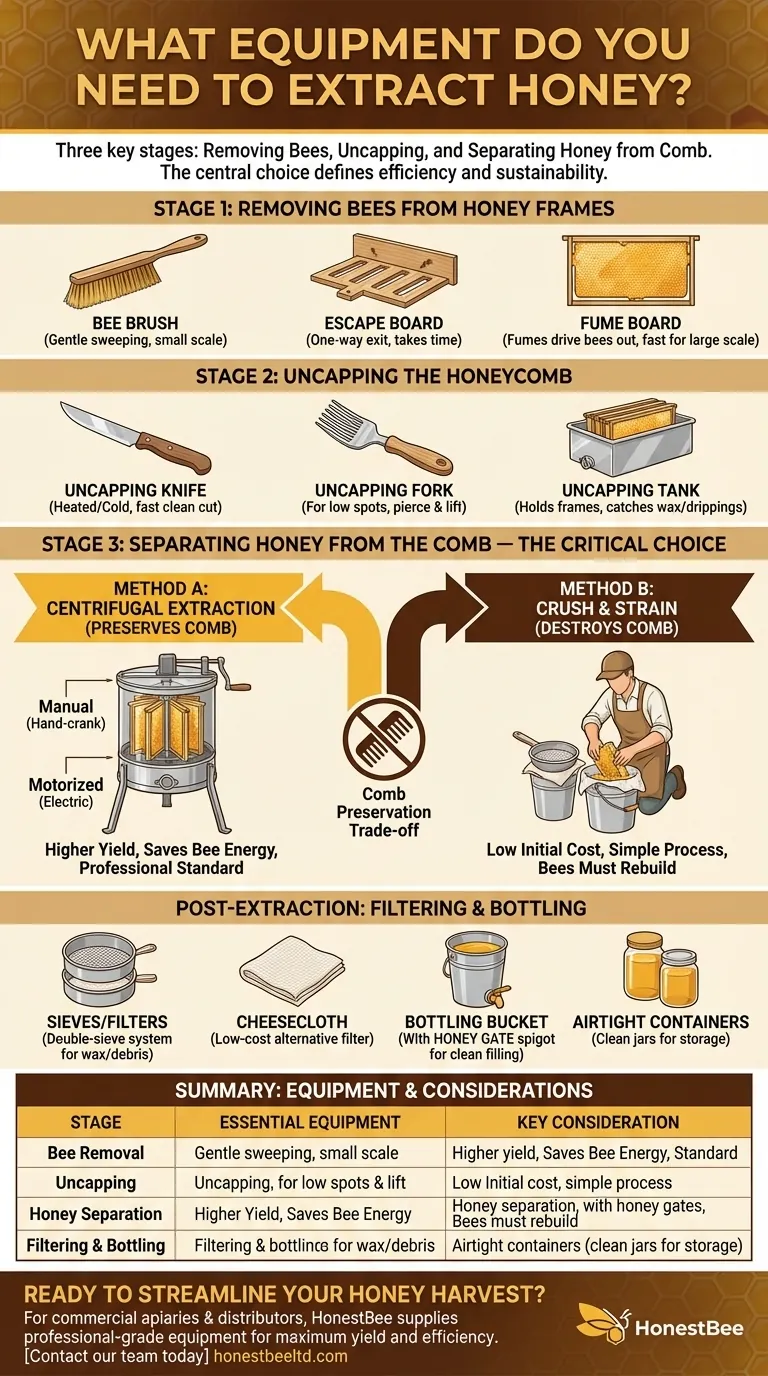

To extract honey, you need equipment for three key stages: removing bees from the frames, uncapping the wax-sealed honeycomb, and separating the liquid honey from the comb. The essential tools include a method to clear bees (like a bee brush), an uncapping tool (like a knife or fork), and a way to get the honey out, which can range from a simple bucket and filter to a mechanical honey extractor.

Your choice of honey extraction equipment is not just a shopping list; it's a decision that defines the scale, efficiency, and sustainability of your beekeeping operation. The central choice is whether to invest in a centrifugal extractor to preserve your comb or to use the simpler crush-and-strain method, which destroys it.

The Honey Extraction Process: A Tool for Every Step

Successfully harvesting honey is a systematic process. Each piece of equipment serves a specific purpose in moving from a full hive to a jar of clean, liquid honey.

Stage 1: Removing Bees from the Honey Frames

Before you can work, you must safely and gently move the bees out of the honey supers (the boxes containing the honey frames).

- Bee Brush: A simple, soft-bristled brush used to gently sweep remaining bees off a frame. This is best for those with only one or two hives.

- Escape Board: A special inner cover with a one-way exit. You place it between the honey supers and the brood box a day before extraction, allowing bees to move down into the hive without being able to return.

- Fume Board: A board with an absorbent cloth on which you place a non-toxic bee repellent. The fumes drive the bees down out of the supers, offering a very fast way to clear a large number of boxes.

Stage 2: Uncapping the Honeycomb

Bees seal each cell of honey with a layer of beeswax. This "capping" must be removed to release the honey. This is typically done in a clean space away from the hives to prevent attracting robbing bees.

