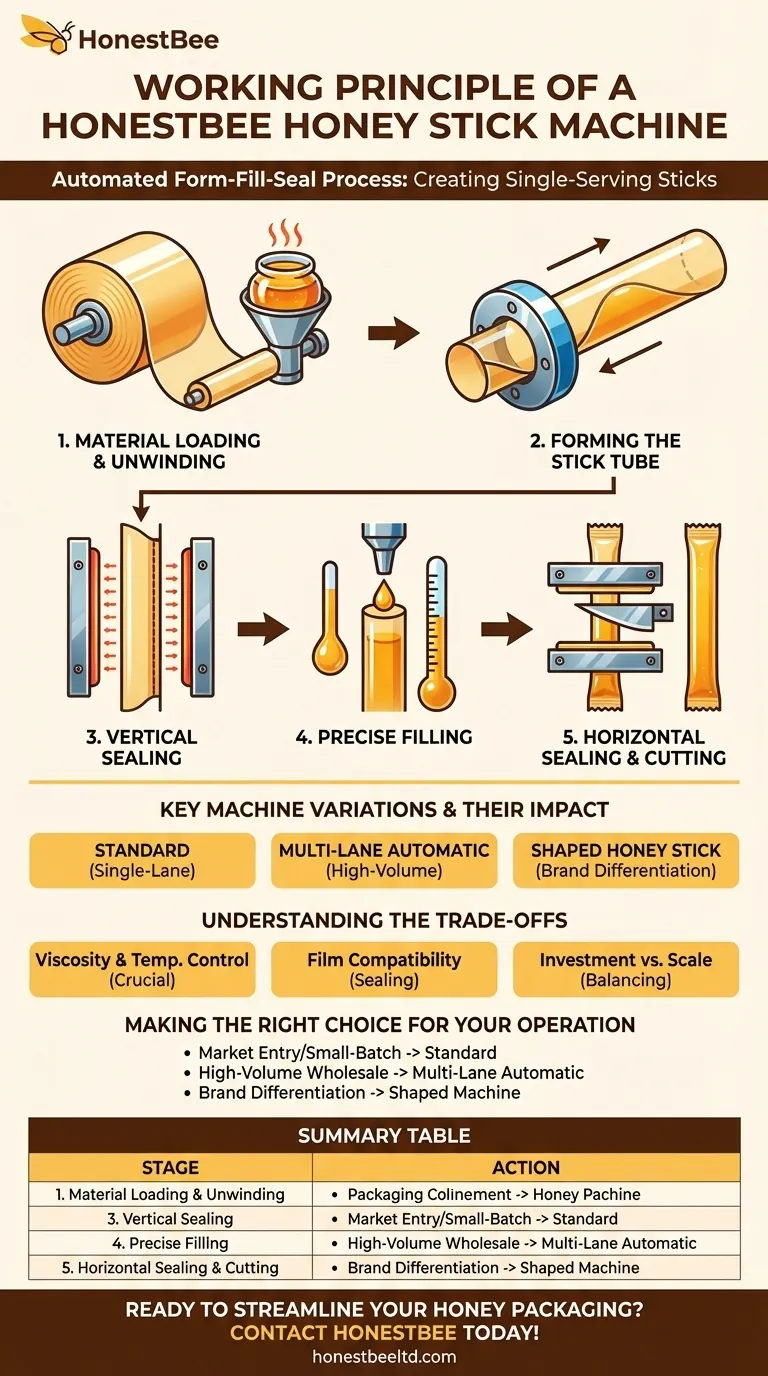

The working principle of a honey stick machine is a highly synchronized, automated process that transforms a flat roll of packaging film and a reservoir of honey into precisely sealed, single-serving sticks. This operation revolves around a core sequence of forming the packaging tube, filling it with a precise dose of honey, and then sealing and cutting it into individual units.

At its core, a honey stick machine isn't just a filler; it's a sophisticated "form-fill-seal" (FFS) system. The critical insight is understanding how it simultaneously creates the package from flat film, injects a product, and seals the final unit in one continuous, high-speed motion.

The Step-by-Step Mechanical Process

Each stage of the honey stick machine's operation is meticulously timed to ensure accuracy, efficiency, and a consistent final product. The process flows from raw materials to finished goods in a seamless, linear progression.

Stage 1: Material Loading and Unwinding

First, a large roll of packaging film is mounted onto a spindle at the back of the machine. The honey is loaded into a heated hopper. The machine then begins to unwind the flat film, feeding it into the forming section.

Stage 2: Forming the Stick Tube

The unwound flat film is pulled over a specialized forming tube or collar. This action forces the flat sheet to wrap around the tube, creating the familiar cylindrical shape of the honey stick.

