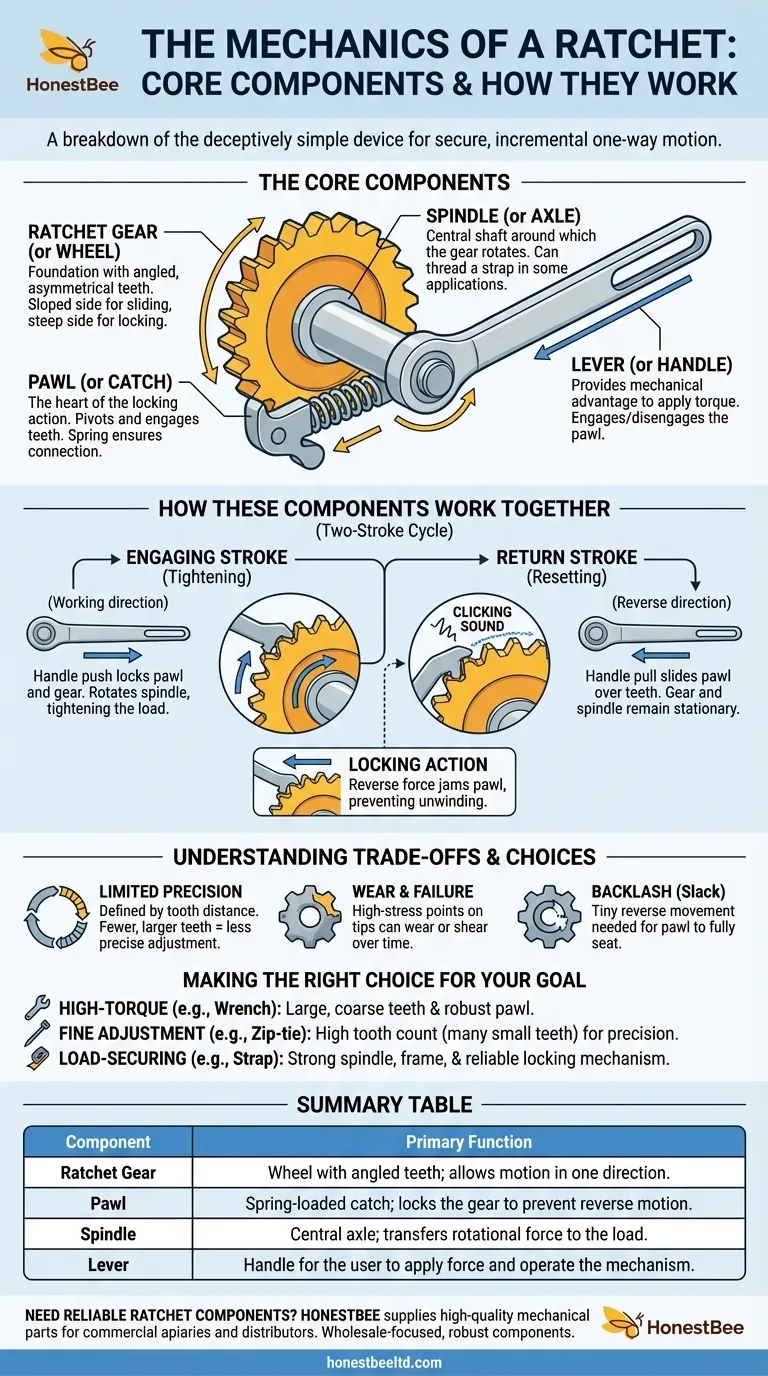

At its core, a ratchet mechanism is a deceptively simple device built from two primary components: a toothed ratchet gear and a pivoting catch called a pawl. These parts work together with a spindle, which serves as the axle, and a handle or lever that provides the force needed to operate the system.

The fundamental purpose of a ratchet is to permit significant rotational or linear motion in one direction while completely preventing motion in the opposite direction, creating a secure, incremental lock.

The Core Components in Detail

To truly understand how a ratchet functions, we must examine the specific role each part plays in this mechanical interaction.

The Ratchet Gear (or Wheel)

The ratchet gear is the foundation of the mechanism. It is a wheel or bar with angled, asymmetrical teeth.

The sloped side of each tooth allows the pawl to slide over it, while the steep, near-vertical side is designed to catch and block the pawl.

