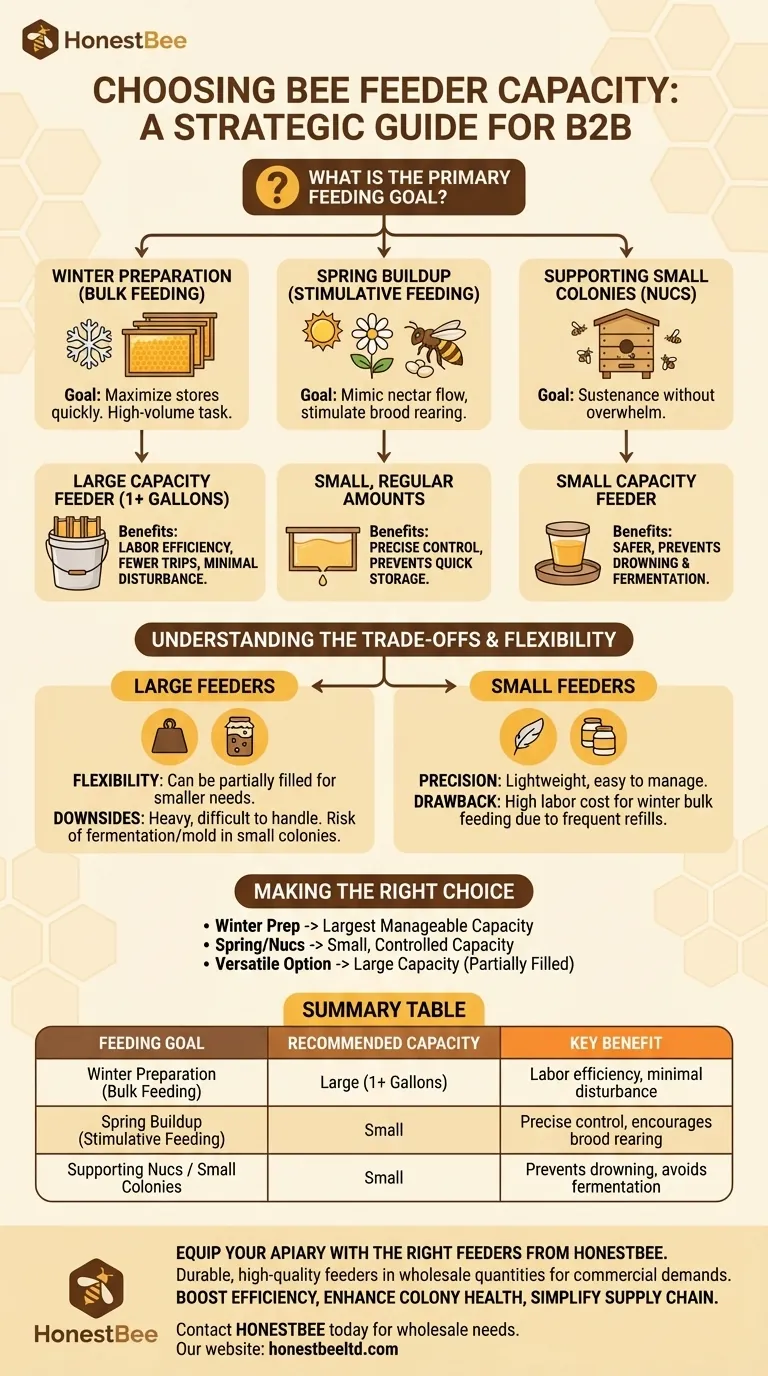

The primary factor influencing the choice of a bee feeder's capacity is the specific goal of the feeding. The volume of feed a colony needs is dictated by whether you are trying to provide winter stores in bulk, stimulate brood rearing in the spring, or support a small, developing colony.

The decision is a trade-off between labor efficiency and control. Large-capacity feeders are ideal for providing massive stores with minimal visits, while smaller-capacity feeders offer precise control for stimulating growth or supporting weaker hives.

The Core Principle: Matching Capacity to Your Goal

Your reason for feeding the bees directly determines how much syrup they need at one time. Different beekeeping objectives require vastly different volumes and delivery schedules.

For Bulk Feeding (Winter Preparation)

When preparing a colony for winter, the goal is to have them store a large quantity of sugar syrup as quickly as possible. This is a high-volume task.

