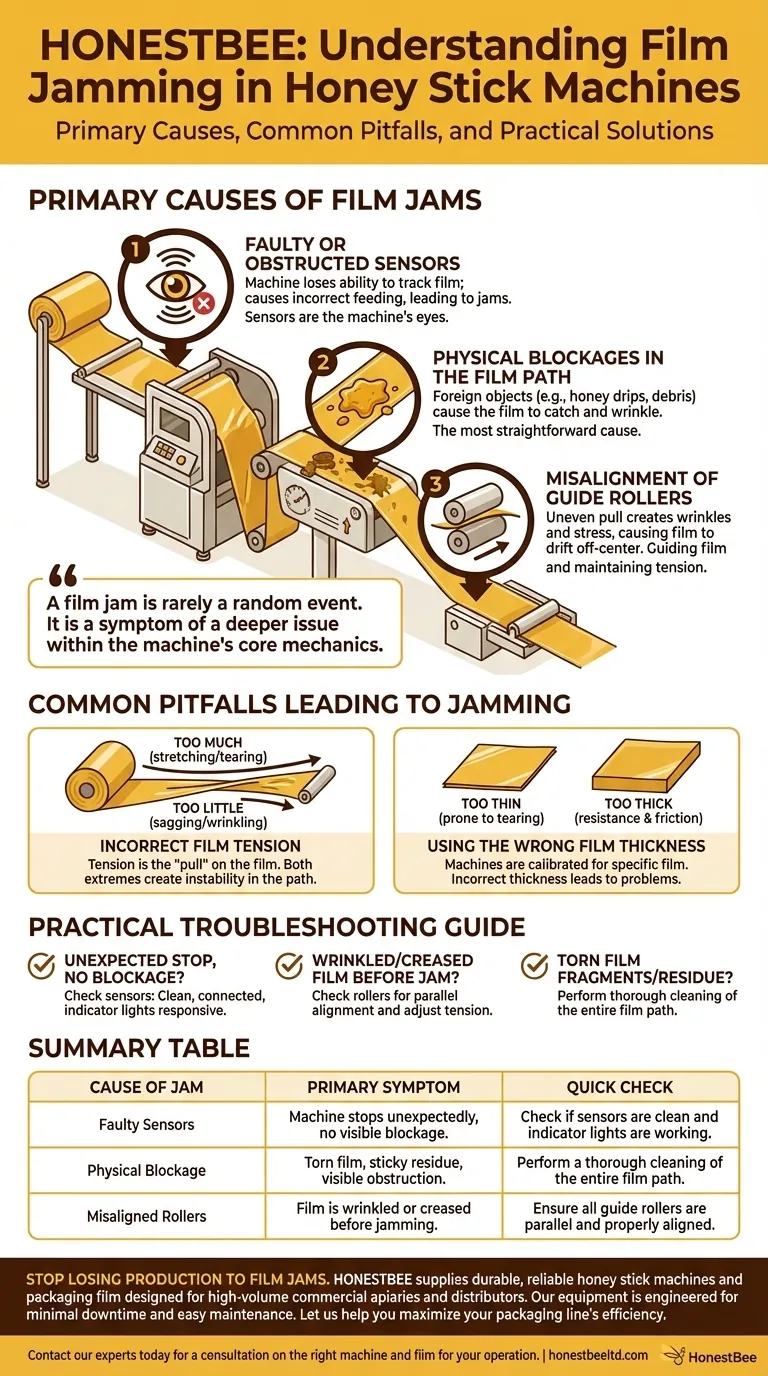

The primary causes of film jamming in a honey stick machine are almost always tied to three specific areas: malfunctioning sensors, a physical blockage in the film's path, or misaligned rollers. These issues disrupt the delicate, continuous flow of packaging material required for smooth operation, leading to costly downtime.

A film jam is rarely a random event. It is a symptom of a deeper issue within the machine's core mechanics—specifically, a breakdown in the system responsible for guiding, sensing, and tensioning the packaging film.