Stage 3: Vertical Sealing

As the film is shaped into a tube, a vertical sealing bar clamps down on the two outer edges of the film. This heated bar fuses the edges together, creating the long, continuous seam that forms the backbone of the stick.

Stage 4: Precise Filling

With the vertical tube now formed, a filling nozzle connected to the honey hopper descends into the tube. A piston or pump mechanism dispenses a precise, pre-measured volume of honey into the packaging. This ensures every stick contains the same amount of product.

Stage 5: Horizontal Sealing and Cutting

A pair of horizontal sealing jaws then comes together to perform two critical tasks at once. It seals the top of the just-filled stick while simultaneously creating the bottom seal for the next stick above it. A small cutting blade, often integrated with the sealing jaw, then slices through the sealed area to separate the finished honey stick, which is then discharged from the machine.

Key Machine Variations and Their Impact

Not all honey stick machines are identical. The technology is adapted to fit different production scales and marketing goals, directly impacting output, cost, and product appearance.

Standard vs. Multi-Lane Automatic Machines

A standard machine typically produces one honey stick at a time and is suitable for smaller operations. In contrast, a multi-lane automatic machine first slits the master film roll into several narrower ribbons, feeding each one into its own forming, filling, and sealing lane. This allows for massive output suitable for large-scale production.

Shaped Honey Stick Machines

These specialized machines use custom-shaped sealing jaws to create unique patterns or styles on the ends of the sticks. While they require a higher initial investment, the unique appearance can enhance marketability and brand differentiation, especially when targeting younger consumers.

Understanding the Trade-offs

While highly efficient, operating a honey stick machine requires an understanding of its technical limitations and operational requirements to achieve optimal performance.

Viscosity and Temperature Control

Honey's thickness (viscosity) changes dramatically with temperature. To ensure consistent and accurate filling, the machine's hopper must be heated to keep the honey at an optimal, flowable temperature. Failure to control this can lead to inaccurate doses and production jams.

Film Material Compatibility

The sealing bars are calibrated for specific temperatures and pressures. Using a packaging film that is not compatible with the machine's settings can result in weak seals that leak or seals that are too strong and damage the film.

Investment vs. Production Scale

The high efficiency of automated, multi-lane machines comes at a significant cost and requires more floor space. Operations must carefully balance the need for high output with the capital investment required, as a smaller machine may be more profitable for a lower-volume business.

Making the Right Choice for Your Operation

Selecting the appropriate machine depends entirely on your business goals, production volume, and target market.

- If your primary focus is entering the market or small-batch production: A standard, single-lane machine offers the best balance of affordability and functionality.

- If your primary focus is high-volume, efficient output for wholesale: A multi-lane automatic machine is essential to meet production demands and lower per-unit labor costs.

- If your primary focus is brand differentiation and retail appeal: A shaped honey stick machine can create a premium product that stands out, justifying the higher initial investment.

Understanding this process transforms the machine from a complex apparatus into a strategic tool for efficient and marketable honey packaging.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Material Loading | Film and honey are loaded. | Prepares raw materials for processing. |

| 2. Tube Forming | Flat film is shaped into a cylinder. | Creates the basic structure of the stick. |

| 3. Vertical Sealing | Heated bar seals the long seam. | Forms a continuous, leak-proof tube. |

| 4. Precise Filling | Nozzle dispenses a measured honey dose. | Ensures consistent product volume in each stick. |

| 5. Sealing & Cutting | Jaws seal and cut the stick. | Separates the finished, individual unit. |

Ready to streamline your honey packaging and boost your production efficiency? At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the right honey stick machines for their scale. Whether you need a standard machine for small-batch production or a high-speed multi-lane system for wholesale volumes, our expertise ensures you get a reliable solution that maximizes your output and ROI. Contact our team today to discuss your needs and get a tailored recommendation!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- What role does industrial-grade honey filling equipment play in large-scale honey production? Scaling for Global Export

- How does the use of standardized honey-filling machines improve distribution efficiency? 5 Key Benefits for Scale

- How does a liquid filling machine work? A Guide to Precise & Efficient Liquid Packaging

- What role do honey filling machines play for high-yield crops? Optimize Your Italian Squash Honey Value Chain

- How do honey filling and packaging machines assist in increasing the added value of beekeeping products for brands?

- What are the core advantages of using high-precision honey-filling machines? Enhance Your Honey Processing Value Chain

- What function does precision filling equipment serve in raw honey repackaging? Optimize Yield and Ensure Compliance

- What are the key advantages of using a honey stick machine in production? Optimize Your Beekeeping Business