- Uncapping Knife: The primary tool for this job. An electric heated knife melts through the cappings for a fast, clean cut, while a cold knife (often serrated and dipped in hot water) is a more affordable option.

- Uncapping Scratcher or Fork: A fork-like tool used to pierce and lift the cappings, especially in low-lying areas of the comb that a knife might miss.

- Uncapping Tank or Bucket: A dedicated container to hold the frames while you work and to catch the wax cappings and dripping honey. The cappings can be further strained to recover a significant amount of honey.

Stage 3: Separating Honey from the Comb

This is the core of the extraction process and where you face the most significant equipment choice. There are two primary methods.

-

Method A: Centrifugal Extraction This method uses a honey extractor, a large drum that spins frames to sling honey out via centrifugal force. Its key advantage is that it preserves the drawn-out honeycomb, saving the bees immense energy on the next nectar flow. Extractors can be manual (hand-cranked) or motorized (electric).

-

Method B: Crush and Strain This low-tech method involves scraping the entire honeycomb off its foundation into a bucket, mashing it up to break open all the cells, and then letting the honey drain out through a series of filters or cheesecloth. It requires minimal specialized equipment but destroys the comb.

Post-Extraction: Filtering and Bottling

Once the honey is out of the comb, it needs to be cleaned and prepared for storage.

Straining and Filtering

Raw honey will contain bits of beeswax, bee parts, and other debris.

- Sieves and Filters: A double-sieve system is common, with a coarse filter on top to catch large wax pieces and a finer filter below. Filters can be made of stainless steel mesh or nylon.

- Cheesecloth: Can be used as a low-cost filter, especially in a crush-and-strain setup.

Bottling and Storage

The final step is getting your clean honey into jars.

- Bottling Bucket: A five-gallon, food-grade bucket with a honey gate (a type of spigot) at the bottom allows for clean, controlled filling of jars without mess.

- Airtight Containers: Honey should be stored in clean, airtight jars or containers to protect it from moisture and contaminants.

Understanding the Trade-offs: Extractor vs. Crush-and-Strain

Your choice between these two methods is the most critical equipment decision you will make. It hinges on balancing cost, effort, and your long-term beekeeping goals.

The Case for Centrifugal Extraction

This is the standard for any beekeeper with more than a couple of hives or those who prioritize hive productivity. By preserving the comb, you give your bees a massive head start, allowing them to focus on nectar collection rather than wax building. The initial cost is higher, but the long-term yield is greater.

The Case for Crush and Strain

This is an excellent entry point for beginners with only one or two hives. The initial investment is extremely low, and the process is straightforward. However, forcing the bees to rebuild all of their comb every year significantly reduces their potential honey surplus.

Making the Right Choice for Your Apiary

Base your equipment decisions on your specific goals and the scale of your operation.

- If your primary focus is a low-cost first harvest from 1-2 hives: Start with the crush-and-strain method using buckets, a spatula, and filters.

- If your primary focus is preserving comb and growing your apiary: Invest in a small, manual hand-crank extractor and an uncapping knife or fork.

- If your primary focus is efficiency with several established hives: A motorized extractor, a heated uncapping knife, and a dedicated uncapping tank will save you significant time and labor.

Choosing the right tools empowers you to perform a clean, efficient, and rewarding honey harvest.

Summary Table:

| Extraction Stage | Essential Equipment | Key Consideration |

|---|---|---|

| Bee Removal | Bee Brush, Escape Board, Fume Board | Choose based on speed and number of hives. |

| Uncapping | Heated/Cold Knife, Uncapping Fork | Heated knives offer faster, cleaner cuts. |

| Honey Separation | Centrifugal Extractor (Manual/Electric) or Crush-and-Strain Buckets | Extractor preserves comb; crush-and-strain is low-cost but destroys it. |

| Filtering & Bottling | Sieves/Filters, Bottling Bucket with Honey Gate | Ensures clean, debris-free honey for storage. |

Ready to streamline your honey harvest? For commercial apiaries and distributors, the right equipment is not just a purchase—it's an investment in productivity and sustainability. HONESTBEE supplies professional-grade beekeeping equipment through wholesale-focused operations, helping you maximize yield and efficiency. Contact our team today to discuss your specific needs and scale your operation.

Visual Guide

Related Products

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- How do automated honey extractors contribute to an increased honey yield? Boost Your Apiary's Production Efficiency

- What is the primary function of a honey extractor motor in beekeeping? Boost Efficiency & Protect Honeycomb

- What are the technical benefits of using centrifugal honey extraction equipment? Maximize Your Yield and Efficiency

- How does using a honey extractor help protect honeycombs? Maximize Hive Efficiency and Preserve Wax Structure

- Can you extract honey without killing bees? A Guide to Ethical, Bee-Centric Harvesting

- How does a honey extractor work to harvest honey? Master the Centrifugal Force for Efficient Beekeeping

- What are the benefits of using a centrifugal honey extractor? Boost Efficiency and Preserve Your Beehive's Energy

- What role does the Centrifugal Honey Extractor play in honey post-processing? Maximize Your Harvest Efficiency