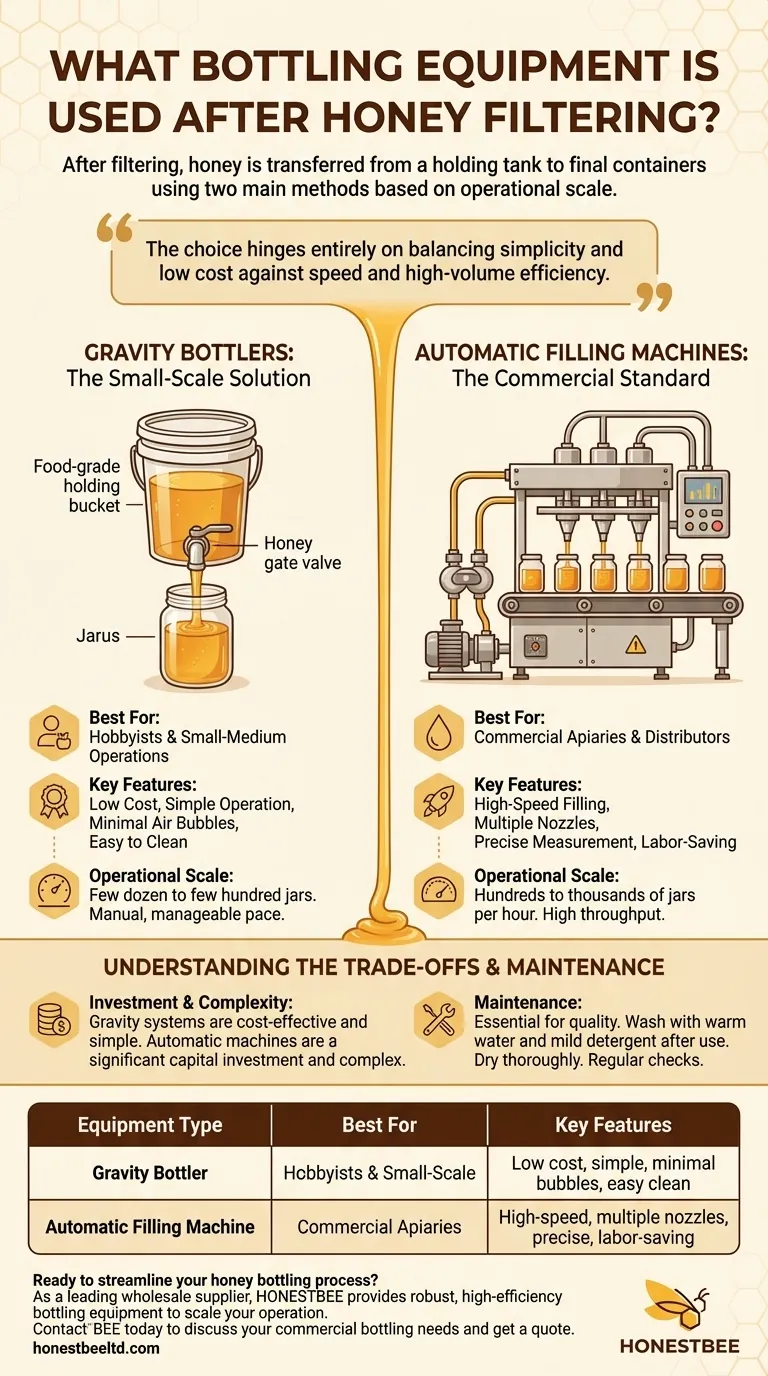

After filtering your honey, the primary equipment used for bottling falls into two main categories: gravity bottlers for smaller operations and automatic filling machines for commercial-scale production. Both are designed to transfer the finished, clean honey from a holding tank into its final containers for sale, gifting, or storage.

The choice between honey bottling methods is not about which is "better," but which tool correctly matches your operational scale. The decision hinges entirely on balancing simplicity and low cost against speed and high-volume efficiency.

