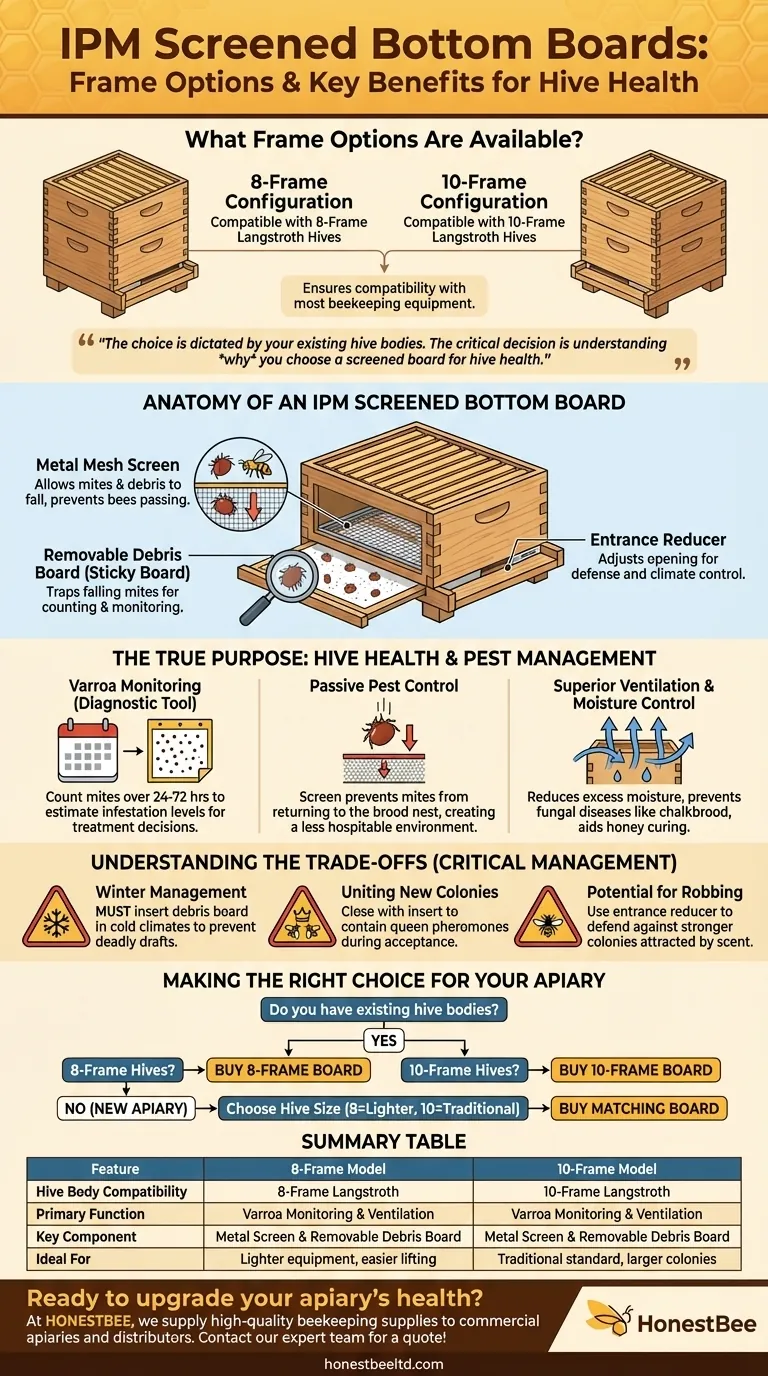

To be direct, IPM (Integrated Pest Management) screened bottom boards are manufactured to fit the two standard Langstroth hive dimensions. You can purchase them in either an 8-frame or a 10-frame configuration. This ensures they are compatible with the vast majority of beekeeping equipment in use today.

The choice between an 8-frame and 10-frame model is dictated entirely by your existing hive bodies. The more critical decision is not the size, but understanding why you are choosing a screened bottom board over a solid one for your hive's health.

What is an IPM Screened Bottom Board?

An IPM screened bottom board is a foundational hive component designed for modern bee management. It replaces the traditional solid wood floor of the hive with a more functional, multi-part system.

