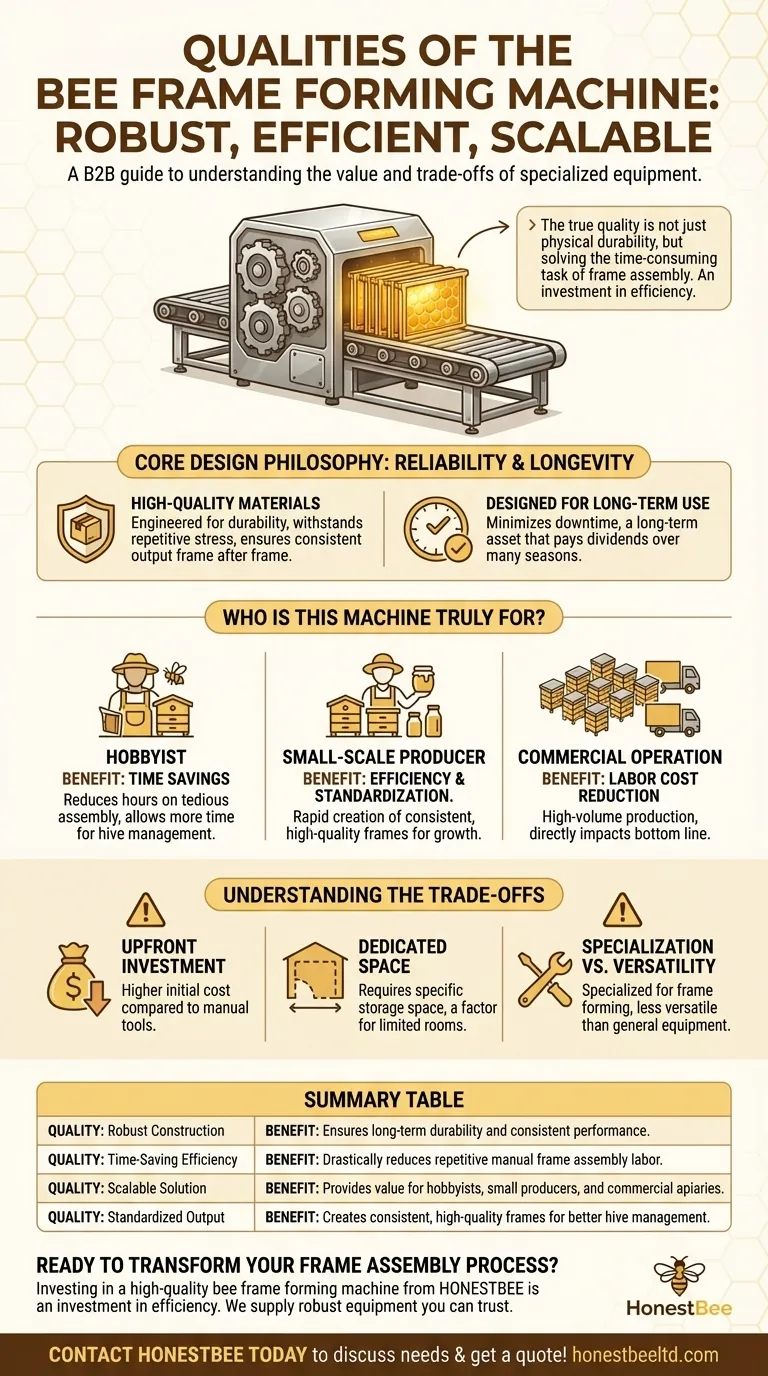

At its core, a bee frame forming machine is defined by its robust construction and specialized purpose. It is engineered from high-quality materials to ensure it is a reliable and durable tool, capable of providing consistent, long-term performance for beekeepers.

The true quality of this machine is not just its physical durability, but its ability to solve a universal beekeeping problem: the time-consuming and repetitive task of frame assembly. It's an investment in efficiency for operations of any size.