The Role of Bottling in Honey Production

Bottling is the final, critical step that transforms your extracted and filtered honey into a finished product. After impurities and wax particles have been removed through filtering, the bottling equipment ensures the honey is packaged cleanly and consistently.

A Crucial Final Step

Proper bottling maintains the quality established during filtering. It prevents re-contamination and provides a professional presentation, which is essential whether you are selling at a local market or simply sharing your harvest.

Core Bottling Equipment Explained

Your scale of production will directly determine the most appropriate bottling equipment. The two primary types serve very different needs.

Gravity Bottlers: The Small-Scale Solution

A gravity bottler is typically a tank or bucket with a specialized honey gate or valve at the bottom. As the name implies, it uses the force of gravity to fill jars placed underneath the valve.

This method is favored by hobbyists and small-to-medium beekeeping operations. It offers a smooth, controlled fill that minimizes air bubbles and is simple to operate and clean.

Automatic Filling Machines: The Commercial Standard

For commercial operations, an automatic filling machine is the standard. These systems use pumps and often feature multiple nozzles to fill several bottles at once with precise, pre-measured amounts of honey.

These machines drastically save time and labor. They ensure high levels of consistency across thousands of jars, a critical factor for professional brands.

Understanding the Trade-offs

Choosing the right equipment requires an objective look at the costs, benefits, and operational demands of each system.

Operational Scale and Speed

A gravity bottler is perfect for processing a few dozen to a few hundred jars. Its pace is manual but manageable for smaller harvests.

An automatic filler is designed for high-throughput environments. It can process hundreds or thousands of jars per hour, making it indispensable for any serious commercial venture.

Investment and Complexity

Gravity systems are incredibly cost-effective, often consisting of just a food-grade bucket and a honey gate. They are simple to set up, use, and maintain.

Automatic machines represent a significant capital investment. They are more complex, require calibration, and have higher maintenance needs due to their mechanical and electrical components.

Maintaining Equipment Integrity

Regardless of your choice, proper maintenance is non-negotiable for preserving honey quality. All components that contact honey must be washed with warm water and a mild detergent after use.

Ensure all parts are dried thoroughly to prevent corrosion or microbial growth. Regular checks for worn seals or loose fittings will extend the life of your equipment and prevent costly leaks.

Making the Right Choice for Your Operation

Your decision should be based entirely on your production goals and volume.

- If your primary focus is small-batch, hobby-level production: A gravity bottler provides a simple, affordable, and effective solution for beautiful, hand-bottled honey.

- If your primary focus is commercial sales and efficiency: An automatic filling machine is a necessary investment to ensure speed, consistency, and scalability.

Selecting the right bottling equipment ensures your final product reflects the care you've invested throughout the beekeeping season.

Summary Table:

| Equipment Type | Best For | Key Features |

|---|---|---|

| Gravity Bottler | Hobbyists & Small-Scale Operations | Low cost, simple operation, minimal air bubbles, easy to clean |

| Automatic Filling Machine | Commercial Apiaries & Distributors | High-speed filling, multiple nozzles, precise measurement, labor-saving |

Ready to streamline your honey bottling process?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the robust, high-efficiency bottling equipment you need to scale your operation. We help you maximize output and ensure consistent, professional packaging for your honey products.

Contact HONESTBEE today to discuss your commercial bottling needs and get a quote on the right equipment for your business.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do high-standard honey filling and sealing machines contribute to honey quality? Secure Your Export Standards

- What technical advantages do industrial honey filling machines provide? Boost Precision and Quality in Processing

- How do high-precision honey filling machines enhance commercial value? Maximize ROI & Product Integrity

- What is the importance of professional honey processing and honey-filling machinery? Elevate Your Apiary's Value

- Why is the use of automated honey filling machines essential for commercial honey distribution? Scale Your API Business

- How does the honey stick machine benefit the confectionery industry? Boost Efficiency and Meet Consumer Demand

- How do professional-grade honey-filling machines contribute to the economic efficiency of an apiary? Boost Your ROI

- What are the benefits of automated honey filling and packaging? Scale Your Apiary with Industrial Precision