A large capacity feeder is highly advantageous here. Using a feeder that holds one or more gallons allows you to fill the hive's pantry with fewer trips, minimizing both your labor and the disturbance to the colony.

For Stimulative Feeding (Spring Buildup)

In the spring, the goal is not to fill the hive with stores, but to mimic a natural nectar flow. This encourages the queen to ramp up her egg-laying.

This requires giving the bees small, regular amounts of thin syrup. A smaller feeder is often better for this, as it prevents the bees from storing the syrup too quickly and filling cells the queen needs for laying.

For Supporting Small Colonies (Nucleus Hives)

A small or newly established colony, known as a nucleus or "nuc," cannot consume large volumes of feed at once. They can be easily overwhelmed.

A smaller capacity feeder is sufficient and safer for these colonies. It provides the sustenance they need to draw comb and grow without the risk of large-scale drowning or syrup fermentation.

Understanding the Trade-offs

While the goal is the primary driver, practical considerations and the inherent flexibility of different feeders also play a role in the decision.

The Advantage of Flexibility

A key point to remember is that a large feeder can always be partially filled. This gives a beekeeper flexibility.

If you can only own one type of feeder, a larger one may be the better investment, as it can serve for bulk winter feeding and be used with smaller amounts for stimulative purposes.

The Drawbacks of Large Capacity

While flexible, large feeders are not without potential downsides. They can be heavy and difficult to handle when full.

Furthermore, if a large volume of syrup is given to a colony that is too small to consume it quickly, the syrup may begin to ferment or grow mold.

The Case for Smaller Feeders

Smaller feeders are lightweight, easy to manage, and ideal for the precise control needed for stimulative feeding.

Their primary disadvantage is the high labor cost for winter preparation. Topping up a full-sized hive for winter with a small feeder would require numerous refills, causing significant and repeated disturbance to the bees.

Making the Right Choice for Your Colony

Ultimately, the optimal feeder capacity aligns directly with the task at hand.

- If your primary focus is preparing strong, full-sized colonies for winter: Choose the largest capacity feeder you can manage to reduce your workload and hive intrusions.

- If your primary focus is stimulating spring growth or supporting a small nucleus hive: A small capacity feeder provides better control and safety for the colony.

- If you need a single, versatile option: A large capacity feeder that can be partially filled offers the most flexibility for different seasonal needs.

Choosing the right equipment is about making your management practices more effective and beneficial for the bees.

Summary Table:

| Feeding Goal | Recommended Capacity | Key Benefit |

|---|---|---|

| Winter Preparation (Bulk Feeding) | Large (1+ Gallons) | Labor efficiency, minimal disturbance |

| Spring Buildup (Stimulative Feeding) | Small | Precise control, encourages brood rearing |

| Supporting Nucs / Small Colonies | Small | Prevents drowning, avoids fermentation |

Equip Your Apiary with the Right Feeders from HONESTBEE

Choosing the correct feeder capacity is a critical step in effective apiary management. Whether you are a commercial beekeeper preparing hundreds of hives for winter or a distributor supplying equipment to the trade, having the right tools saves time and promotes colony health.

HONESTBEE supplies durable, high-quality beekeeping feeders and equipment in wholesale quantities, perfectly suited for the demands of commercial apiaries and distributors. We help you:

- Boost Efficiency: Reduce labor costs with appropriately sized equipment for every task.

- Enhance Colony Health: Provide the right support at the right time, from nucs to full-strength hives.

- Simplify Your Supply Chain: Get all your feeding solutions from a single, reliable wholesale partner.

Ready to optimize your feeding strategy? Contact HONESTBEE today to discuss your specific needs and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- HONESTBEE Entrance Bee Feeder Professional Hive Nutrition Solution for Beekeeping

- Professional Hive Front Entrance Bee Feeder

- Classic Boardman Entrance Bee Feeder Hive Front Feeding Solution

- HONESTBEE Professional Entrance Bee Feeder Hive Nutrition Solution

People Also Ask

- What safety features are included in top feeders? A Guide to Drowning Prevention and Hive Safety

- Do I need an inner cover with a hive top feeder? Optimize Your Hive Setup for Healthy Bees

- How do I keep bees from drowning in my top feeder? Ensure Safe Feeding for Your Hive

- Why is a top feeder essential for bees? Ensure Colony Health and Efficiency

- What are the advantages of using Top Feeders? Boost Commercial Apiary Efficiency with High-Capacity Feeding Solutions