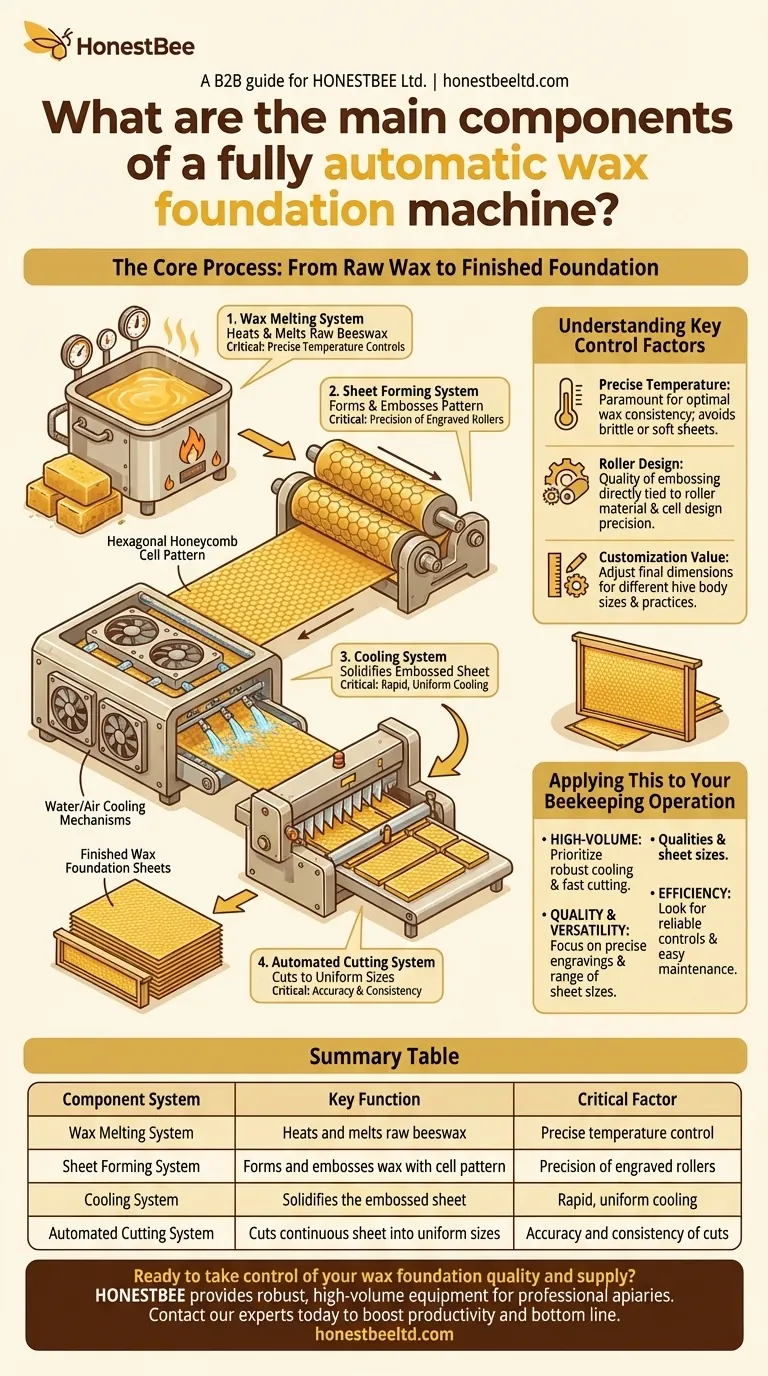

At its core, a fully automatic wax foundation machine is comprised of four integrated systems that work in sequence. These are the wax melting system, the sheet forming system with its embossed rollers, the cooling system, and the automated cutting system. Together, they transform raw beeswax into perfectly patterned and sized foundation sheets ready for the hive.

Understanding these components is not just about knowing the parts of a machine; it's about understanding the entire process of creating high-quality, consistent beeswax foundation, which is fundamental to modern beekeeping efficiency.