The Pawl (or Catch)

The pawl is the heart of the locking action. It is a small, spring-loaded lever designed to pivot and engage with the teeth of the ratchet gear.

The spring ensures the pawl is always pushed toward the gear, guaranteeing it will fall into place behind a tooth to prevent backward movement.

The Spindle (or Axle)

The spindle is the central shaft around which the ratchet gear rotates.

In applications like a tie-down strap, this spindle often has a slot through which the strap is threaded, allowing it to be wound tightly as the mechanism is operated.

The Lever (or Handle)

The lever provides the user with the mechanical advantage needed to apply torque and turn the spindle.

As the handle is moved back and forth, it engages and disengages the pawl with the gear, creating the signature ratcheting action.

How These Components Work Together

The genius of the ratchet is in the coordinated movement of its parts during a two-stroke cycle.

The Engaging Stroke (Tightening)

When you push the handle in the "working" direction, the pawl engages a steep face of a gear tooth. This locks the handle and gear together, forcing the entire spindle to rotate and tighten the strap or socket.

The Return Stroke (Resetting)

When you pull the handle in the reverse direction, the pawl pivots slightly and slides up and over the sloped side of the gear teeth. You'll hear the characteristic "clicking" sound as this happens.

During this return stroke, the gear and spindle remain completely stationary, held in place by a second, fixed pawl or by the tension on the system.

The Locking Action

At any point, if a reverse force is applied to the gear (e.g., tension from a strap), that force pushes the steep side of a tooth directly against the pawl. This jams the pawl firmly in place, completely preventing the mechanism from unwinding.

Understanding the Trade-offs

While incredibly effective, the design of a ratchet mechanism comes with inherent limitations that are important to recognize.

Limited Rotational Precision

The smallest possible amount of rotation is defined by the distance between the teeth on the gear. A mechanism with fewer, larger teeth will be very strong but offer less precise adjustment.

Potential for Wear and Failure

The tips of the pawl and the gear teeth are high-stress points. Over time, or under extreme load, these points can wear down or shear off, causing the mechanism to slip or fail. The quality of the materials used is paramount.

The "Backlash" or Slack

There is a tiny amount of reverse movement required for the pawl to fully seat against the face of a gear tooth. This small bit of slack is known as backlash and is present in nearly all ratchet designs.

Making the Right Choice for Your Goal

Understanding these components allows you to select the right tool for the job based on its specific design characteristics.

- If your primary focus is high-torque applications (like a socket wrench): You need a mechanism with large, coarse teeth and a robust, hardened steel pawl that can withstand immense force.

- If your primary focus is fine adjustment (like in a zip-tie or scientific instrument): You should look for a mechanism with a high tooth count (many small teeth) for greater precision with every click.

- If your primary focus is load-securing (like a ratchet strap): The critical features are the strength of the spindle, the frame, and a reliable locking mechanism that will not accidentally release under load.

By recognizing how these simple parts interact, you can fully leverage the power and security that a ratchet mechanism provides.

Summary Table:

| Component | Primary Function |

|---|---|

| Ratchet Gear | Wheel with angled teeth; allows motion in one direction. |

| Pawl | Spring-loaded catch; locks the gear to prevent reverse motion. |

| Spindle | Central axle; transfers rotational force to the load. |

| Lever | Handle for the user to apply force and operate the mechanism. |

Need reliable ratchet components for your equipment? HONESTBEE supplies high-quality beekeeping supplies and equipment, including durable mechanical parts built for commercial apiaries and distributors. Our wholesale-focused operations ensure you get the robust components you need. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Professional Durable Two-Piece Plastic Bee Escape

- Multi-Functional Sliding Hive Entrance for Beekeeping

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Stainless Steel Beekeeping Honey Extractor Lid

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What is the purpose of a bee escape board? A Gentle, Chemical-Free Way to Harvest Honey

- How is an escape board constructed? A Guide to Gentle, Chemical-Free Honey Harvesting

- How does an escape board function as a bee removal tool during honey harvesting? Simplify Your Harvest Workflow

- How does an escape board work? A Gentle, Bee-Friendly Method for Harvesting Honey

- How can bees be cleared off honey supers in a Langstroth hive? Use a Gentle Bee Escape