Unpacking the Primary Causes of Film Jams

To effectively troubleshoot and prevent film blockages, you must understand how each component contributes to the process. The film path is a precise system where every part has a critical role.

Faulty or Obstructed Sensors

Sensors are the machine's eyes. They detect the position of the film, ensuring it feeds at the correct rate and stops at the right moment for sealing.

When a sensor is out of order—either dirty, damaged, or electronically faulty—the machine loses its ability to track the film. This can cause it to feed too much material, not enough, or at the wrong time, inevitably leading to a jam.

Physical Blockages in the Film Path

This is the most straightforward cause. Any foreign object or residue in the path the film travels can cause it to catch, wrinkle, and ultimately jam.

Common culprits include hardened honey drips, fragments from previous film tears, or dust and debris. A thorough cleaning of the entire film path is often the simplest fix.

Misalignment of Guide Rollers

The rollers are responsible for guiding the film and maintaining its tension and alignment from the roll to the sealing mechanism. Think of it like the film in an old movie projector.

If even one roller is slightly misaligned, it will pull the film unevenly. This creates wrinkles, puts stress on the material, and causes it to drift off-center, leading directly to a blockage or tear.

Common Pitfalls That Lead to Jamming

While not direct causes of a jam, certain operational errors create the conditions that make jams far more likely. Addressing these is key to preventative maintenance.

Incorrect Film Tension

Tension is the "pull" on the film as it moves through the machine. Too much tension can stretch or tear the film, while too little tension will cause it to sag and wrinkle.

Both scenarios create instability in the film path, significantly increasing the likelihood that the film will fold over on itself or drift into a position that causes a jam.

Using the Wrong Film Thickness

Packaging machines are calibrated for a specific type and thickness of film. Using a film that is too thin can make it prone to tearing and wrinkling under normal tension.

Conversely, film that is too thick may not move smoothly through the guide rollers or seal properly, creating resistance and friction that can result in a blockage.

A Practical Troubleshooting Guide

When a jam occurs, approach the problem systematically to identify the true root cause and prevent a recurrence.

- If the machine stops unexpectedly with no visible blockage: Your first check should be the sensors. Ensure they are clean, properly connected, and their indicator lights respond correctly to the presence of film.

- If the film is wrinkled or creased before the jam point: The most likely cause is misaligned rollers or incorrect film tension. Check that all rollers are parallel and adjust the tension settings.

- If you find torn film fragments or sticky residue: The issue is a physical blockage. Conduct a complete cleaning of the film path, paying close attention to rollers and guide plates.

Ultimately, ensuring your machine is clean, correctly aligned, and using the specified materials is the most effective strategy for preventing film jams.

Summary Table:

| Cause of Jam | Primary Symptom | Quick Check |

|---|---|---|

| Faulty Sensors | Machine stops unexpectedly, no visible blockage. | Check if sensors are clean and indicator lights are working. |

| Physical Blockage | Torn film, sticky residue, visible obstruction. | Perform a thorough cleaning of the entire film path. |

| Misaligned Rollers | Film is wrinkled or creased before jamming. | Ensure all guide rollers are parallel and properly aligned. |

Stop losing production to film jams. HONESTBEE supplies durable, reliable honey stick machines and packaging film designed for high-volume commercial apiaries and distributors. Our equipment is engineered for minimal downtime and easy maintenance. Let us help you maximize your packaging line's efficiency.

Contact our experts today for a consultation on the right machine and film for your operation.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

People Also Ask

- What are the production advantages of using automated honey-filling machines in high-yield beekeeping regions?

- What role does automated honey-filling machinery play? Scale Production and Precision for Commercial Apiaries

- Why are industrial-grade honey-filling machines essential? Boost Your Commercial Scale and Export Efficiency

- Why is the use of professional honey extraction and honey-filling machines emphasized? Boost Quality & Efficiency

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What role do automated honey-filling machines play in the commercial honey production chain? Scaling Your Output Safely

- What type of filling system is typically used in honey filling machines? Master High-Viscosity Liquid Packaging

- What steps should be taken to find a reliable manufacturer for a honey stick machine? Expert Sourcing Guide