The Process: From Raw Wax to Finished Foundation

A fully automatic machine streamlines what was once a multi-step, labor-intensive process. The wax follows a precise journey through several key stages, each managed by a specific component group.

The Wax Melting System: The Starting Point

The process begins by melting raw blocks of beeswax. This system is essentially a heated vat or tank designed for this purpose.

It is equipped with precise temperature controls. Maintaining the correct temperature is critical; if the wax is too hot, its natural properties can be damaged, but if it's too cool, it won't flow properly into the next stage.

The Sheet Forming System: Creating the Pattern

This is the heart of the machine. The molten wax flows onto a set of two counter-rotating rollers that are fixed horizontally and close together.

The surface of these rollers is engraved with the hexagonal honeycomb cell pattern. As the wax passes between them, it is simultaneously cooled into a thin sheet and embossed with this essential cell base on both sides.

The Cooling System: Solidifying the Sheet

As the newly formed, embossed sheet of wax emerges from the rollers, it needs to be solidified quickly to maintain its shape and pattern integrity.

This is often achieved with integrated water or air cooling mechanisms. The cooling system ensures the wax is firm enough to be handled by the cutting system without distortion.

The Cutting System: Finalizing the Product

The final stage involves cutting the continuous ribbon of wax foundation into individual, uniform sheets.

An automated cutting mechanism, typically using sharp blades, cuts the sheets to a pre-set length. This ensures every foundation sheet is consistent and ready for placement into a hive frame.

Understanding the Key Control Factors

The quality of the final product depends on more than just the components themselves; it relies on how well their functions are controlled and calibrated.

The Importance of Precise Temperature

As mentioned, temperature is paramount. Inconsistent heat in the melting tank or improper cooling can lead to brittle foundation that cracks easily or soft foundation that sags in the hive.

A high-quality machine will maintain a stable temperature throughout the process, ensuring optimal wax consistency.

The Role of Roller Design

The quality of the embossing is directly tied to the rollers. These are typically made from cast iron or another durable metal.

The precision of the cell design engraved on the rollers determines how well the bees will accept and draw out the comb. Misalignment can cause thin spots or an incomplete pattern.

The Value of Customization

Modern machines offer the ability to adjust the final dimensions of the wax sheets. This is not a minor feature.

This flexibility allows a beekeeper or supplier to produce foundation for different hive body sizes (e.g., Langstroth deep, medium, or shallow) or for specific beekeeping practices, maximizing the machine's utility.

Applying This to Your Beekeeping Operation

Choosing or operating a machine requires matching its capabilities to your specific goals.

- If your primary focus is high-volume production: Prioritize a machine with a robust cooling system and a fast, reliable cutting mechanism to maximize output per hour.

- If your primary focus is quality and versatility: Pay close attention to the precision of the roller engravings and the range of customization options for sheet size.

- If your primary focus is operational efficiency: Look for a machine with reliable, easy-to-use temperature controls and a design that simplifies cleaning and maintenance.

Ultimately, a fully automatic wax foundation machine empowers you to control the quality and supply of the very base of your honeycombs.

Summary Table:

| Component System | Key Function | Critical Factor |

|---|---|---|

| Wax Melting System | Heats and melts raw beeswax | Precise temperature control |

| Sheet Forming System | Forms and embosses wax with cell pattern | Precision of engraved rollers |

| Cooling System | Solidifies the embossed sheet | Rapid, uniform cooling |

| Automated Cutting System | Cuts continuous sheet into uniform sizes | Accuracy and consistency of cuts |

Ready to take control of your wax foundation quality and supply?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the robust, high-volume equipment you need to maximize efficiency and ensure consistent, high-quality foundation production. Our machines are engineered for the demands of professional beekeeping operations.

Contact our experts today to discuss how our fully automatic wax foundation machines can be integrated into your operation to boost your productivity and bottom line.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Mini Desktop Bee Hive Frame Forming Making Machine

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction