controlled heating. The goal is to apply just enough heat to achieve the desired result (e.g., melting crystals) without "cooking" the honey and destroying its quality.

Making the Right Choice for Your Operation

Choosing the right tank requires aligning the equipment's function with your business goals.

- If your primary focus is small-scale bottling of raw honey: A simple stainless steel vat for blending and settling may be all you require.

- If your primary focus is preparing honey for retail sale: A pasteurizer is essential to ensure shelf stability and prevent fermentation.

- If your primary focus is handling large volumes of stored honey: A dedicated liquefier is a crucial tool for efficiently reliquefying honey that has crystallized in bulk containers.

- If your primary focus is speed, efficiency, or creating value-added products: A cooker/cooler provides the precise control needed for complex processes and high-throughput operations.

Ultimately, selecting the correct processing tank is an investment in protecting the quality and maximizing the value of your final product.

Summary Table:

| Tank Type | Primary Function | Key Benefit |

|---|---|---|

| Vat | Holding, Storing, Blending | Gentle warming for workable viscosity |

| Pasteurizer | Ensuring Shelf Stability | Destroys yeast, slows crystallization |

| Liquefier | Restoring Crystallized Honey | Gentle, controlled heating |

| Cooker/Cooler | Rapid Heating & Active Cooling | Maximum control for high-throughput |

Ready to build an efficient, high-quality honey processing line?

At HONESTBEE, we supply commercial apiaries and distributors with the precise stainless steel equipment needed to protect your product's integrity. From durable vats for blending to advanced cooker/coolers for value-added products, our wholesale-focused operations deliver the right tools for your specific goals.

Contact our experts today to discuss your needs and get a quote tailored to your operation.

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What are the multipurpose functionalities of a honey press? Versatile Harvesting for Beekeepers & Homesteaders

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- Why is the use of standardized honey harvesting tools critical? Enhance Purity and Colony Health in Your Apiary

- How can a honey press be used beyond honey extraction? Unlock Its Full Potential for Your Farm

- How easy is it to clean and maintain the Honey Press? Designed for Quick, Effortless Cleanup