Choosing the right honey extractor is a critical decision for any beekeeper, directly impacting the efficiency and enjoyment of your harvest. The primary factors to consider are the number of hives you manage, your budget, the physical space you have for operation and storage, and how much time you are willing to spend. A larger extractor costs more and requires more space, but it processes frames much faster, saving significant labor.

Your choice of an extractor is an investment in your time. The central goal is to select a size that not only fits your current apiary but also accommodates your realistic growth over the next few years, preventing you from buying a tool you will quickly outgrow.

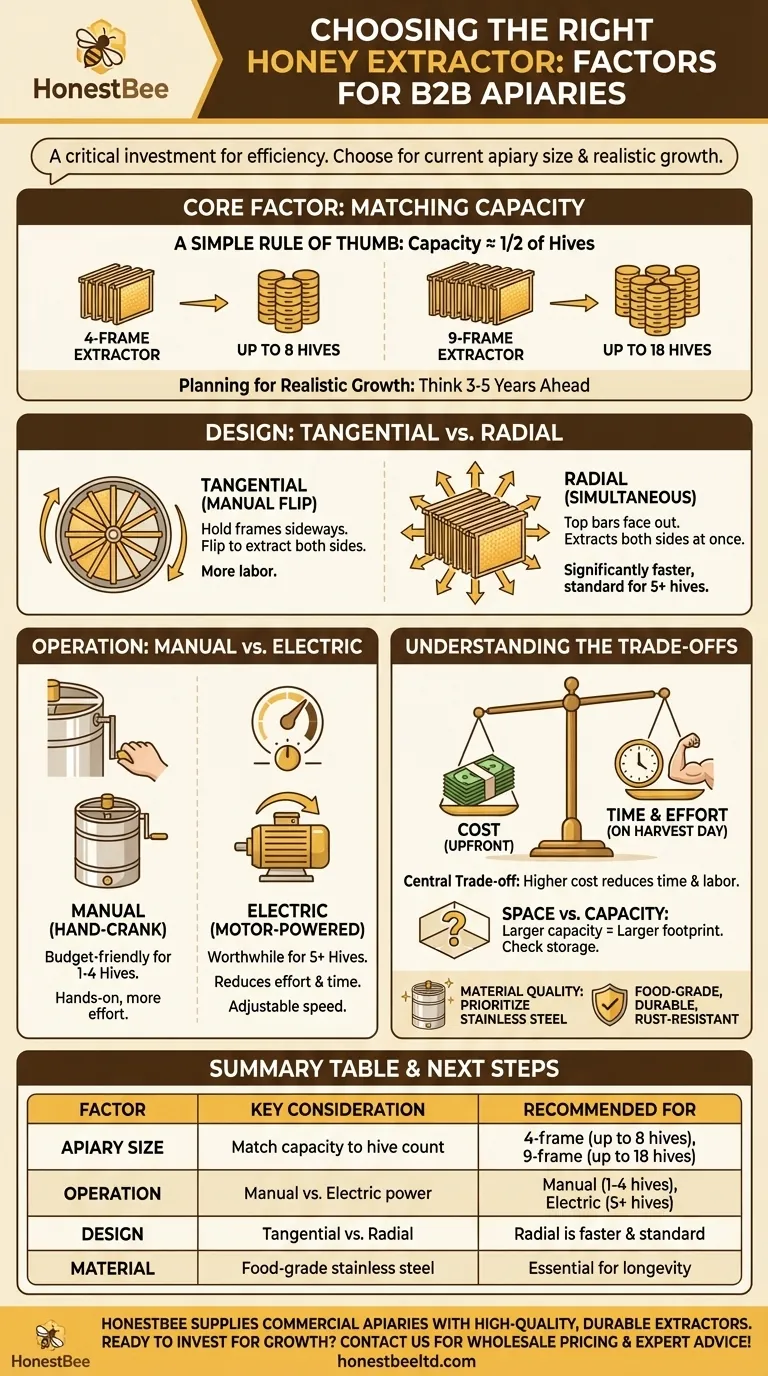

The Core Factor: Matching Capacity to Your Apiary

The most important variable in your decision is the number of hives you manage. This dictates the frame capacity you will need to make honey extraction a manageable task rather than an overwhelming one.

A Simple Rule of Thumb

A common guideline is that an extractor can comfortably support about double the number of hives as its frame capacity.