The Core Design Philosophy: Reliability and Longevity

The fundamental purpose of a specialized machine is to perform a single task exceptionally well, repeatedly. The design of a bee frame forming machine reflects this principle through its focus on durability.

High-Quality Materials

The machine is constructed from high-quality materials. This is not just for show; it ensures the equipment can withstand the repetitive stress of forming frames and the typical environment of a workshop.

This choice of materials directly translates to a more reliable and consistent output, frame after frame.

Designed for Long-Term Use

This tool is intentionally designed as a long-term asset. For a beekeeper, this means the initial investment is expected to pay dividends over many seasons of use.

A durable build minimizes the risk of downtime from equipment failure, which is critical during the busy seasons when frames are needed most.

Who is This Machine Truly For?

While the machine serves a single function, its value proposition changes depending on the scale of the beekeeping operation. It is designed to be a scalable solution.

For the Hobbyist

For the hobbyist with a few hives, the primary benefit is time. The machine drastically reduces the hours spent on the tedious task of frame assembly, allowing more time to be spent on hive management and observation.

For the Small-Scale Producer

For a sideline beekeeper or small honey producer, the machine introduces efficiency and standardization. It allows for the rapid creation of consistent, high-quality frames, which is essential for managing a growing number of hives effectively.

For the Commercial Operation

In a commercial setting, this machine becomes a vital piece of capital equipment. Its main quality is its ability to reduce labor costs and enable high-volume production, directly impacting the operation's bottom line.

Understanding the Trade-offs

No tool is without its considerations. An objective evaluation requires acknowledging the trade-offs associated with investing in specialized equipment.

The Upfront Investment

The most obvious trade-off is the initial cost. A dedicated machine requires a greater financial outlay than simple hand tools or basic jigs used for manual assembly.

The Need for Dedicated Space

Unlike a hammer and nails, this is a piece of machinery that requires dedicated storage space in a workshop. For those with limited room, this can be a significant factor.

Specialization vs. Versatility

This machine does one job: form bee frames. Its strength is its specialization. However, it cannot be repurposed for other tasks, making it a less versatile tool than general workshop equipment.

Making the Right Choice for Your Goal

Your decision to invest should be based on your specific operational needs and long-term goals.

- If your primary focus is time savings for a personal hobby: This machine eliminates one of the most repetitive chores in beekeeping.

- If your primary focus is scaling a small business: This tool provides the efficiency and standardization you need to grow your hive count without a proportional increase in labor.

- If your primary focus is minimizing commercial production costs: This machine is a direct investment in reducing labor hours and maximizing your output of essential hive components.

Ultimately, a bee frame forming machine transforms frame assembly from a potential bottleneck into a streamlined part of your beekeeping workflow.

Summary Table:

| Quality | Benefit |

|---|---|

| Robust Construction | Ensures long-term durability and consistent performance. |

| Time-Saving Efficiency | Drastically reduces repetitive manual frame assembly labor. |

| Scalable Solution | Provides value for hobbyists, small producers, and commercial apiaries. |

| Standardized Output | Creates consistent, high-quality frames for better hive management. |

Ready to Transform Your Frame Assembly Process?

Investing in a high-quality bee frame forming machine from HONESTBEE is an investment in the efficiency and scalability of your operation. Whether you are a commercial apiary looking to cut labor costs or a beekeeping equipment distributor seeking reliable wholesale supplies, our durable machines are designed to be a long-term asset that pays for itself.

We supply the robust, efficient equipment that beekeepers trust. Let us help you streamline your workflow and maximize your output.

Contact HONESTBEE today to discuss your needs and get a quote!

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

People Also Ask

- What is the purpose of a small desktop bee frame forming machine? Automate Frame Assembly for Beekeepers

- What reliability and support are offered with the Beehive Frame Making Machine? Secure Your Production Investment

- How does the Beehive Frame Making Machine allow for customizable frame production? Precision Woodworking for Apiaries

- How should the working area be prepared before making Langstroth beehive frames? Optimize Your Frame Assembly Workflow

- What is the contribution of industrial woodworking machinery to the beehive industry? Empower Your Local Supply Chain