The Core Components

A typical IPM screened bottom board is a fully assembled unit that includes a metal mesh screen, a removable debris board, and an entrance reducer. Each part serves a distinct purpose for hive monitoring and health.

The Role of the Screen

The primary feature is the durable metal mesh that makes up the floor. This screen allows varroa mites, hive debris, and excess moisture to fall out of the hive, but is sized to prevent bees from passing through.

The Debris Board (or "Sticky Board")

Underneath the screen slides a removable panel, often made of a material like Corex. By coating this board with a light layer of oil or petroleum jelly, it becomes a "sticky board" that traps falling varroa mites for counting, which is a cornerstone of any IPM strategy.

The True Purpose: Hive Health and Pest Management

While ventilation is a key benefit, the primary function of this board is to give you critical data about the health of your colony, specifically regarding varroa mite infestations.

Monitoring Varroa Mites

The screened bottom board is a diagnostic tool. By inserting the sticky board for a set period (e.g., 24-72 hours) and then counting the trapped mites, you can accurately estimate the infestation level within your colony and make an informed decision about whether treatment is necessary.

Passive Pest Control

When mites lose their grip and fall from a bee, the screen prevents them from climbing back into the brood nest. While not a substitute for active treatment, this creates a less hospitable environment for mites and contributes to a lower overall pest load.

Superior Ventilation and Moisture Control

The screen provides excellent air circulation throughout the hive. This passive ventilation helps reduce excess moisture, which is critical for preventing fungal diseases like chalkbrood and for helping the bees cure honey more efficiently.

Understanding the Trade-offs

While highly beneficial, an IPM screened bottom board requires active management and awareness of its potential downsides.

Critical Winter Management

In cold climates, leaving the screen open during winter can create a deadly draft and cause the colony to expend too much energy trying to stay warm. The debris board must be inserted during winter to close off the bottom and provide insulation.

Uniting New Colonies

When installing a new package of bees or re-queening a hive, the board should be closed with the insert. This helps contain the vital queen pheromones within the hive, promoting acceptance and cohesion during this critical period.

Potential for Robbing

The wide-open ventilation can sometimes make a weaker hive's scent more detectable to robber bees from other colonies. Always use the included entrance reducer to narrow the opening to a size your colony can effectively defend.

Making the Right Choice for Your Apiary

Your decision should be based on your equipment and management goals.

- If you have existing 10-frame hive bodies: You must purchase a 10-frame IPM screened bottom board to ensure a proper fit.

- If you have existing 8-frame hive bodies: You must purchase an 8-frame IPM screened bottom board.

- If you are starting a new apiary: Choose your hive size (8-frame boxes are lighter to lift; 10-frame is the traditional standard) and then buy the matching IPM bottom board.

Choosing the correct IPM screened bottom board is a foundational step toward proactive, data-driven beekeeping.

Summary Table:

| Feature | 8-Frame Model | 10-Frame Model |

|---|---|---|

| Hive Body Compatibility | 8-Frame Langstroth | 10-Frame Langstroth |

| Primary Function | Varroa Mite Monitoring & Ventilation | Varroa Mite Monitoring & Ventilation |

| Key Component | Metal Screen & Removable Debris Board | Metal Screen & Removable Debris Board |

| Ideal For | Lighter equipment, easier lifting | Traditional standard, larger colonies |

Ready to upgrade your apiary's health with the right IPM screened bottom board?

At HONESTBEE, we supply high-quality beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. We provide the durable, precisely manufactured IPM bottom boards you need for effective pest management and superior hive ventilation.

Let us help you make a data-driven choice for your operation. Contact our expert team today to discuss your needs and request a quote!

Visual Guide

Related Products

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- HONESTBEE Professional Frame Wiring Board and Jig

People Also Ask

- How does a screened beehive bottom board assist with non-chemical pest control? Boost Hive Health Naturally

- What is the function of screening bottom boards in large-scale beekeeping management? Boost Colony Health with Data

- What are the benefits of using a screened bottom board and in which climate is it recommended? Optimize Hive Health

- What are the primary functions of a screened beehive bottom board? Optimize Hive Ventilation & Pest Control

- What are the steps to install wire mesh as a floor in a beehive? A Guide to Better Ventilation & Mite Control