For example, a 4-frame extractor is generally suitable for an apiary of up to 8 hives. A 9-frame extractor can handle the harvest from approximately 18 hives. This isn't a rigid rule, but it provides a reliable starting point for assessing your needs.

Planning for Realistic Growth

Avoid the common mistake of buying only for the hives you have today. Consider where your apiary will be in three to five years.

If you currently have two hives but plan to expand to ten, buying a small 2-frame extractor will create a significant bottleneck in the future. Investing in a slightly larger model now saves you from needing to upgrade later.

Tangential vs. Radial Design

The extractor's design also impacts efficiency. Tangential extractors hold frames like spokes in a wheel, with one side facing out. You must manually flip the frames to extract honey from both sides.

Radial extractors hold frames with the top bar facing out, allowing honey to be extracted from both sides simultaneously using centrifugal force. They are significantly faster and are the standard for anyone with more than a few hives.

The Next Layer: Manual vs. Electric Operation

After determining frame capacity, the next choice is between manual (hand-crank) and electric power. This decision hinges on balancing cost against labor.

The Case for Manual Extractors

A manual extractor is an excellent, budget-friendly choice for beekeepers with 1 to 4 hives. They are simple, have fewer parts that can break, and offer a hands-on connection to the harvest process.

The Case for Electric Extractors

For anyone managing 5 or more hives, an electric extractor is a worthwhile investment. It dramatically reduces physical effort and saves hours of time. Look for models with adjustable speed controls to prevent damaging delicate new comb.

Understanding the Trade-offs

Choosing an extractor involves balancing competing priorities. Being clear about these trade-offs will lead you to the right decision.

Cost vs. Time

This is the central trade-off. A larger, electric, radial extractor has a high upfront cost but can reduce a full day of hard labor to a few hours of light work. A small, manual extractor is inexpensive but requires a significant commitment of time and physical energy on harvest day.

Space vs. Capacity

A large-capacity extractor is a bulky piece of equipment. You must have adequate room not only to operate it safely but also to store it during the off-season. Measure your available space before committing to a large model.

Material Quality and Longevity

Extractors are typically made from plastic or stainless steel. While plastic models are cheaper, food-grade stainless steel is the superior choice for its durability, rust resistance, and ease of cleaning. A stainless steel extractor is a long-term investment in food safety and equipment longevity.

Making the Right Choice for Your Goal

Your decision should be guided by your specific beekeeping ambitions.

- If your primary focus is a small hobby (1-4 hives): A 2- or 4-frame manual tangential extractor offers a cost-effective and manageable entry point.

- If your primary focus is growing your apiary (5-15 hives): An electric radial extractor with a 4 to 9-frame capacity is the ideal investment for balancing cost and long-term efficiency.

- If your primary focus is maximizing efficiency (15+ hives): A large electric radial extractor (16+ frames) is necessary to process your harvest without creating a major bottleneck.

By aligning your equipment with your ambition, you ensure your honey harvest remains a reward, not a chore.

Summary Table:

| Factor | Key Consideration | Recommended for Hive Count |

|---|---|---|

| Apiary Size | Match extractor capacity to your current and future hive count. | 4-frame for up to 8 hives; 9-frame for up to 18 hives. |

| Operation Type | Choose between manual (hand-crank) or electric power. | Manual for 1-4 hives; Electric for 5+ hives. |

| Design | Select tangential (flip frames) or radial (extract both sides simultaneously). | Radial is significantly faster and standard for most beekeepers. |

| Material | Prioritize food-grade stainless steel for durability and ease of cleaning. | Essential for long-term investment and food safety. |

Ready to invest in the right honey extractor for your apiary's growth?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable extractors designed for efficiency and longevity. Let our experts help you select the perfect model to turn your harvest from a chore into a reward.

Contact HONESTBEE today for wholesale pricing and expert advice!

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation

- What operational benefits do motorized honey extractors provide? Scale Your Harvest Efficiency

- What is the primary function and advantage of a honey extractor? Maximize Yield Through Non-Destructive Harvesting

- Why are honey extractors utilized in the large-scale cultivation of Apis cerana? Boost Yield and Protect Bee Energy

- What advantages does a centrifugal honey extractor offer over traditional pressing methods? Unlock Superior Honey Purity